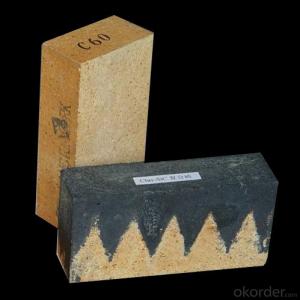

High Alumina Brick Silicon Nitride Bonded Silicon Carbide Products - Aluminum Electrolysis Slot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application: aluminum electrolysis bath side wall, the chemical industry reaction tank, a variety of high temperature abrasion resistant lining board, outlet bricks, furnace heating furnace and the aluminum liquid conveying pipe.

Features: has the advantages of long service life, high hardness, high temperature strength, liquid aluminum erosion and thermal erosion abrasion resistance, anti acid and alkali, corrosion resistance, low linear expansion rate higher characteristic, thermal conductivity.

Product name

Silicon nitride bonded

silicon carbide products

Chemical composition (%)

SiC ≥ 72.0

Si3N4 ≥ 21.0

Fe2O3 ≤ 0.3

Si ≤ 0.3

Display the porosity (%)

≤ 16.0

The volume density(g/cm3)

≥ 2.68

Compressive strength at room temperature (Mpa)

≥ 180.0

Flexural strength

(Mpa)

Normalatmospheric temperature

≥ 45.0

1400℃ ≥ 55.0

Thermal conductivityλ(W/m·K)

The experimental temperature

650℃

19.5

The experimental temperature

1000℃

17.2

Coefficient of temperature conductivity

α(cm2/s)

The experimental temperature

650℃

0.064

The experimental temperature

1000℃

0.053

Linear expansion rate

α30—1000

4.02×10-6(k-1)

α30—1100

4.06×10-6(k-1)

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- In the course of the production of lime kiln, the local block of refractory brick is a very dangerous signal. It is suggested that you stop the kiln to prevent the collapse of a large area. Lime kiln is the main equipment for the production of limestone kiln and rotary kiln is two, with the growth of calcium carbide lime kiln industry, iron and steel industry, the construction industry to the amount of limestone has become the main production equipment, and refractory bricks became the heart of lime kiln.

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: Are there any differences between insulating bricks and refractory bricks?

- The refractoriness of insulating bricks is generally below 1400 tons, while the refractoriness of refractory bricks is above 1400 degrees. 3. density insulation bricks are generally lightweight insulation materials, the density is generally in 0.8-1.0g/cm3, and the density of refractory bricks are basically above 2.0g/cm3.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Before making bricks, the raw materials are usually tested and tested to see if the aluminum content is up to standard

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- When an object is heated, the particle moves faster and thus occupies additional space. This phenomenon is called dilation.

- Q: What causes breakage of refractory bricks?

- Refractory brick is a non metal mineral products can be used in the high temperature of 1550 DEG C under belongs to a class of inorganic, used in high-temperature furnace lining materials as protection kiln, which causes damage, usually have these points.Furnace temperature is not clear, there is no corresponding choice of refractory bricks.Physical impact, abrasion and erosion cause damageChemical factors, especially chemical industry, should be made of refractory bricks, which should be resistant to penetration and erosionIV: products from the factory when the factory did not pass the quality inspection standards

- Q: What is the difference between metal compounds and metal solid solutions?

- Sigma phase belongs to Affirmative system, there are 30 atoms in the unit cell, two element alloy, sigma phase formation is related with the following conditions: (1) the atomic size difference, phase difference between the maximum sigma atomic radius of a tungsten cobalt, the atomic radius difference is 12%. (2) there is a set of cubic lattice elements (coordination number 8), and another component is face centered cubic or dense six square lattice (coordination number is 12). (3) appear in "average number of races" (s+d layer electron number) in the range of 5.7 ~ 7.5. The region of the presence of sigma in the two - element alloy is shown in table 3. In the three element system, the concentration and temperature range of the formation of the sigma phase are affected by the addition of third components. Usually in chromium stainless steel in Fe Cr phase, in Fe - Cr - Mn three yuan, sigma phase iron chromium and chromium can form Mn two element, when the addition of manganese in stainless steel, will promote the formation of sigma phase, and stabilizes the wide temperature range. Many of the Fe Cr alloy elements. The phase temperature range increases. In less than 820C stable Fe Cr phase, silicon promotes the formation of D phase and the stable temperature increased to 900 to 960 DEG C, manganese and molybdenum can improve the temperature stability of sigma phase to 1000 DEG C.

Send your message to us

High Alumina Brick Silicon Nitride Bonded Silicon Carbide Products - Aluminum Electrolysis Slot

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords