Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

1. Introduction of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Grinding Ball as a medium for grinding machine, is consumables. Its main application is grinding materials to the usage standard. It is widely used in metal mines, power station, cement plant, chemical industry, etc.

2. Specification of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Size: 15-150mm

Hardness: 55-65HRC

Breakage Rate<0.5%

Impact Toughness>12J/CM2

Endurance Test>20000times

3. Chemical Composition of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Material | C | Mn | Si | Cr | S | P | V |

45# | 0.42-0.50 | 0.50-0.80 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

60Mn | 0.57-0.65 | 0.7-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

65Mn | 0.60-0.70 | 0.9-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 | |

B2 | 0.7-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 | |

75SiMn | 0.7-0.90 | 0.7-1.2 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 | |

Wear-resistant alloy | 0.5-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 | 0.1-0.2 |

4. Diametrical Tolerance and Weight of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

Nominal diameter (mm) | Diametrical tolerance (mm) | Weight of Single of grinding ball in average | Number of piece of One ton grinding ball in average |

DIA 20 DIA 25 DIA 30 DIA 40 DIA 50 |

+2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1949 |

DIA 60 DIA 70 DIA 80 DIA 90 DIA 100 |

+3 -2 | 888 1410 2104 2996 4110

| 1126 709 475 333 243 |

DIA 110 DIA 120 DIA 130 | +4 -2 | 5457 7102 9030 | 182 140 110 |

DIA 140 DIA 150 | +4 -3 | 11278 13871 | 88 72 |

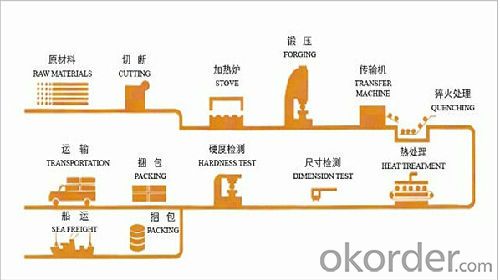

5. Production Process of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

6. Testing Methods of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

7. Packing Methods of Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

- Q: What are the casting parts used to test shrinkage holes?

- 3 fluorescent magnetic powder, this method can also be found in part.

- Q: What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: What kind of flaw detector is better for casting parts?

- If the casting is very small, can be used for fixed magnetic detection machines, of course with fixed magnetic powder the testing machine, the best first contact the manufacturers, because the fixed magnetic particle testing machine belongs to the non-standard equipment, according to the workpiece size, different shape, manufacturing daily inspection and measurement.

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Forged Steel Grinding Ball with High Hardness HRC60-HRC65 & Dia0.75’’-Dia6’’ & ISO9001:2008

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords