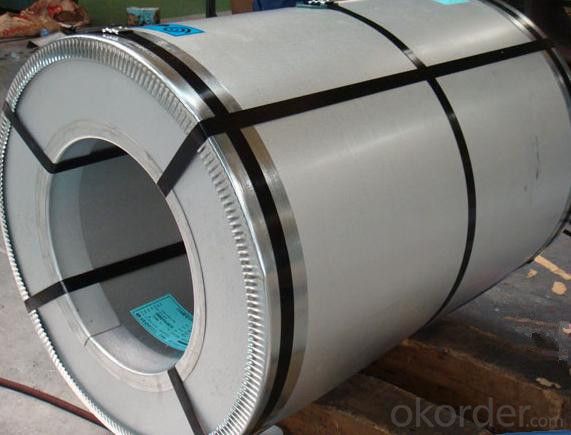

High Tensile Regular Spangle Galvanized Steel for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:SGCC, DX51D, ASTMA653

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:SGCC, Dx51d

Surface Treatment:Galvanized

Technique:Cold Rolled

Thickness:0.15-5.0mm

Width:914, 925, 1000, 1219, 1220, 1250, 1500

Zinc Coating:Z60-Z275, G30-G90

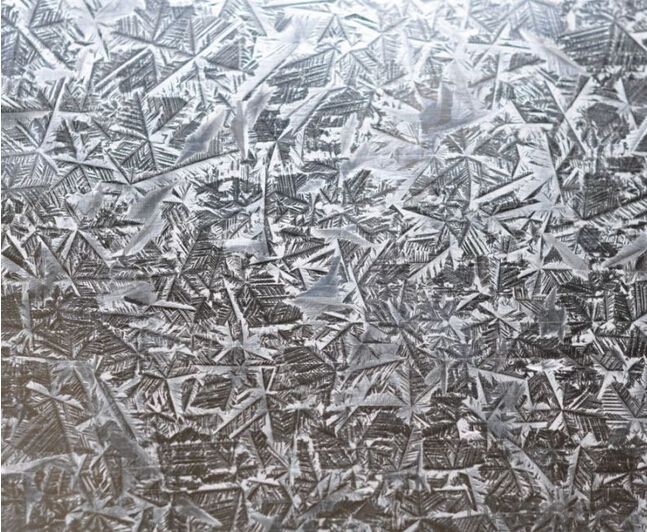

Surface:Regular Spangle, No-Spangle or Mini Spangle

Reference Standard:JIS G3302-1998, En10142-2000, GB/T2518-2004, ASTM

Export Markets:Global

Additional Info.

Packing:Export Standard

Standard:SGCC, DX51D, ASTMA653

Origin:China

HS Code:7210490000

Production Capacity:20000mt Per Month

Product Description

Products Key words:

galvanized steel, galvanized steel coil, galvanized steel sheet, gi, gi coil, gi sheet, hdgi, hot dip galvanized steel coil, galvanized sheet, gi sheet price, zinc sheets, galvanized sheet metal prices, zincked sheet, galvanized strip, price of zinc sheets, zinc strip sheet, galvanized sheet metal fence panel,corrugated galvanized steel sheet,galvanized roofing sheet

Material brand:

SGCC,DX51D,ASTMA653,commercial quality,cs type A,locking forming type,S250,S280GD,S350GD,G550,SGC400,SGC440,S250GD,S350GD,G550,SGH340,SGH440.

HDGI Manufacture

THICKNESS 0.15-5.0MM,WIDTH,914,925,1000,1219,1220,1250,1500, Galvanized steel coil, HDGI

Thick: 0.15 to 5.0mm

Reference standard: JIS G3302-1998, EN10142-2000, GB/T2518-2004, ASTM A653M

Zinc coating:Z60-Z275,G30-G90,

Regular Spangle, No-spangle or Mini Spangle

Coil diameter: ID 508mm 610mm

HDGI MECHANICAL SPECS:

JIS G3302Yield Point Minimum N/mm2Tensile Strength MinimumElongation Minimum %Application

Classified symbolN/mm2Nominal Thickness mm (t)

cold-rolled base metalhot-rolled base metal 0.25≤0.4≤0.6≤1.0≤1.6≤t≥2.5

t<0.4t<0.6t<1.0t<1.6t<2.5< span="">

SGCCSGHC205270------------------Commercial

SGCH---------------------------Commercial Hard

SGCD1------270---34363738---Drawing

SGC340SGH340245340202020202020Structural

SGC400SGH400295400181818181818Structural

SGC440SGH440335440181818181818Structural

SGC490SGH490365490161616161616Structural

---SGH540400540161616Structural

SGC570560570------------------Structural

Equal coating thickness:

Coating Weight Marking Code (Zinc)Z06Z08Z10Z12Z18Z20Z22Z25Z275

Coating Thickness0.0130.0170.0210.0260.0340.0400.0430.0490.054

Packaging Details:

Packing: Standard export packing, 4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal and waterproof paper wall protection disk, galvanized metal and waterproof paper around circumference and bore protection

Scope of Application:

Usage: construction,the manufacturing of cars, ships, containers and household electric appliances,other industries usage.

World wide customer satisfaction:

More than 50 worldwide customers none-risky experiences approved.

Yogic has been exporting steel coils to more than 50 countries directly. Our long term supply extends to USA, UK, Germany, Italy, Spain, Belgium, France, Poland, Greece, Ukraine, Belarus, Russia, Turkey, Egypt, Saudi Arabia, Iran, Ethiopia, Niger, Brazil, Colombia, Chile, Peru, Australia, New Zealand, etc

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils typically include various inspections and tests to ensure that the coils meet the required standards and specifications. These measures often involve visual inspections to identify any surface defects or irregularities, such as cracks, dents, or scratches. Additionally, dimensional checks are performed to verify the coil's size, shape, and weight. Other quality control measures may involve conducting mechanical tests, such as tensile strength and hardness tests, to assess the strength and durability of the steel coils. Overall, these measures aim to guarantee that the steel coils are of high quality and suitable for their intended applications.

- Q: if steel is heated from room temperature (20c) to (500c) what would be the change in density?coefficient for linear expansion of steel 12x10^-6 k density of steel 7800 kg

- First you have to convert the coefficient of linear expansion to a coefficient of volumetric expansion. Multiply the coefficient of linear expansion by 3: Coefficient of expansion of steel,β:12E-6/°K x 3 = 36E-6/°K Difference in temperature: 480°K ΔV = VoβΔT ΔV = Vo x (0.000036) x 480 ΔV = 1m? x 0.017 ΔV = 0.017m? Originally, the steel was at 7800 kg/m? Now, the steel was at 7800 kg/ 1.017m?, or 7670 kg/m? Change in density = 7670 - 7800 = -130kg/m?

- Q: I asked a question last week about stainless steel and got some great answers. I combed all over the internet to try to figure this one out but could not find anything. What resists bending better: chrome vanadium steel (i.e. a steel commonly used to make tools) or stainless steel 304. My guess would be the chrome vanadium alloy but thats just a guess. Which on resist's bending better and by how much (#'s please :-)). Also, if anyone knows if chrome vanadium steel is cheaper than stainless steel 304 that would be awesome? I can't find a price per pound on chrome vanadium steel anywhere! Please help. Thanks in advance-Josh

- Fill the pot up w/cold water to cover the burned on rice. Bring it up to a boil. Do it again w/some high powered soap in the mix. This time let the water sit in the pan until its luke warm, dump it out and scrub it up w/the plastic scouring pad. You should be all set.

- Q: How are steel coils inspected for surface cleanliness during processing?

- Steel coils are inspected for surface cleanliness during processing through various methods such as visual inspection, magnetic particle inspection, and ultrasonic testing. These techniques help identify any contaminants, defects, or surface irregularities that may be present on the coils, ensuring their quality and suitability for further processing or use.

- Q: im buying a sword and i dont know if i should buy a cold steel sword or a normal sword and that i can some how make that cold steel

- What Is Cold Steel

- Q: How do steel coils contribute to sustainability in construction?

- Steel coils contribute to sustainability in construction in several ways. Firstly, steel is a highly durable material that has a long lifespan. Steel coils are used in the construction of various structural components like beams, columns, and frames, ensuring the stability and strength of buildings. By using steel coils, the resulting structures require less maintenance and have a longer service life, reducing the need for frequent repairs or replacements. This durability enhances the sustainability of construction projects by reducing the overall environmental impact associated with material waste and energy consumption. Secondly, steel is a highly recyclable material. Steel coils can be easily recycled and reused in new construction projects. The recycling process of steel has a significantly lower environmental impact compared to the production of new steel. Recycling steel coils helps to conserve natural resources, reduce the extraction of raw materials, and minimize energy consumption in steel production. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Furthermore, steel is a material that can be prefabricated off-site. This means that steel coils can be manufactured in factories in a controlled environment, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces the amount of material waste generated on-site and decreases the need for transportation of construction materials, thereby reducing air pollution and energy consumption during construction. Additionally, steel is known for its high strength-to-weight ratio, which allows for lighter and more efficient structures. By using steel coils, construction projects can optimize the use of materials, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to sustainability in construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: I have two theories, which one's correct?My book says that steel is made up of 98% iron and 2% carbon.98% of iron's molar mass (55.85 g/mol) is 54.733.2% of carbon's molar mass (12.01 g/mol) is .2402.If you add them up that gives you that steel has a molar mass of 54.97 g/mol.However, steel's chemical formula is Fe(3)CThat would make it's molar mass 179.56 g/mol.( Because 3(55.85) + 12.01 = 179.56 )Which one is correct?

- Molar Mass Steel

- Q: What are the common methods of inspecting steel coils for defects?

- Inspecting steel coils for defects involves several commonly used methods. These methods encompass visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing. Visual inspection, the most basic method, entails physically examining the steel coil's surface for noticeable defects like cracks, dents, or irregularities. Typically, this initial step in the inspection process promptly identifies any obvious defects. Ultrasonic testing, a more advanced method, employs high-frequency sound waves to detect defects within the steel coil. Ultrasonic waves are transmitted into the coil via a probe, and any internal flaws or defects reflect the waves back to the probe. This method effectively identifies defects such as voids, cracks, or inclusions. Magnetic particle inspection is another commonly utilized method. It involves magnetizing the coil and applying iron particles to the surface. Defects or cracks disrupt the magnetic field, attracting the iron particles and making them visible. This method is particularly effective for surface cracks or defects. Eddy current testing is a non-destructive method utilizing electromagnetic induction to detect defects in the steel coil. By generating an alternating magnetic field using a probe, any changes in the material's electrical conductivity or magnetic permeability due to defects generate eddy currents. These eddy currents can be measured and analyzed to identify defects like cracks, voids, or changes in material properties. In summary, these common methods offer varying levels of accuracy and sensitivity in inspecting steel coils for defects, ensuring their quality and integrity. The choice of method depends on factors such as the type and size of defects to be detected, the required level of inspection accuracy, and the time and cost limitations of the inspection process.

- Q: Not sure if stainless steel is actually sealable but what's the best way to clean a brushed stainless steel appliance to not get so many finger prints...etc. I have stainless steel wipes that I used on another appliance and they don't work so great.

- Straight white vinegar on a clean white cloth does an amazing job on all my appliances. Makes the kitchen smell great to.

- Q: How are steel coils used in the manufacturing of appliances?

- Steel coils are used in the manufacturing of appliances as a primary material for constructing the appliance's body or frame. The coils are shaped and molded to form the necessary components, providing strength, durability, and stability to the appliance.

Send your message to us

High Tensile Regular Spangle Galvanized Steel for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords