Forged Steel Grinding Ball Made in China with Top Quality and little Breakage Rate

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mechanical Properties of Forged Steel Grinding Ball Made in China with Top Quality and little Breakage Rate

Code | Nominal diameter | Impact test Ak,J | Falling ball impact fatigue life | HRC | |

Surface | Heart | ||||

HN-75MNCr | ≤90 | >12 | ≥10000 | ≥62 | ≥58 |

>90 | ≥58 | ≥55 | |||

HN-40MNCr | ≤90 | ≥12 | ≥10000 | ≥55 | ≥52 |

>90 | ≥52 | ≥50 | |||

HN-65MN | ≤90 | ≥12 | ≥10000 | ≥60 | ≥42 |

>90 | ≥58 | ≥40 | |||

Chemical Composition of Forged Steel Grinding Ball Made in China with Top Quality and little Breakage Rate

Model | C | Mn | Si | Cr | S | P | Mo | V | Ti |

HN-40MNCr | 0.40-0.50 | 0.7-1.2 | 0.17-0.37 | 0.9-1.1 | 0.03max | 0.03max | 0.02max | 0.02max | 0.02max |

HN-65MN | 0.62-0.70 | 0.9-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | 0.02max | 0.02max | 0.02max |

HN-75MNCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.4-0.9 | 0.03max | 0.03max | 0.02max | 0.02max | 0.02max |

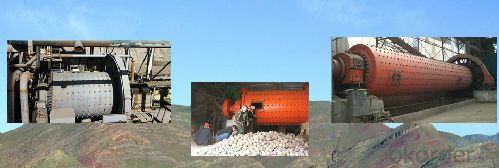

Product Description of Forged Steel Grinding Ball Made in China with Top Quality and little Breakage Rate

1)Size:from 20mm to 150mm(0.75''-6'')

2)Surface hardness to55-67HRC, volume hardness of 50-63HRC

3)Endurance test times>10000

4)Impact test>12AK.J/CM2

5)Material: HN-65MN,HN-75MNCr,HN-40MNCr meet client's special needs.

6)Chromium percentage: from 0.25 to 1.1%.

7)Heat treatment: cycles.

8)Production Technical: traditional hammer forging; Upsetting forged; Rolling forged

9)Application :Mining ,Cement plant, ,Power station,and other grinding industries

10)Certification:SGS/TUV/BV/COTECNA/ISO9001:2008

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.

- Q: What is the difference between casting and stamping parts?

- Cold stamping is generally no longer done by cutting, or only a small amount of cutting is required. The precision and surface state of hot stamping parts are lower than those of cold stamping parts, but they are better than those of castings and forgings, and the amount of cutting is less.Stamping is mainly based on process classification, can be divided into separation process and forming process two major categories.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 2, heat aging (artificial aging), also known as stress annealing, is to heat the casting to 550-650 degrees, insulation 2 - 4h, with the furnace cooling to 150 - 200T, and then baked.

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa; Mid East;South Asia;Southeast Asia;Eastern Asia;Southern Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

Forged Steel Grinding Ball Made in China with Top Quality and little Breakage Rate

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords