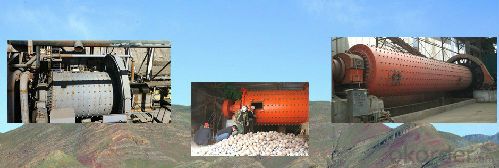

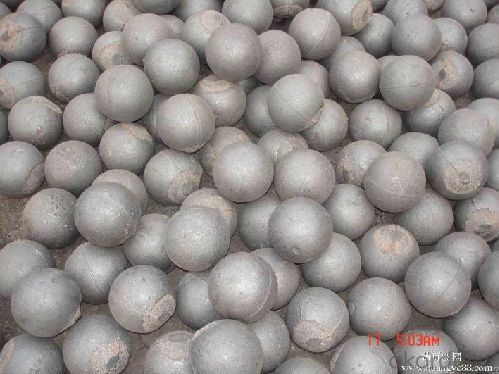

Forged Steel Grinding Ball with no Breakage in Top Quality and Top Hardness

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Forged Steel Grinding Ball with no Breakage in Top Quality and Top Hardness

1)Size:from 20mm to 150mm(0.75''-6'')

2)Surface hardness to55-67HRC, volume hardness of 50-63HRC

3)Endurance test times>10000

4)Impact test>12AK.J/CM2

5)Material: HN-65MN,HN-75MNCr,HN-40MNCr meet client's special needs.

6)Chromium percentage: from 0.25 to 1.1%.

7)Heat treatment: cycles.

8)Production Technical: traditional hammer forging; Upsetting forged; Rolling forged

Type and Chemical Composition of Forged Steel Grinding Ball with no Breakage in Top Quality and Top Hardness

Brand | Grade | C | Mn | Si | Cr | S | P |

Hardness-1 | 50Mn | 0.48-0.56 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

Hardness-2 | 60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

Hardness-3 | 65Mn | 0.6-0.7 | 0.9-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max |

Hardness-4 | 75MnCr | 0.70-0.85 | 0.7-0.8 | 0.17-0.37 | 0.2-0.7 | 0.03max | 0.03max |

Hardness-5 | Rail IronⅠ | 0.5-0.65 | 0.60-1.0 | 0.15-0.37 | 0.25max | 0.04max | 0.04max |

Hardness-6 | Rail IronⅡ | 0.60-0.8 | 0.90-1.2 | 0.20-0.40 | 0.20-0.8 | 0.07max | 0.03max |

Package of Forged Steel Grinding Ball with no Breakage in Top Quality and Top Hardness

iron drum(850-920kg per drum)

bag package(1000kg per bag)

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: How much is the amount of electrophoretic paint per square meter used in the casting?

- It was a very simple question, and it was complicated by what you said.In general, when the final thickness of 15-20 microns, cathode electrophoresis paint can be coated per kilogram of 6-8 square meters, the current general cathode electrophoresis paint for the price of 22 yuan / kg, so the cathodic electrophoresis electrophoresis paint cost at 4 yuan / square meters.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- 3, the resonance method is cast on its resonant frequency vibration 1060ndn, to eliminate the residual stress in casting.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: What foundry factories are used in the casting parts of China's major automobile manufacturers?

- This is too muchYou do not have a specific list of statistics, but there are many foundries in china!Moreover, car prices are unlikely to be ordered in the local factories!

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing refers to making the first sample to confirm to the customer

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- There is YW1 best, if not using YG6X, YG8 is ok!The speed should not be high, the greater the diameter, the lower the speed! For example, a diameter of 100 mm, speed is not greater than 80 rpm, each point is good!The main tool is the front angle to be larger, more than 6 degrees, and the groove should be wider and larger to reduce the cutting resistance! When the rear angle is properly reduced and the strength is increased, it is recommended to take 3 degrees.The main components are: spindle box, exchange gear box, feed box, slide box, tool post, tail frame, light bar, lead screw, bed, foot and cooling device.Spindle box: also known as the headstock, it is the main task of the rotary motion of the main motor came through the transmission mechanism of a series of positive and negative spindle to be required two different steering speed, the spindle box gives impetus to the movement of the box. Medium spindle is the key part of lathe. The stability of the spindle on the bearing directly affects the quality of the workpiece. Once the rotation accuracy of the main shaft is reduced, the value of the machine tool will be lowered.

- Q: The difference between sheet metal and casting parts

- Commonly used in machine tools casting material is gray cast iron, casting bearing alloys can also be.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa; Mid East;South Asia;Southeast Asia;Eastern Asia;Southern Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port; Tianjin Port; Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Ball; Grinding Rod; Cylpeb; Grinding Media; Ball Mill Ball |

| Product Price Range | Average |

Send your message to us

Forged Steel Grinding Ball with no Breakage in Top Quality and Top Hardness

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords