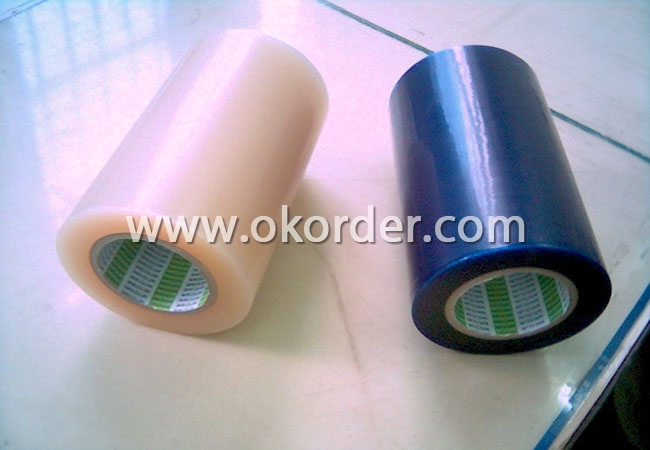

High Quality PE Protective Film White Color S60-30W

- Loading Port:

- China Main Port

- Payment Terms:

- TT Or LC

- Min Order Qty:

- 10000 Square Meters m²

- Supply Capability:

- 10000 square meter per month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Application: Mirror finish stainless steel need sophisticated protection. Usually 2layers white color PE protective film are used, with inner one S60-30W and outer layer a little sticky S100-30W. So that the steel is well protected from dirt and scratch during production, transportation and installation.

2. White color and transparent color are popular for mirror finish stainless steel surface protection. Transparent blue color, black & white color, red color and so on available as per customers' requirements.

3. The choice of surface protective film depends on the surface: material and roughness. Tell us what surface you want to protect and we will recommend proper film to you.

Technical Data of High Quality White Color PE Protective Film S60-30WItem Number: S60-30W (first layer); S100-30W (second layer)

Carrier: PE (polyethylene) film

Thickness: 30micron (0.03mm)

Peel Adhesion: 60g/25mm; 100g/25mm

Adhesive: solvent acrylic

Color: white

Temperature Resistance: 60C 48hours no residue

Elongation: ≥250%

Inner Diameter: 3" (76mm)

Length: within 3000meter

Widh: within 1.5meter

Recommended jumbo roll size: 1.0m x 1000m

Packing of High Quality White Color PE Protective Film S60-30W

Wrapped with kraft paper or carton.

Remarks of High Quality White Color PE Protective Film S60-30W

A. The data above are typical results and subject to change without notice.

B. Tolerance: 5%

C. The products should be stored at room temperature and be kept away wet and/or heat source.

D. It is essential, the surface of film must be clean, dry, and free of grease and oil.

E. The users should take test and do trial-application on the above product before coming into application so as to witness and ensure suitability for their special purpose and technique

- Q: What material is used for the adhesive film of the protective film on the aluminum plate?

- The protective film on the aluminium plate is made of PE thin film. Specifically, the film is co-extruded by three layers of thin film. The film can be sticked to the aluminium plate to protect the surface of the aluminium plate from unexpected scratches and damage after it's covered with glue. If you want to learn more about PE protective film, you can go to the PP forum. There are many insiders who are specialized in this field.

- Q: What kinds of materials is the protective film made from?

- According to material quality, it can be made from common materials including PET, OPP (PP), PVC and PE.

- Q: The protective film is not just to buy a reverse beat back, transparent paper pasted on the racket above, it is how to use?? Is it one-off or multiple?

- The general need to purchase another reverse protection film, which is a soft rubber protective film attached to the above, can maintain the racket surface friction, protective film surface, prolong the service life of the racket, and can be used repeatedly.

- Q: How to remove the protective films on ceramic tiles?

- There are three types of protective film used on ceramic tiles: The first one is plastic thin film which can be slowly torn by hands or gently rubbed off with steel wool; The second is anti-fouling protective film which can be wipe off using towel with white cement; The third is wax protective film which can be wipe off with dry towel with electric diluent, lacquer thinner, talcum powder or white cement.

- Q: How do you keep the film on the refrigerator for a long time?

- Then, blow it with the blower for 2 minutes, then put the new adhesive tape on it and blow it back and forth

- Q: How many kinds of material are there in the decoration ground protection film?

- PE is the most kind of protective film, divided into PE film, PE electrostatic membrane, PE mesh film, PE stretch film, PE packaging film, viscosity from 5g-270g, thickness from 1.5C-15C. The most commonly used is 5C.PET protective film has silica gel PET, acrylic adhesive PET, frosted PET, three layer PET, single layer PET, double layer PET, PET release film. PET protective film is usually used as screen protection, and PET film is often used for die stamping of PET protective film in die cutting factory. The most commonly used punching dies are 5C and 7.5C. The commonly used parting films are 2.5C, 3.8C, 5C and 7.5C.

- Q: Mobile phone protection film paste, and then ripped off, but also paste it? How should I post it?

- 3, in the paste at the same time, to side film, while pressing, remove the veneer under the air, while pushing. Carefully remove the air, so as not to leave the bubble, affecting the appearance.4, after the paste, you can tear off the top layer of "off form film".

- Q: Is it good to stick a protective film on a laptop or not?

- We know that the LCD protective film factory configuration is a layer of plastic film, and the film, not only greatly affect the visual effects, reduce the permeability and have a lot of reflection, will affect the user's eye. In addition, the heat dissipation of the display is extremely unfavorable. The plastic film is not a good conductor of heat. The liquid crystal panel will heat up after a period of time, and touch the panel with the back of the hand. You can tell that the temperature is very high. If the surface is coated with a protective film with poor thermal conductivity, it virtually prevents the cooling of the liquid crystal and even shortens the effective life of the display.

- Q: PVC protective film and weaved cloth, which is better to protect floor?

- You'd better use cotton PVC film. But it's expensive. Using ordinary gypsum board is also okay. You can cover the edges of the board with tape.Its cost performance is high. And it's really durable.

- Q: Generally, what kind of film is used to cover glass?

- It's perhaps anti-sunlight film.

1. Manufacturer Overview

| Location | Dongguan, China |

| Year Established | 2011 |

| Annual Output Value | US$ 10 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen Port |

| Export Percentage | 10% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 30,000 square meters |

| No. of Production Lines | Above 1 |

| Contract Manufacturing | film |

| Product Price Range | High; Average |

Send your message to us

High Quality PE Protective Film White Color S60-30W

- Loading Port:

- China Main Port

- Payment Terms:

- TT Or LC

- Min Order Qty:

- 10000 Square Meters m²

- Supply Capability:

- 10000 square meter per month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords