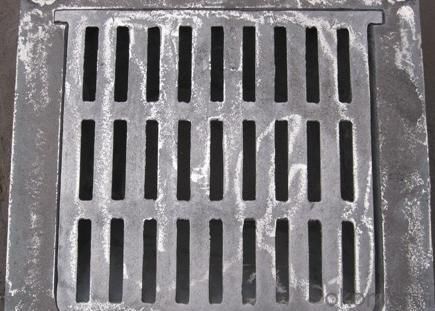

Ductile Iron Gully Grates Class D400

- Loading Port:

- TIANJIN

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 4000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specification of Ductile Gully Grates D400:

Class D400: EN124

The access covers and grates of this class are capable of withstanding a 400KN(-40 tonnes) test load

Use:

carriage ways, hard shoulders and pedestrian areas where cars and lorries have access.

Features of Ductile Gully Grates D400:

1. High load rating and strength

v Similar hard property as cast iron, while have a overwhelming advantage on stretch recovery.

v Less noise and lower vibration transmissions.

2. Against theft and safety options

v Zero theft value, reducing potential accident and further maintenance cost caused by thieves.

v Surface anti-slip thread guarantees safe road condition even in extreme weather.

v Locks are available as an option molded into the cover to improve security rate.

v Non-electricity conduction and non-heat conduction.

3. Lightweight

v Compared with cast iron manhole covers, composited covers are 50% lighter.

v Lightweight allows more loading per vehicle, more convenient transportation and economical saving.

v Allows a safer working condition, which a SINGLE worker is enough when installation without risk of injury.

4. Durable service life.

v More than 30 years service life without crack and color fading, comparing to 5 years of cast iron.

v Anti corrosion,water, dust and pets tight, well sealed prevent poisonous gas leaking out.

v Without displacement, freely radio signal passing.

v Higher and lower temperature tolerance with the range -40°C-200°C.

v Wear indicators available when thread depth is in a danger value.

5. Free design

v Much more clear resolution ratio of surface design than cast iron or BMC.

6. Carbon footprint saving and environmental care.

v Lower embedded energy carbon emission and during manufacturing process than cast iron covers.

Packaging:

Metal band, plastic, wooden pallet. As per customers' requirements

- Q: What's the effect of casting copper?

- Copper is one of the main corrosion resistant alloys. When the mass fraction of copper in cast iron is from 0.25% to 1%, the corrosion resistance of copper in the industrial atmosphere can be obviously increased. But copper has very little corrosion resistance in lye or salt solution.Copper can increase the flowability of molten iron and improve its casting ability remarkably.Copper can increase the coercive force and residual magnetic force, but the permeability is not affected.Combined use of copper with other alloy elements, such as copper chromium, copper chromium molybdenum, copper molybdenum, copper manganese, copper vanadium, can achieve greater results.

- Q: What are the requirements for casting steel castings?

- 1, high quality requirements of the surface or the main processing surface should be placed below.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Why do cheap cars like stamping parts instead of casting parts?

- The difference between automobile stamping parts and castingsAs the saying goes, there will be progress in comparison. In fact, through comparison, we can find the advantages and disadvantages of both. Next, we will talk about the difference between car stamping parts and castings.Looking for national casting orders, ductile iron castings, purchasing castings, foundry orders, and consulting foundry technology issuesCasting order networkAutomotive stamping parts are widely used in every field of our life, including some electronic components, auto parts, decorative materials and so on.

- Q: Is the cast steel a casting part?

- Cast steel is one of the casting parts that you call. The material is made of carbon steel or alloy steel, stainless steel, etc. the method is cast

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: The cause of fracture and why there is no toughness

- This question is too broad, see what the casting casting Oh in order to reduce the wayward cast steel, ductile iron, gray iron and white iron, you can choose the material according to their own requirements.

- Q: What is the casting material?

- Kdl1588n said in detail, casting a lot of material, steel, iron, aluminum, copper, zinc, etc. can be, valuable, as well as gold and silver, the most common on cast steel and cast iron, cast aluminum and so on.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- Tangshan Yongding automobile spare parts factory also give a lot of supply, casting factory of Tangshan n to the car enterprises casting wheel gearbox etc.The team of casting experts welcome you to ask questions and accept questions!

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 1.5 Million |

| Main Markets | Mid East, Africa, Europe |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 60% |

| No.of Employees in Trade Department | 300 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 15,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ductile Iron Gully Grates Class D400

- Loading Port:

- TIANJIN

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 4000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords