High Temperature Fiberglass Fabric Coated with Vermiculite

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: Vermiculite coated fiberglass fabrics is mainly composed of alkali-free glass fiber and vermiculite, in which glass fiber is the substrate and vermiculite is the coating material. Vermiculite is a natural mineral. The vermiculite coating makes the composite glass fiber cloth resistant to high temperature in a short time to 1000℃ and continuous temperature resistance to 800℃.In the production process, the vermiculite is uniformly coated on the fiberglass products, and then dried in the subsequent process, the vermiculite settles on the fiberglass products, so as to produce coated vermiculite glass of different thicknesses and specifications Fiber products. At the same time, the glass fiber cloth has stronger fire breakdown resistance and friction resistance, and good mechanical processing performance.

Features: High Temperatures And Abrasion Resistant, Heat Protection

Application: high temperature gloves, high-temperature gaskets, and other high-temperature personal protective equipment, insulation blankets, welding blankets, welding pads, thermal protection, high temperature lagging, high temperature sealing, fire curtains, thermal insulation curtain, expansion joints

PRICE: USD7 per square meter

UNIT: square meter

MOQ: 500 square meters

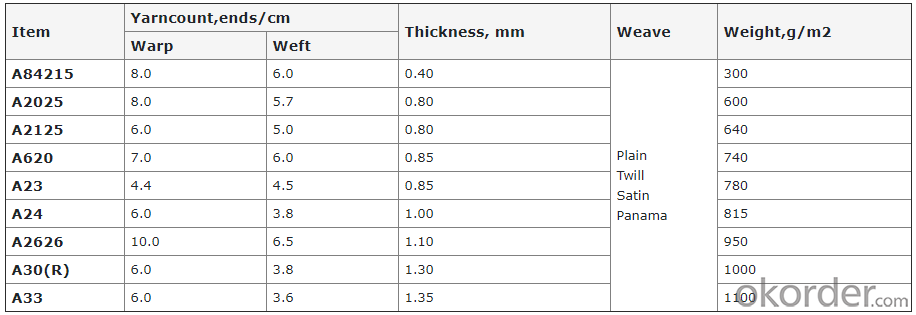

Weight: 600gsm-3000gsm or customized

Width: 0.9m-2m or customized

Yarn Type: E-glass

Standing temperature: 850℃-1000℃

Product name: Vermiculite coated fiberglass fabric

Coating/Finish/Surface Treatment: Vermiculite coated

Roll length: 50 meter or customized

Color: Yellow

Weave Type: plain woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass fabric, Vermiculite

Thickness: 0.6mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Vermiculite coated fiberglass fabrics rolls covered with film packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to electrical conductivity?

- Yes, fiberglass fabric is resistant to electrical conductivity. Fiberglass is made from woven fibers of glass, which are non-conductive materials. This means that fiberglass fabric does not allow the flow of electrical current through it. It is commonly used in electrical insulation applications as it provides a protective barrier against electrical shocks and is an excellent insulator. The non-conductive nature of fiberglass fabric makes it a suitable choice for various electrical and electronic applications where the prevention of electrical conductivity is required.

- Q: Can fiberglass fabric be used for making filters for air purifiers?

- Yes, fiberglass fabric can be used for making filters for air purifiers. Fiberglass fabric is known for its excellent filtration properties, making it an ideal material for capturing and trapping airborne particles such as dust, pollen, pet dander, and other allergens. It can effectively remove these contaminants from the air, improving indoor air quality and promoting a healthier living environment. Additionally, fiberglass fabric is durable and resistant to high temperatures, making it suitable for long-term use in air purifiers. However, it is important to note that fiberglass can release tiny particles when damaged or mishandled, which can be harmful if inhaled. Therefore, it is crucial to handle and maintain fiberglass filters with care to prevent any potential health risks.

- Q: Can fiberglass fabrics be used for clothing or fashion purposes?

- Yes, fiberglass fabrics can be used for clothing or fashion purposes. However, they are less commonly used due to their properties like being non-breathable, stiff, and potentially irritating to the skin.

- Q: Are fiberglass fabrics resistant to mold or mildew?

- Yes, fiberglass fabrics are generally resistant to mold or mildew due to their non-porous nature and lack of organic materials that promote mold growth.

- Q: Can fiberglass fabric be used for making insulation boards?

- Indeed, insulation boards can be crafted using fiberglass fabric. This fabric is widely utilized in the production of insulation boards owing to its exceptional heat properties and fire resistance. Comprised of delicate glass strands, the fabric is skillfully interwoven to yield a resilient and adaptable material. By layering or compressing this fabric, the desired thickness and R-value, which gauges the insulation's ability to impede heat transfer, can be achieved. Moreover, fiberglass fabric exhibits resistance to moisture and actively discourages the growth of mold or mildew. In summary, the durability, thermal efficiency, and safety attributes of fiberglass fabric render it a favored option for insulation boards.

- Q: What type of thread is used for sewing fiberglass fabric?

- The type of thread typically used for sewing fiberglass fabric is a polyester thread.

- Q: Can fiberglass fabrics be used for reinforcement in boats or yachts?

- Yes, fiberglass fabrics are commonly used for reinforcement in boats or yachts due to their high strength-to-weight ratio, excellent durability, and resistance to water and corrosion. Their flexibility and ability to conform to complex shapes make them ideal for reinforcing various parts of boats and yachts, such as hulls, decks, and bulkheads.

- Q: Can fiberglass fabric be used for insulation tapes?

- Yes, fiberglass fabric can be used for insulation tapes. Fiberglass fabric is known for its excellent thermal insulation properties, making it an ideal material for insulation tapes. It can effectively prevent heat transfer and provide insulation for various applications, such as electrical, HVAC, and industrial insulation. In addition, fiberglass fabric is also resistant to fire, chemicals, and moisture, making it a durable and reliable option for insulation tapes.

- Q: How does fiberglass fabric perform in high-pressure applications?

- Fiberglass fabric excels in high-pressure applications due to its exceptional performance. Its inherent strength and durability allow it to withstand high levels of pressure without compromising its structural integrity. The tightly woven fibers of fiberglass fabric provide excellent resistance to stretching, tearing, and bursting, making it a perfect choice for high-pressure environments. One of the major advantages of fiberglass fabric in high-pressure applications is its ability to maintain dimensional stability, even under extreme pressure. Unlike other materials that may deform or lose their shape, fiberglass fabric retains its form and strength, ensuring consistent performance over time. This stability is crucial in industries like aerospace, oil and gas, and automotive, where high-pressure conditions are prevalent. Furthermore, fiberglass fabric exhibits high chemical resistance, making it suitable for applications involving exposure to corrosive substances or harsh environments. It can withstand the effects of various chemicals, acids, solvents, and even extreme temperatures, ensuring its longevity and reliability in high-pressure settings. Additionally, fiberglass fabric offers excellent thermal insulation properties, which can be advantageous in high-pressure applications where temperature control is vital. It effectively resists heat transfer, preventing energy loss and maintaining the desired temperature within the system. In conclusion, fiberglass fabric excels in high-pressure applications due to its strength, dimensional stability, chemical resistance, and thermal insulation properties. Its ability to withstand high levels of pressure without compromising its structure makes it an ideal choice for industries operating in demanding environments.

- Q: Can I put up wall tiles on the bathroom wall waterproof cloth?

- Water repellent. By mixing cement mortar waterproof agent in the kitchen or bathroom at the grassroots level to do it again, after the dry, use waterproof admixture cement ash in the first layer on the brush layer, which is mainly for the first time will be generated through the dry hole blocked after, there is the root of the pipeline should be carefully brush.

Send your message to us

High Temperature Fiberglass Fabric Coated with Vermiculite

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords