High Quality Cold Drawn Laserable Aluminum Sheets Gold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Cold Drawn Aluminum Alloy Plate Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Cold Drawn Aluminum Alloy Plate :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

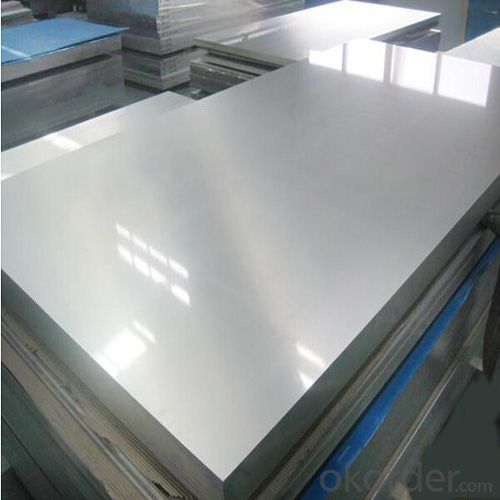

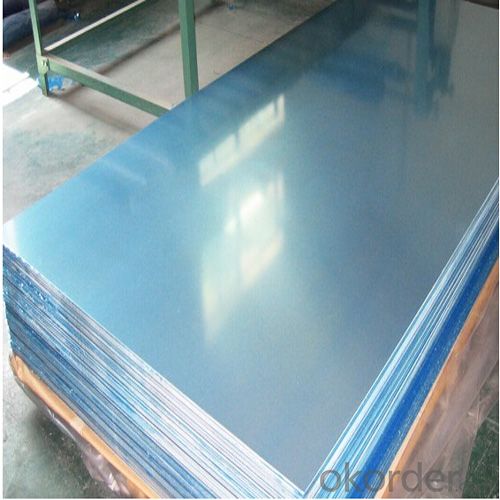

3. Cold Drawn Aluminum Alloy Plate Images:

4. Cold Drawn Aluminum Alloy Plate Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Using thin copper sheets and thin aluminum sheets, respectively, from heat source heat conduction to aluminum heat sink, which kind of efficiency is higher?

- The key is not copper or aluminum, the heat transfer coefficient between the heat source and the heat sink is more important to the overall heat dissipation effect.In theory, copper is good, but copper is relatively expensive and heat dissipation is a little too high.

- Q: How do I choose the right thickness for my aluminum sheet?

- When deciding on the appropriate thickness for your aluminum sheet, there are several factors that should be taken into account. To begin with, it is essential to determine the intended use or purpose of the aluminum sheet. Different projects may necessitate varying thicknesses depending on their structural or aesthetic requirements. For example, if the aluminum sheets are intended for roofing or siding applications, a thicker gauge may be necessary to ensure sufficient durability and resistance to weather conditions. Moreover, the level of strength and rigidity required should be considered. Thicker aluminum sheets generally offer greater strength and stability, which is especially important for applications like construction or automotive components. However, it is important to bear in mind that thicker sheets may also be heavier and more challenging to work with, so the practicality and weight limitations of your project should be taken into consideration. Additionally, the size of the aluminum sheet needed should be thought about. Larger sheets may require thicker gauges in order to maintain their structural integrity, whereas smaller sheets may not require as much thickness. Lastly, your budget should be factored in. Thicker aluminum sheets can be more expensive due to increased material costs and the manufacturing process. It is advisable to strike a balance between the required thickness and your budget constraints to ensure a cost-effective decision. To summarize, selecting the appropriate thickness for your aluminum sheet involves considering the specific application, required strength, size, and budget. It is recommended to seek guidance and advice from industry experts or suppliers who can provide tailored recommendations based on your specific needs.

- Q: What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is approximately 23.1 x 10^-6 per degree Celsius.

- Q: How do aluminum sheets perform in terms of thermal insulation?

- Aluminum sheets are not effective in terms of thermal insulation. Due to their high thermal conductivity, aluminum sheets allow heat to easily transfer through them. This means that they are not able to effectively block or resist the transfer of heat, resulting in poor thermal insulation properties. If thermal insulation is the primary concern, other materials such as fiberglass, foam, or mineral wool would be more suitable choices.

- Q: are there any hazards in aluminium?

- The metal, yes. But you can always face the risk of get cut if it has sharp edges.

- Q: Where does China make aluminum plate?

- In many parts of the country have aluminum factory, the old state-owned enterprises have 101, SWA aluminum plant, located in the southwest, northeast china. The emerging aluminum processing base in Henan, due to resource advantages, the largest aluminum factory, the price is relatively low.

- Q: I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- Because of the aluminum chemical properties. Aluminum Oxide (Al2O3) is an extremely hard and compact material, so when the metal is exposed, it gets a very thin coat of Al2O3 that has a 9 hardness (only diamond is harder), that protects the rest of the metal from the atmosphere. Also, you should question if the phosphoric acid actually attacks aluminum, that is because that acid is found in Pepsi and coke..., BUT, as far as i know cans have a little plastic coat inside..., so the liquid does not get in touch with the aluminum.

- Q: For example, in hydrangeas, when aluminum reacts with the anthocyanins in the flower's petals, the hydrangeas turn blue, but what chemical reaction occurs?

- Two factors affect the color in Hydrangea macrophylla cultivars: soil acidity and the presence of aluminium in the soil. To obtain a blue hydrangea, aluminum must be present in the soil. The pH of the soil should be low (4 - 4.5). In alkaline soil aluminium is tied up. The plants are unable to absorb the existing aluminium and the flowers will not bloom blue. Also, when aluminium in the soil is used up the flower color will be red or pink again. If the soil is watered with aluminium salts aluminium is accumulated in the petals and the color turns blue. Only red and pink colored Hortensis are suitable for the breeding of blue flowers. They contain the dye component delphinidin. At the end of this site you find explanation and the formula: www.uni-regensburg.de/Fakultaeten...

- Q: Do the aluminum sheets come with a protective coating?

- Indeed, the aluminum sheets are accompanied by a protective coating, which is skillfully applied in order to safeguard against any potential scratches, corrosion, or other forms of damage that may occur during the process of transportation and handling. This meticulous coating process guarantees that the aluminum sheets are delivered to our cherished customers in an immaculate state.

- Q: Are 101 aluminum sheets suitable for solar panel frames?

- Yes, 101 aluminum sheets are generally suitable for solar panel frames due to their high strength-to-weight ratio, corrosion resistance, and ease of fabrication.

Send your message to us

High Quality Cold Drawn Laserable Aluminum Sheets Gold

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords