HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

1. Product Performance for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

a).Hardness:50-65

b).Chromium percentage:0.25MAX

c).Heat treatment:cycles

d).Impact test>12AK.J/CM2

e).Endurance test times>=10000

f).Characteristic: a)unbreakable; b)even hardness; c)high impact value; d)good wear resistance; e) high combined efficiency of grinding mill

g).Productive technology: forging /hot-rolling

h).Packing:container bag:1000Kgs/Container Bag, Steel Drums: 850-900Kgs/Drum

i).Application : a) Mines b) Cement plants; c) Power stations; d) Chemical industry; e) other grinding industries.

j).Certificates: SGS/TUV/ ISO9001:2008

k). Microstructure: M+B+C(M-Martensite;B-Bainitic;C-Carbide)

2. Chemical Composition for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

Name | Material | C | Mn | Si | Cr | S | P |

CMAX-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-3 | 65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

CMAX-4 | B2 | 0.70-0.85 | 0.70-0.80 | 0.17-0.37 | 0.2-0.7 | ≤0.03 | ≤0.03 |

CMAX-5 | 75SiMn | 0.70-0.90 | 0.70-1.20 | 0.4-0.8 | ≤0.25 | ≤0.03 | ≤0.03 |

CMAX-6 | Wear-resistant Alloy | 0.50-0.65 | 0.4-1.0 | 1.4-1.8 | 0.9-1.2 | ≤0.03 | ≤0.03 |

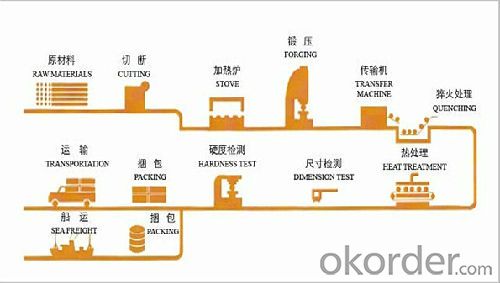

3. Production Process for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

3. Testing Methods for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

3. Packing Details for HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- Usually after rusting,Did you peel it?If it isNeed to do film processingIf notPlease look for the coating factoryBetter paint (such as epoxy ester, etc.)

- Q: Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good. At least spend money on research and development, then the quality should be all right.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

HRC60-HRC65 Forged Steel Grinding Ball with DIA0.75’’-DIA6’’ Used for Mine, Power Station, Chemical Industry, etc

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords