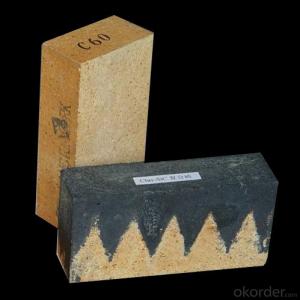

High Alumina Brick - High Strength Refractory Bricks Approved GB/T10699-1998

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Refractory Brick approved GB/T10699-1998

Thermal Conductivity:<0.35w/m.k

Density:500-700kg/m3

Temperature:1580C-1700C

Company Introduction:

Surya Thermal Insulation Material Co.,Ltd major exports all kinds of insulation material:calcium silicate board,ceramic fiber blanket,insulation bricks and other insulation material.We can supply calcium silicate block insulation ,pipe insulation,curved sheet and paste with kinds of denaity and sizes.Our products can be widely used in industries of metallurgy,building material,petrochemistry,nonferrous metal,machinery,electric power,light-industry and so on.Annual output is 60,000 cubic meters.The products have been exported to more than fifty countries and areas in the world,such as Asia,Europe,America,Africa etc,and also get high reputation from our customers.

Refractory bricks:---Description:

Heat insulation refractory bricks is my company the American advanced standard reference to the development and production of a kind of high efficient, energy saving, high grade product. The products have been widely used in metallurgical hot dip galvanized furnace, silicon steel processing furnace, blast furnace stove; The petrochemical industry ethylene cracking furnace, hydrogen furnace, a transformation furnace, sulfur recovery units; And other such as roller kiln, spindle type kiln, prevent (fight) carburizing (n) the stove and so on thermal device, and satisfactory results.

Refractory bricks ---Product features :

1. High temperature resistant,

2. Performance is good,

3. High strength,

4. Show low porosity,

5. An acid, alkali resistant, aggressive good, etc.

Refractory bricks---Technical parameters:

Al2O3%>45SiO2%40Fe2O3% <1.0 Cao%1.7Normal temperature the flexural strength MPa1.0-1.3Volume density %0.52-1.25Normal temperature compression strength MPa1.2-3.4Softening temperature °C1250Thermal shock stability (water) times / 1000 degrees air cold>15Coefficient of thermal conductivity W / (m.k) 350 degrees +-10 degrees-1Heavy burn line change %-1 1300*12hThe highest use ° C temperature1230-1760 |

Refractory bricks---Application:

Mainly used for thermal boilers, cement kiln, glass furnace, gas furnace, fertilizer, blast furnace hot-blast stove, coking furnace, electric furnace, casting and casting steel brick.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- In the course of the production of lime kiln, the local block of refractory brick is a very dangerous signal. It is suggested that you stop the kiln to prevent the collapse of a large area. Lime kiln is the main equipment for the production of limestone kiln and rotary kiln is two, with the growth of calcium carbide lime kiln industry, iron and steel industry, the construction industry to the amount of limestone has become the main production equipment, and refractory bricks became the heart of lime kiln.

- Q: What are the common thermal insulation materials for thermal conductivity?

- The single organic insulation material should be the best polyurethane in the field. In accordance with the production process can be divided into on-site foam polyurethane and factory prefabricated rigid foam polyurethane board. The scene is polyurethane foam isocyanate and polyol to cool (polyether or polyester) two components as the main raw materials with additives, the on-site spraying construction with thermal insulation and waterproof function of the rigid foam material.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- The T3 in T3 refractory bricks refers to the model indicating that the refractory brick model is T-3, and that the corresponding T-3 model is 230*114*65 (mm)

- Q: What is the density of a super high alumina brick and what is the price?

- Super high alumina brick, alumina content of 80% bricks, bulk density of 2.7g/cm3 or more, the factory price of about 1900 yuan

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: Which is better, the soft core or the hard core?

- When the current through the wire, it will produce a magnetic field in the vertical plane space of the wire, if there is a current two wire close by in the same direction, because they produce a magnetic field in the direction is opposite, it will produce a repulsive force is due to the magnetic field force. They will mutually inhibit current intensity of the other party, caused by the reduction of current in the wire, this inhibition of each current intensity, we called wire inductance. When the AC current line frequency is high, the inductance is stronger.

- Q: How to distinguish the good or bad of the high aluminum brick?

- Weigh the weight of the next block. According to the weight standard, a high alumina brick is 3.9 kg in weight, two in high alumina brick, three in high aluminium brick and 4.5 kg in 4.2. The same grade, the same type of high alumina brick, if the weight of a single brick to this standard, but for high quality high alumina brick, otherwise, can not reach such a weight, it shows good quality. If there is a crack, a large piece of broken angle, four sides of inequality, it is for substandard products.

- Q: What is the difference between high alumina brick and clay brick?

- Light clay brick, refractory material is a kind of high porosity, low density, low thermal conductivity of refractory material, refractory materials called lightweight refractories, it includes insulating refractory products, refractory fiber and refractory fiber products. Heat insulation refractory material is characterized by high porosity, general 40%-85%, low volume density, lower than 1.5g/cm3, low thermal conductivity, generally lower than 1.0W (m.K). The utility model has the function of heat insulation of an industrial furnace, and can reduce the heat dissipation loss of the kiln, save energy, and can reduce the quality of the thermal engineering equipment. The mechanical strength, wear resistance and slag resistance of insulating refractory material are poor, and it is not suitable for the load-bearing structure of kiln and direct contact with slag, burden, molten metal and other parts.

- Q: What is the difference between metal compounds and metal solid solutions?

- A series of intermetallic compounds occurring between transition metals in intermetallic compounds. The most important are L sigma sigma phase and ves phase, they are topologically close packed (TcP) phase, they consist of a small atomic radius of a dense layer, which is inlaid with a large atomic radius of atomic structure, this is a highly dense pile. In addition to atomic size factors, their formation is also influenced by the concentration of electrons.

Send your message to us

High Alumina Brick - High Strength Refractory Bricks Approved GB/T10699-1998

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords