Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

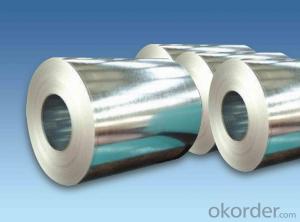

1.Description of Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard:

Hot dip galvanized steel coil products mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce industries ect.In construction industry, hot dip galvanized steel coil is mainly used to manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille, etc.

2.Specifications of Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard:

(1) Light industries use hot dip galvanized steel coil to make home appliance’s case, civil chimney, kitchen utensils, etc.

(2) Auto industry mainly use hot dip galvanized steel coil to produce corrosion resistant parts of cars

(3) Agriculture, animal husbandry, and fishery mainly use hot dip galvanized steel coil for food storage, meat and aquatic products’ freezing and processing equipment etc;

(4) In commerce, hot dip galvanized steel coil is mainly used as the equipments to store and transport materials, and packing implements.

3.Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard Images:

4.Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard Specification:

Specification(mm) | Reference length | Specification(mm) | Reference length |

0.18*1000 | 710m | 0.18*1200 | |

0.23*1000 | 553m | 0.23*1200 | 461m |

0.25*1000 | 509m | 0.25*1200 | 425m |

0.276*1000 | 472m | 0.276*1200 | 393m |

0.30*1000 | 424m | 0.30*1200 | 354m |

0.326*1000 | 398m | 0.326*1200 | 331m |

0.35*1000 | 364m | 0.35*1200 | 303m |

0.376*1000 | 335m | 0.376*1200 | 279m |

0.40*1000 | 318m | 0.40*1200 | 265m |

0.426*1000 | 303m | 0.426*1200 | 252m |

0.45*1000 | 285m | 0.45*1200 | 237m |

0.476*1000 | 271m | 0.476*1200 | 226m |

0.50*1000 | 254m | 0.50*1200 | 212m |

0.60*1000 | 212m | 0.60*1200 | 177m |

5.PACKING:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the industries that consume the most steel?

- I'm guessing manufacturing

- Q: What are the different types of steel coil cutting methods?

- There are several different types of steel coil cutting methods, including slitting, shearing, and laser cutting. Slitting involves cutting the coil into narrower strips using rotating circular knives. Shearing is the process of cutting the coil using straight blades to create straight edges. Laser cutting uses a focused laser beam to melt and vaporize the steel, resulting in a precise and clean cut.

- Q: What are the factors affecting the lifespan of steel coils?

- The lifespan of steel coils can be influenced by various factors. To begin with, the quality of the steel utilized in the coil manufacturing process plays a significant role. Steel of high quality, possessing appropriate composition and metallurgical properties, tends to have a longer lifespan in comparison to lower-quality steel. Moreover, the environment in which the steel coils are stored and utilized also impacts their longevity. Exposure to extreme temperatures, humidity, and corrosive substances can result in the degradation and corrosion of the coils, ultimately reducing their lifespan. To prolong the lifespan of the coils, it is crucial to maintain proper storage conditions, including controlled temperature and humidity levels. Additionally, the handling and transportation of steel coils can have an effect on their lifespan. Mishandling, such as dropping or improper loading and unloading, can lead to physical damage, causing premature failure of the coils. Similarly, rough transportation conditions characterized by excessive vibration or impact can contribute to coil deterioration and a reduction in their lifespan. Furthermore, the maintenance and care of the steel coils also play a role in determining their lifespan. Regular inspections, cleaning, and maintenance practices aid in the identification and resolution of potential issues before they escalate into major problems. Moreover, applying protective coatings or treatments to the coils can prevent corrosion and extend their lifespan. In summary, the lifespan of steel coils is influenced by a combination of factors, including steel quality, storage conditions, handling and transportation, and maintenance practices. It is essential to consider these factors and implement appropriate measures to ensure the longevity of the coils.

- Q: How do steel coils contribute to sustainability in construction?

- Steel coils contribute to sustainability in construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel coils have a longer lifespan and require fewer repairs and replacements. This reduces the overall environmental impact associated with construction activities. Additionally, steel is a highly recyclable material, with most steel coils containing a significant amount of recycled content. This promotes a circular economy and reduces the demand for new raw materials. Moreover, steel coils are lightweight and versatile, allowing for more efficient transportation and installation, thereby reducing energy consumption and emissions during construction. Overall, the use of steel coils in construction promotes sustainability by offering durability, recyclability, and energy efficiency.

- Q: Hi all.I'm working on a project which requires about 3 steel pipes at 25mm in diametre and about a foot each in length.The qualities I need with the steel is that:1. I need it to be easy enough to weld together2. I need to be able to drill holes through them with a basic drill (I could buy different bits, that's fine)3. I need the steel to be able to take short intense repeated bursts of strain through said holes4. The lighter the steel the better5. Could I please have a ballpark figure for price. I can't imagine such a small amount of steel would cost too muchThank you in advance for your replyRegardsSean

- For a structural product you want tubing instead of pipe. ERW (Electric resistance welded) steel tubing is generally a fairly good compromise between cost and strength. They are available in various wall thicknesses for either lighter weight or greater strength. DOM (dimensioned over mandrel) tubing generally uses a stronger steel allow and is more dimensionally uniform but the cost is much higher. These products are probably available at a local steel supplier. They are both mild steel so they can be arc welded or brazed with ease. Strength of these steel alloys is generally about 70,000 psi so you need to analyze the specific applied stress over the specific surface area to determine what wall thickness you need. If you are applying tension or compression to pins in holes in the tubing, you could braze in hardened steel bushings. You would bore a larger hole in the tubing in which to insert the bushing. Bushings would distribute the force over a significantly larger surface area and the holes will not tend to elongate.

- Q: Is there any noticable or perceived difference between smoking out of a pipe with a brass screen and a stainless steel screen?

- Stainless Steel Pipe Screens

- Q: What are the common applications of galvanized steel coils?

- Galvanized steel coils are commonly used in various applications such as construction, automotive manufacturing, electrical appliances, and infrastructure projects. They are used for manufacturing roofing sheets, wall panels, pipes, gutters, and various structural components due to their corrosion resistance and durability. Additionally, galvanized steel coils are widely used in the production of automotive parts, such as body panels, frames, and chassis, as they provide excellent strength and protection against rust.

- Q: engineering sloutions related to steel fabrication

- not okorder /

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- There is a ludicrous mixture of the two at present. We export a large percentage of our steel to China predominantly but also to other regions then import what ever the shortfall is on the local market, often at inflated prices. The company I work for obtains all its steel from only one supplier, who we have shares in, and under the counter cash incentives are the order of the day, I keep myself above water by refusing the cash and sign no documents relating to those dealings, I'm not prepared to go to prison for a cash bonus.

- Q: is surgical steel or sterling silver belly button rings better for you? surgical is really cheap so its sketch and i justt dont want it to mess up

- Implant grade surgical steel is best. Surgical steel is not cheap. You must be looking at something else. And sterling silver shouldn't really be worn in piercings anyway. Have you ever cared for actual silverware or platters or anything? Notice the brownish film it gets on it? That's from oxidation....do you really want that to happen inside your piercing? That's bad news man.

Send your message to us

Hot Dipped Galvanized Steel Coil ASTM A653 JIS 3302 Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords