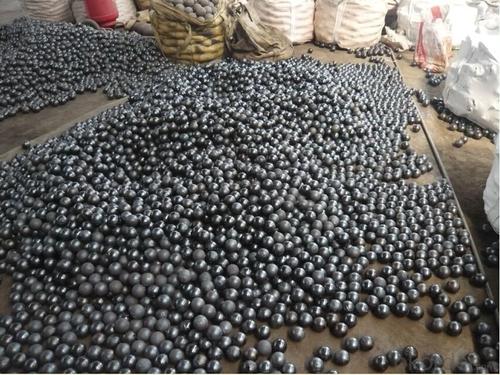

High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

1. Chemical Composition of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

Item | C | Cr | Si | Mn | S | P | Cu | Mo | Hardness |

Low Chrome | 1.8-3.5 | 1-3.5 | ≤1.2 | ≤1.5 | ≤0.15 | ≤0.15 | ≤0.5 | ≤1.0 | ≥45 |

Medium Chrome | 1.8-3.3 | 4-9 | ≤1.2 | ≤1.8 | ≤0.15 | ≤0.15 | ≤1.0 | ≤1.5 | ≥50 |

High Chrome | 1.6-3.3 | 10-15 | ≤1.0 | ≤2.5 | ≤0.10 | ≤0.10 | ≤1.5 | ≤1.0 | ≥55 |

Higher Chrome | 1.6-3.3 | 15-18 18-27 | ≤1.0 | ≤2.5 | ≤0.10 | ≤0.10 | ≤1.5 | <2.0 | ≥60 |

2. Weight and Quantity of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

No. | Diameter (mm) | Weight of each (kg) | Pcs/ton |

1 | Ø10 | 0.0135 | 74073 |

2 | Ø12 | 0.0181 | 55248 |

3 | Ø15 | 0.0242 | 41322 |

4 | Ø20 | 0.0322 | 31056 |

5 | Ø25 | 0.063 | 15873 |

6 | Ø30 | 0.11 | 9091 |

7 | Ø40 | 0.257 | 3891 |

8 | Ø50 | 0.50 | 2000 |

9 | Ø60 | 0.867 | 1153 |

10 | Ø70 | 1.37 | 729 |

11 | Ø80 | 2.05 | 487 |

12 | Ø90 | 2.90 | 345 |

13 | Ø100 | 4.00 | 250 |

14 | Ø110 | 5.30 | 188 |

15 | Ø120 | 6.80 | 147 |

16 | Ø125 | 7.75 | 129 |

17 | Ø130 | 8.74 | 114 |

3. Mechanical Properties of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (3.5m) | ||

Low Chromium | ≥45 | ≥8000 | P+C |

Medium Chromium | ≥50 | ≥12000 | P+C |

High Chromium | ≥55 | ≥15000 | M+C |

Higher Chromium | ≥60 | ≥22000 | M+C |

4. Production Process of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

Raw material(waste steel,waste iron,iron alloy)factory inspection→blending→melt→composition inspection→casting→cooling and solidification→demould→clean and polish→inspection→quenching(increase hardness)→hardness inspection→tempering(eliminate stress)→inspection→warehousing

5. Features of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

1) High hardness and resistance

2) Good even wear

3) No breaking

6. Applied Fields of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

1) Mining

2) Cement plants

3) Power stations

4) Chemical industry and machinery

7. Packing Methods of High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- 1, gray cast iron: General graphite annealing, to be heat treatment annealing, surface hardening etc.; ductile iron can be various: annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical heat treatment.2. Pouring liquid metal into the casting cavity which adapts to the shape of parts. After cooling and solidification, the casting method is called casting. Castings obtained by casting are called castings. Casting structure design: ensure the working performance and mechanical performance requirements, consider the technical requirements and performance of alloy casting casting casting structure, casting structure design is reasonable or not, the casting quality, productivity and cost has a great influence.3. Heat treatment is a metal hot working process in which the material is in solid state by means of heating, heat preservation and cooling to obtain desired microstructure and properties

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: What are the casting parts processing engineering?

- At present, casting processing, according to metal classification, divided into cast iron, cast steel, casting non-ferrous metal.

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found. The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

High & Low Chrome Alloyed Casting Grinding Ball with Dia0.75’’-Dia0.6’’(ISO9001:2008)

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords