All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are taken to ensure coil gauge consistency during the production of construction machinery and equipment?

To ensure coil gauge consistency during the production of construction machinery and equipment, several measures are taken. Firstly, stringent quality control procedures are implemented at each stage of the manufacturing process. This includes regular inspections and testing of the coils to ensure they meet the required gauge specifications.

Additionally, advanced technology and automated systems are employed to monitor and control the coil gauge during production. These systems use sensors and feedback mechanisms to provide real-time measurements and adjustments, ensuring the coils maintain consistent gauge throughout the manufacturing process.

Furthermore, proper training and qualification of the production personnel play a crucial role in maintaining coil gauge consistency. Skilled operators are trained to handle and process coils accurately, minimizing any deviations from the required gauge specifications.

Overall, a combination of quality control procedures, advanced technology, and trained personnel are key measures taken to ensure coil gauge consistency during the production of construction machinery and equipment.

What is the impact of coil temperature on the quality of laser-cut components?

The impact of coil temperature on the quality of laser-cut components is significant. Coil temperature directly affects the material's characteristics, such as its hardness, ductility, and thermal conductivity, which in turn influence the cutting process. If the coil temperature is too high, it can lead to excessive melting, irregular cuts, and rough edges. On the other hand, if the coil temperature is too low, it can result in cracking, brittleness, and poor cutting precision. Therefore, maintaining an optimal coil temperature is crucial for achieving high-quality laser-cut components.

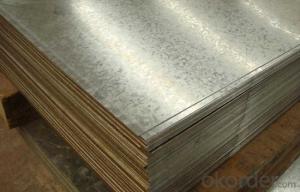

How are steel coils protected during overseas transportation?

Steel coils are typically protected during overseas transportation through a combination of secure packaging, proper handling, and the use of specialized shipping containers. This can include wrapping the coils with protective materials like plastic or paper, securing them with steel bands or straps, and placing them in sturdy containers. Additionally, these containers are often designed to withstand the rigors of long-distance transportation, ensuring that the steel coils remain safe and intact throughout the journey.

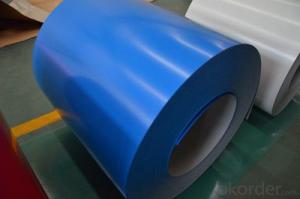

Wholesale Steel Coils from supplier in British

With our strong partnership with CNBM, we have access to a wide network of steel coil manufacturers, ensuring that we can offer competitive prices and a diverse range of high-quality products. Whether you require hot-rolled, cold-rolled, or galvanized steel coils, we have the expertise to meet your specific needs.

In addition to our sales and quotation services, we also provide technical support to assist you in selecting the right steel coils for your applications. Our team of experts is well-versed in the British market's requirements and can guide you in choosing the most suitable products for your projects.

We understand the importance of timely delivery, and we strive to ensure that your orders are delivered efficiently and on schedule. Our logistics team works closely with reliable shipping partners to guarantee the safe transportation of your steel coils to your desired location.

Customer satisfaction is at the core of our business, and we are committed to providing excellent service throughout the entire procurement process. Whether you are a small business or a large corporation, we are dedicated to meeting your steel coil needs and exceeding your expectations.

Contact us today to discuss your steel coil requirements and let us demonstrate how our expertise and comprehensive procurement services can benefit your business.

In addition to our sales and quotation services, we also provide technical support to assist you in selecting the right steel coils for your applications. Our team of experts is well-versed in the British market's requirements and can guide you in choosing the most suitable products for your projects.

We understand the importance of timely delivery, and we strive to ensure that your orders are delivered efficiently and on schedule. Our logistics team works closely with reliable shipping partners to guarantee the safe transportation of your steel coils to your desired location.

Customer satisfaction is at the core of our business, and we are committed to providing excellent service throughout the entire procurement process. Whether you are a small business or a large corporation, we are dedicated to meeting your steel coil needs and exceeding your expectations.

Contact us today to discuss your steel coil requirements and let us demonstrate how our expertise and comprehensive procurement services can benefit your business.