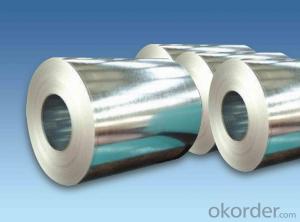

Hot dipped Galvanized Steel Coil ASTM A653

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

HOT DIP GALVANIZED STEEL COIL

Specification:0.55mm*1000mm*c

Steel Grade & Standard: ASTM A653

Zinc Coating Mass:Z180 Spangle:Zero Spangle

Surface Treatment: non-chromate, oiled

Coil ID:508mm Coil Weight:6-10MT

Package Type:EYE TO SIDE

Thickness Tolerance:+/-0.02mm Width Tolerance:+/-5mm

Zinc Coating Tolerance:-/+10g/m2

- Q: How are steel coils coated or painted?

- Steel coils are typically coated or painted using a process called coil coating. In this process, the steel coil is cleaned, treated, and primed before being coated with a layer of paint or a protective coating. This is usually achieved through a continuous automated line, where the coil is unwound, cleaned, coated using various methods such as roller coating or spraying, and then cured to ensure adhesion and durability of the coating. This process allows for efficient and uniform coating application, providing the steel coils with enhanced corrosion resistance and aesthetic appeal.

- Q: Recently I bought Bleach's Grimmjow's replica sword from swordsswords and I was wondering how strong is 440 steel when used for a 21 inch blade? Can it cut effectively? Is it dangerous?

- You were seriously ripped off. I own a 440 stainless sword that I paid $29 for on eBay. It ain't a half bad sword actually, and like you said, I have never failed to cut straw mats with it. The 440 stainless is about as good as you can get without paying for a folded steel katana. However, I also own a Bugei company folded steel katana and the difference is night and day. The balance is better, the edge is incredible (you could literally shave with it) and there's just something....ELSE. There's a different FEEL. It's like the difference between using a tool and a weapon. As far as the shingami, again, you were ripped off. You can buy a traditional shingami from eBay and actually get it from a reputable company and not take your chances with the stuff you find at a mall. Even then, you will only pay maybe $50-$75 for a good set including shipping. Generally speaking, nothing you get from a mall or COULD get from a mall will be as good as something from a reputable company like Bugei. However, like in the case of your katana, some things might be good ENOUGH for you. However, you do need to look around and do some price checking before you drop that much money for anything. Hope this helps... Sensei Cox

- Q: Hi,Well, I live near almost across the street from a forest, and my neighborhood is full of raccoons!!! Recently, I just purchased a bunny and have kept it at my cousin's house for the time being. He has a steel cage, and is about 6 months old. I am considering bringing him home and leaving him in the back yard with his steel cage. I am just afraid that raccoons can bite through the steel and get to him. So the question is... Is is possible for raccoons to bite through steel? Btw,Please don't answer hate comments about me being a bad rabbit owner. I simply want to know if raccoons can bite through steel. If it doesn't work out, the rabbit will stay at my cousins house until further notice. But please, I did not waste 5 points for unneeded answers. Thanksss!

- Well the raccoons can't bite through steel unless it is very thin steel, like aluminum foil thickness. But they have long arms and can reach into the cage so that would be my worry. They are also very clever so I don't know if it is safe for the bunny. That would depend upon the size of the cage and how hungry the raccoons are. The raccoons might be tempted to try to steal the bunny's food so that is a concern. Check with a pet shop owner or forester or someone like that who has knowledge about raccoons in the area.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several types of steel coil surface treatments for corrosion resistance, including galvanizing, zinc coating, chromating, and polymer coating.

- Q: Can steel coils be coated with RFID technology?

- Yes, steel coils can be coated with RFID technology. This technology allows for tracking and identification of the steel coils, improving supply chain management and providing real-time information on their location and status.

- Q: What are the different methods of galvanizing steel coils?

- There are three main methods of galvanizing steel coils: hot-dip galvanizing, electro-galvanizing, and continuous galvanizing. Hot-dip galvanizing involves immersing the steel coil in a bath of molten zinc, providing a thick and durable coating. Electro-galvanizing uses an electrical current to deposit a thin layer of zinc onto the steel surface. Continuous galvanizing is a process where the steel coil is continuously passed through a series of zinc baths, resulting in a uniform coating.

- Q: What are the end uses of galvanized steel coil? What is the market like for this raw material? Would something like this be expensive?Also can you explain: PPGI.And the following specifications; what do they mean/represent?Required Composition :Thickness- 0.23mmCarbon- Max. 0.01%Manganese- Max. 0.20%Phosphorous- Max. 0.05%Sulphur- Max. 0.01%Silicon- ABT. 2.80 - 3.50%CRGO Quality- Prime QualityThanks

- Steel coil is the name given to thinner sheet steel when it is manufactured - it comes out of the machine and is formed into a coil for ease of handling storage and transportation. Thin sheet steel is used for plenty of stuff. It can be slit (cut) into thin strips as well as just cropped and used at one of the standard lengths x widths it leaves the mill. There is a big market for this material. It is used in many construction and engineering applications for things like ducting, boxes, gutters, down pipes, flashings, panels, car bodies etc., anything made of thin steel Galvanising is a flash coating of zinc which improves it's corrosion resitance. Cost wise it is a relatively cheap material. The chemical composition of steel varies, it is mostly iron but has various other elements added or present as impurities that change it's characteristics, depending on the end use. These additional elements can be selected to give better weld ability, hardness, tensile strength, corrosion resistance, flexibility and so on. In many applications excess of these chemicals is undesirable. For example sulphur and carbon are generally better at lower levels. The chemical composition data is contained in a material data sheet and expressed as a percentage of the chemical present and which gives the composition of a particular batch of steel, allowing it to be selected for particular applications and traced for quality assurance purposes. The list you have there shows presence and quantity of other elements in a particular batch of coil. The thickness is 0.23mm, quite thin.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Factors such as mishandling, improper stacking, exposure to moisture or extreme temperatures, and inadequate packaging can lead to dents, scratches, corrosion, and even deformation of the coils. Adequate precautions and secure packaging are necessary to minimize the risk of damage during storage or transportation.

- Q: Explain your answers please. I was watching mythbusters and they bought a steel coffin over a wooden one because they thought it would hold more dirt. Now how come bridges that have been made of wood lasted way longer than steel bridges? Or rollercoasts for example.

- Back when I was in school we used to have a contest comparing balsa wood bridge designs. The idea was to build the strongest bridge when derated for bridge weight. The strength test was that the 2-ft long bridge was placed between two tables and a garbage can was strung up to the middle of it. Then it was slowly filled with water until the bridge snapped. The can was weighed and divided by the bridge weight to get our scores. I don't see why you couldn't do this to compare wood vs steel. You could find how much load is needed to snap sample rods. The important point is that the rods should be nearly identical in dimensions between the two materials-- this means length and diameter. Also if you're measuring steel, you'd want to choose a relatively thin diameter or a long span or you won't be able to even bend it. Also while I'm pretty sure wood will snap, steel might bend gradually, so you'd have to decide how much deformation you would allow before calling the piece failed. Also if you take this approach be sure to wear safety glasses when running it. In fact it would be a good idea to put a metal shroud around the test structure.

- Q: I just started playing guitar last year. I never changed the chords. When my sister started taking guitar lessons her teacher said that she needed to change the chords. When i bought the guitar it came with steel strings but i bought nylon strings because they are easier on the fingers. The problem is i already tuned up the guitar but it sounds really bad like if it was not tuned. What can i do about this?

- Both are designed deferentially, they have their own sound and music distinction and so as their string you should use what is appropriate to them.

Send your message to us

Hot dipped Galvanized Steel Coil ASTM A653

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords