High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Process Line of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

RAW MATERIALS → CUTTING → STOVE → FORGING → TRANSFER MACHINE → QUENCHING → HEAT TREATMENT → DIMENSION TESE →PACKING →TRANSPORTATION OR SEA FREIGHT

Chemical Elements of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

C | Si | Mn | Cr | S | P |

0.50-0.65 | 0.15-0.37 | 0.6-1.2 | ≤0.25 | ≤0.04 | ≤0.04 |

0.7-0.9 | 0.45-0.75 | 0.7-1.25 | 0.11-0.4 | ≤0.04 | ≤0.04 |

Specification and Hardness of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

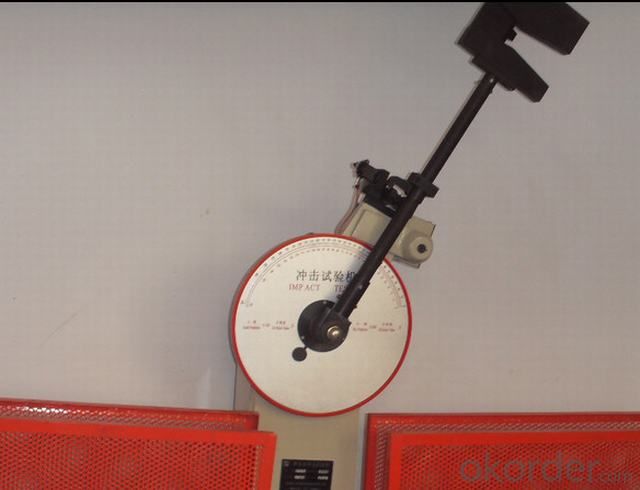

Nominal diameter (mm) | Diameteical tolerance (mm) | Weight of signal forging Ball in average (g) | Number of piece of one ton forging ball in average | Surface hardness (HRC) | Impact toughness (j/cm²)) |

φ20 φ25 φ30 φ40 φ50 | +2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1946 |

50-65 |

≥12 |

φ60 φ70 φ80 φ90 φ100 | +3 -2 | 888 1410 2104 2996 4110 | 1126 709 475 333 243 | ||

φ110 φ120 φ130 | +4 -2 | 5457 7102 9030 | 182 140 110 |

45-60 | |

φ140 φ150 | +4 -3 | 11278 13871 | 88 72 |

Application fields of High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

1).Metal mines 2).Cement plants 3).Power station 4).Chemical industry

5).Chemical engineering

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- Those should be head prints. If required, it would be better to throw with a single grinding head.

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: The casting sand is going on

- 2, causes(1) sand mold (core) strength is not high, when the box a little reason will fall off.(2) the strength of sand mould (core) is not high, it can not stand the erosion of molten steel.(3) box sand mould (core) crush.(4) high strength under high temperature, warpage, deformation and protuberance into the cast steel under the action of high temperature molten steel.(5) the floating sand in the air hole of the sand mold falls, especially when the floating sand falls in the casting, and the floating sand on the surface of the sand mold is easy to fall through the air vent.(6) when the box is closed, the surface of the mold cavity and the surface of the sand core are not cleaned, and the sand (core) surface has floating sand and so on.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: Heat treatment process and purpose of casting parts

- Natural aging (also known as Chang Hua): lost in the open, the sun and rain, can have experienced years of wind and frost.

- Q: Can the casting part be phosphating with the phosphating solution of the pickling board?

- Phosphating. But it's not necessary. Because casting parts have strong corrosion resistance.

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- There is YW1 best, if not using YG6X, YG8 is ok!The speed should not be high, the greater the diameter, the lower the speed! For example, a diameter of 100 mm, speed is not greater than 80 rpm, each point is good!The main tool is the front angle to be larger, more than 6 degrees, and the groove should be wider and larger to reduce the cutting resistance! When the rear angle is properly reduced and the strength is increased, it is recommended to take 3 degrees.The main components are: spindle box, exchange gear box, feed box, slide box, tool post, tail frame, light bar, lead screw, bed, foot and cooling device.Spindle box: also known as the headstock, it is the main task of the rotary motion of the main motor came through the transmission mechanism of a series of positive and negative spindle to be required two different steering speed, the spindle box gives impetus to the movement of the box. Medium spindle is the key part of lathe. The stability of the spindle on the bearing directly affects the quality of the workpiece. Once the rotation accuracy of the main shaft is reduced, the value of the machine tool will be lowered.

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

1. Manufacturer Overview

| Location | Jiangyin City, Jiangsu Province, China |

| Year Established | 2012 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South America; Oceania; Eastern Europe; Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 5 - 10 People |

| Language Spoken: | English; Chinese; Spanish; Portuguese; Russian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

High Hardness No Broken Forged Grinding Ball Made In China In Top Quality

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords