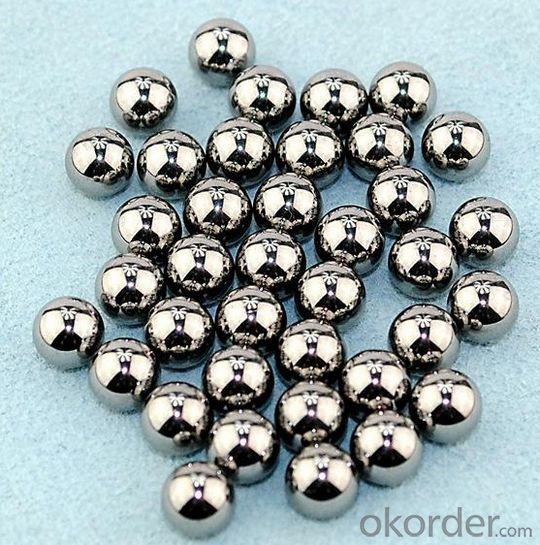

STAINLESS BALL WITH BEST QUALITY AND LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

G100 6mm SS304 stainless steel ball for bearings(SGS approved) )

304 Stainless Steel Balls

Applied Area304 stainless steel ball can be used in iatrical instrument, chemical industry, aviation. Plastic hardware: scent bottle, sprayer, valve, nail polish, switch, washing machine, fridge, air condition, medicinal materials, automotive fittings, bearing, nursing

bottle and so on.

Speciality representative of Austenitic stainless steel. it is nonmagnetic, but magnetic after rolling, and the magnetism can be taken out, HRC≤26.It has good antirust and anticorrosive capability.

316 Stainless Steel Balls

Applied Are316 stainless steel ball is used in many special industry as iatrical instrument, chemical industry, aviation, scent bottle, sprayer, valve, nail polish, mobile phone fittings.

Speciality Austenitic stainless steels, It is the best steel ball in the steel ball area,HRC≤26,its Capability is better than 304 stainless steel ball.

420 Stainless Steel Balls

Applied Area420 stainless steel ball is used in the industry of high precision and antirust: motorcycle fittings, chain wheel,

stainless steel bearings, plastic bearings, craftwork, valve, petroleum and so on.

Speciality It is also called stainless iron, it is magnetic and has good antirust capability. The HRC is 50-55

Product Name | stainless steel ball |

Service | Your inquiry will be replied within 12 hours. |

Brand | HT |

Material | AISI 304, AISI 316, AISI 316L, AISI 420, AISI440, AISI440C and etc. |

Size | 0.7mm-25.4mm |

Feature | High polished, high precision, easy storage. |

Antirust Way | Provide dry packaging & slushing oil packaging. |

Grade | G10-G1000 |

Hardness | HRC 58-62 (If you have special requirements, please tell us.) |

Sample | Free |

Stock | There are emergency stocks for regular sizes. |

Packing Method | Standard Seaworthy Export Packing or Customized Packing |

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- Our country or international, in all casting production in 60 ~ 70% by sand casting is produced, of which about 70% is used in the production of clay sand. The main reason is that the cost of sand casting is low compared with other casting method, simple production process and short production cycle. So as the car engine cylinder body the cylinder head, crankshaft castings are produced using clay wet sand molding process. When the wet type can not meet the requirement to consider the use of clay sand table dry sand, dry sand mold or other sand.

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- Casting parts do not need to provide drawings of casting blank, the casting factory according to your drawings in the required surface will be sufficient allowance, and the rest of the size according to the mechanical design manual and the casting manual can be found. The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- A: in the design of metal castings in a complex shape, if the production process is very difficult, should not affect the casting conditions, try to make the casting has simple shape, strong structure change, removed from metallic die for.

Send your message to us

STAINLESS BALL WITH BEST QUALITY AND LOWEST PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 40000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords