Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

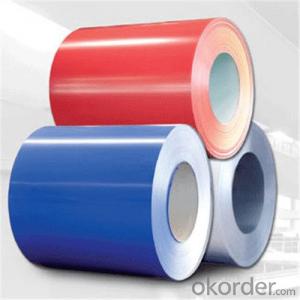

PPGI and PPGL

0.14-3.0mm Special Color Galvanized / galvalume Steel Coil

1. Techinical standard: EN10169

2. Grade: TDX51D, SGCC

3. Thickness: 0.14-3.0mm (the most advantage thickness)

4. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250)

5. Base metal: Galvanized / galvalume steel

6. Finish Painting: 15-20miu PE on top

Back painting: 5-8miu PE on back

7. Type of PPGI and PPGL with pattern

Specifications:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.14-3.0mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-275g or AZ 40-150g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

Why Us:

1, Mill/factory supply, Quality protection, 4 Galvanized steel lines keep runing.

2, Competitive price with best quality and service

3, Nearest sea port, Convenient transportation, Efficient service team online for 24 hours

4, More than 7 years Export Experiences, More than 50 countries customers

5. Delivery time: Within 25-35 days after the receipt of L/C or according to customer's requirement.

Warranty:

As the professional manufacturer and supplier of the steel, CNBM steel corporation makes the steel co-operation mutual beneficial without any risky to the worldwide customers. CNBM Steel sales&service department not only promise to provide the high quality products, excellent communication, fast and reliable deliveries, as well as the reasonble price, but also help the customers to develop the market better with more efforts.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

CNBM Steel has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc...

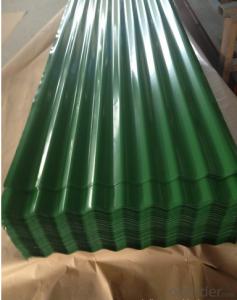

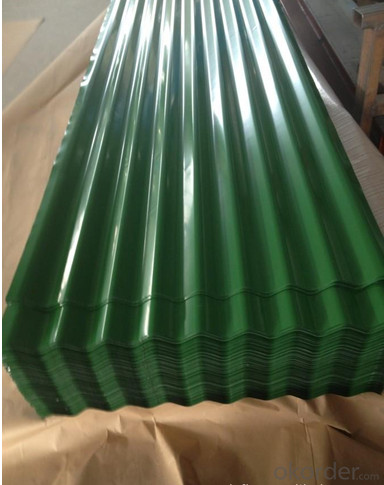

commodityColor-coated Roofing Galvanized Steel sheet

Techinical Standard: JIS G3302-1998, EN10142/10137, EN 10169

gradeSGCC, DX51D / DX52D / S250, 280GD

Types: For general / drawing use

Thickness0.14-3.0mm

Zinc Coating: 40g-275g or AZ 40-150g

Spanglet:No/ small/ big regular

Surface treament:Chromed passivation, anti-finger print, skinpassed

Sheet weight:3-5MT

Profile model: YX14-65-825/ YX18-76.2-836 / YX14-63.5-825 /

YX35-125-750 / YX15-225-900 / YX10-125-875 /

YX12-110-880 / YX25-210-840 / YX25-205-820(1025)

Package: Properly packed for ocean freight exportation in 20' ' containers

Application:Roof, walls, internal and external decorating materials, building etc

Price termsFOB, CFR, CIF

Payment terms20%TT in advance+80% TT or irrevocable 80%L/C at sight

delivery time25 days after recepit of 20% TT

RemarksInsurance is all risks

MTC 3.1 will be handed on with shipping documents

We accept SGS certificatation test

commodity | Brick pattern Color Galvanized Steel Sheet (PPGI/ PPGL) |

Techinical Standard: | JIS G3312-1998, EN101169, ASTM A755 |

grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

Types: | For general / drawing use |

Base metal | galvanized, galvalume |

Thickness | 0.14-3.0mm(0.16-0.8mm is the most advantage thickness) |

Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

Type of coating: | PE, SMP, PVDF |

Zinc coating | Z60-275g/m2 or AZ40-150g/m2 |

Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

Back painting: | 5-7 mic. EP |

Color: | According to RAL standard |

ID coil | 508mm / 610mm |

Coil weight: | 4--8MT |

Package: | Properly packed for ocean freight exportation in 20' ' containers |

Application: | Industrial panels, roofing and siding for painting / automobile |

Price terms | FOB, CFR, CIF |

Payment terms |

|

delivery time |

|

Remarks | Insurance is all risks |

MTC 3.1 will be handed on with shipping documents | |

We accept SGS certificatation test |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How are steel coils used in the production of storage shelves?

- Steel coils are a vital element in the manufacturing of storage shelves. Typically composed of carbon steel, these coils undergo various processes to achieve the desired form. To begin using steel coils for storage shelves, the coil must be unrolled and flattened. This operation is executed by a decoiler machine, which unwinds the coil and guides it through a series of rollers to flatten the metal. Once the coil is flattened, it is prepared for further processing. Following this, the flattened steel is cut into specific lengths using either a shearing machine or a saw. These cut pieces are then bent and shaped to fit the appropriate dimensions required for the storage shelves. The bending process is typically carried out using a press brake or a roll former, which applies pressure to the metal to achieve the desired shape. Once the steel has been shaped to the correct dimensions, it is welded together to form the structure of the storage shelf. This welding procedure guarantees the strength and durability of the shelves, enabling them to support heavy loads. Upon completion of the welding process, the storage shelves may undergo additional treatments to enhance their appearance and protect them against corrosion. These treatments can include processes like powder coating, galvanization, or painting. In summary, steel coils play an indispensable role in the production of storage shelves. They provide the essential raw material and their versatility allows for a wide range of shapes and sizes to be created. The strength and durability of steel make it the ideal choice for storage shelves, ensuring that they can endure heavy loads and provide long-lasting storage solutions.

- Q: What are the different types of steel coil surface treatments for indoor applications?

- There are several different types of steel coil surface treatments that are suitable for indoor applications. These treatments are designed to enhance the appearance, durability, and performance of the steel coil in various indoor environments. Some of the common surface treatments for indoor applications include: 1. Galvanized Coating: This is one of the most popular surface treatments for indoor applications. Galvanizing involves applying a layer of zinc to the steel coil, which provides excellent corrosion resistance and protects the steel from environmental elements. 2. Pre-painted Coating: Pre-painting the steel coil with a specific color or finish is another common surface treatment for indoor applications. This coating not only improves the aesthetics of the steel, but also provides additional protection against corrosion and wear. 3. Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the steel coil and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile choice for indoor applications. 4. Vinyl Coating: Vinyl coating is a type of surface treatment that involves applying a layer of PVC (polyvinyl chloride) to the steel coil. This coating provides excellent chemical resistance and protects the steel from moisture, abrasion, and UV radiation. Vinyl coating is commonly used in indoor applications where chemical exposure or moisture resistance is a concern. 5. Laminated Coating: Laminating the steel coil involves bonding a thin layer of plastic or other material to the surface of the steel. This treatment enhances the appearance of the steel and provides additional protection against scratches, stains, and fading. Laminated coatings are available in various colors and patterns, making them suitable for indoor applications where aesthetics is a priority. It is important to consider the specific requirements of the indoor application when choosing a steel coil surface treatment. Factors such as corrosion resistance, durability, aesthetics, and budget should be taken into account to ensure the best possible performance and longevity of the steel coil in indoor environments.

- Q: How are steel coils used in the production of steel cables?

- Steel coils are used in the production of steel cables as they serve as the raw material for cable manufacturing. The steel coils are unwound and then processed through a series of steps, such as drawing, stranding, and coating, to transform them into steel cables of various sizes and strengths. These cables are widely used in industries like construction, transportation, and telecommunications for purposes such as supporting structures, lifting heavy objects, and transmitting electrical signals.

- Q: I'm not sure.Alloy stainless steel 308 series.

- There are potential risks in some cookware materials. Aluminum and Teflon-lined pots, pans and bakeware are safest when kept in good condition and used properly. Mixing steel with chromium and nickel (18/8 stainless steel is 18% chromium and 8% nickel while 18/10 has 10% nickel) produces a corrosion resistant steel that is both hard wearing and easy to clean. Stainless steel cookware is considered one of the best and safest choices in cookware.

- Q: How hot does steel have to get before it will melt?

- Type your query into Yahoo! Search or other search engines to get the answer: It depends, since steel usually has different metals added for various properties (strength, corrosive resistance, etc.)

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- Quite a few companies make stainless steel cleaners. Don't use Windex, I was told when we bought our stainless fridge and stove. Go to Home Depot or a store like it and I am sure they will have some to choose from. I bought these pre-treated wipes for Stainless Steel at Bath Beyond (like Lysol makes) and they work wonders for a quick cleaning. Linens N Things also has some wipes.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut.

- Q: Monopolistic competition means all of their products are identical like things in supermarket like milk. There are no high barriers to entry. Oil and steel are all same in all industries.

- That okorder /

- Q: What are the different types of corrosion protection for steel coils?

- There are several different types of corrosion protection for steel coils, including galvanizing, paint coatings, organic coatings, and metallic coatings. Each method provides a barrier between the steel surface and the corrosive environment, preventing or slowing down the corrosion process. Galvanizing involves applying a layer of zinc to the steel surface, while paint coatings use various types of paints or primers. Organic coatings utilize polymers or resins to form a protective layer, and metallic coatings such as tin or aluminum can also be applied. The choice of corrosion protection method depends on factors such as the specific corrosive environment, desired lifespan, and cost considerations.

- Q: How are steel coils used in the manufacturing of doors and windows?

- Steel coils are used in the manufacturing of doors and windows by being processed into flat sheets or strips, which are then cut, shaped, and formed into various components such as frames, panels, and reinforcements. The steel coils provide strength, durability, and stability to the final products, ensuring high-quality doors and windows that can withstand different weather conditions and provide security to buildings.

Send your message to us

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Building

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords