High Alumina Brick for Glass Kiln Thermal Insulating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alumina High Strength for Glass Kiln Thermal Insulating Brick

Product Description

The phosphate bonded high aluminum bricks are with high strength, low bulk density, low thermal, conductivity, high thermal shock resistance and the anti-spalling is good. Widely used in cement kiln,hot blast stove/furnace,EAF(electric arc furnace),coke oven door...

Structure& Advantage

for Our High Aluminum/Alumina Refractory Brick, Fireclay Bricks

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

4) The using temperature is 1600 c

5) Phosphate high alumina bricks,iso

6) High strength

7) Low thermal conductivity

8) Widely used in cement kiln.

9) Low creeping rate

10) High pressure

11) Excellent thermal shock resistance

12) High quality fireclay clinker

We Are Suppiler for

Below are some of our customers

Allied Mineral Products,inc

Refractories Incorporated

Srs Sorg Refractory Systems GmbH,

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

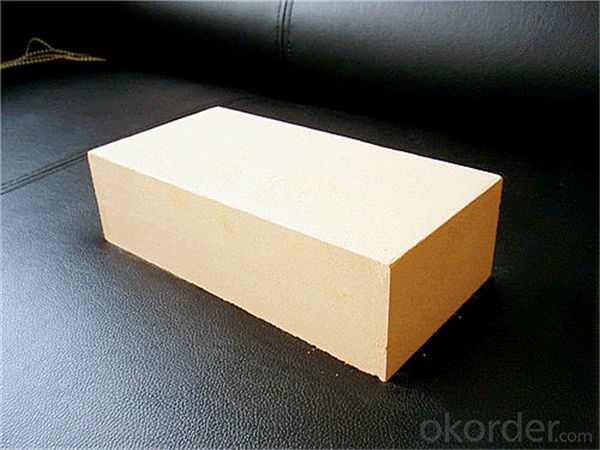

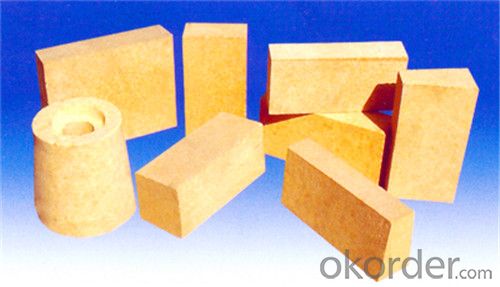

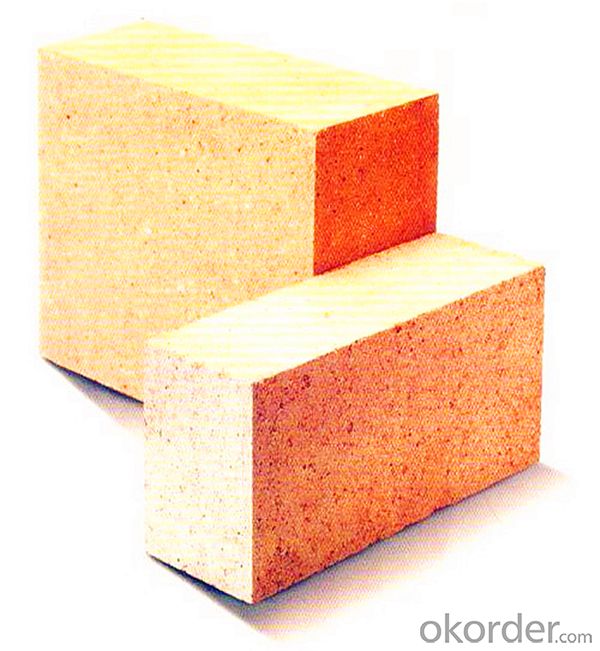

Major Images

Refractory High Alumium and Fireclay Brick

Specification for High Aluminum Refractory Brick

ITEM | UAL48 | UAL55 | UAL65 | UAL75 | UAL80 | UAL85 | ALP80 |

Refractoriness, ℃ | 1750 | 1770 | 1790 | 1790 | 1810 | 1810 | 1810 |

Apparent Porosity,% | 22 | 22 | 23 | 23 | 20 | 20 | 18 |

C.C.S, Mpa | 39 | 44 | 49 | 53 | 55 | 60 | 100 |

Refractories Under Load (0.2Mpa),℃ | 1420 | 1470 | 1500 | 1520 | 1500 | 1520 | 1550 |

Reheating Linear Change,% | 1450x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500x2h 0.1~-0.4 | 1500℃x2h 0.1~-0.4 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 | 1550x2h -0.5~+0.5 |

Al2O3 Content , % | 48 | 55 | 65 | 75 | 80 | 85 | 82 |

FAQ

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: What is the difference between corundum and high alumina??

- The main component of high purity 99 corundum brick is corundum sand,90 corundum brick is mainly composed of corundum sand and a small amount of Suzhou soil, mullite.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- People with the shaft kiln cement clinker kiln, because of small size, low calcination temperature, using only Al2O3 containing a single clay brick is 30 ~ 40%, the rotary kiln was improved in the early Yuan faith this experience, use of high alumina brick and clay brick, from 60s onwards, due to large scale kiln and to strengthen the operation of the high temperature parts of kiln lining, alkaline brick masonry is widely used, the main varieties are: magnesia chrome brick, magnesia spinel brick and dolomite brick.

- Q: What are the high temperature refractory mortars made of?

- Products used in metallurgy, building materials, machinery, chemical, power industry, industrial thermal furnace, for masonryBuilding clay brick, high alumina brick and corundum brick have the characteristics of full grey seam, good airtightness, high bonding strength, high temperature performance and suitable construction time

- Q: What is spalling resistant high alumina brick?

- Spalling resistant high alumina brick is a kind of high alumina brick. Antistripping high alumina brick with high grade bauxite and containing Zr02 synthesis as raw material, according to a certain proportion by high pressure molding system in sintering products, products with anti stripping ability, and have the anti erosion potassium, sodium, sulfur, chlorine and alkali salt, low thermal conductivity and other properties that is the transition zone of cement kiln and decomposition of ideal material with remarkable characteristics, the product is good thermal shock resistance, strong ability to adapt to the environment. It is used in the preheating or decomposing furnace, grate cooler and so on.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: What's the weight of the refractory bricks?

- According to shape and size can be divided into standard brick, ordinary brick, special brick, etc.. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- Refractory bricks are stone powder and clay paste. They are fired in a kiln of 1300 degrees. The upper limit is 1500 degrees above normal pressureRefractory bricks - refractory materials of a specified shape and size.

Send your message to us

High Alumina Brick for Glass Kiln Thermal Insulating

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1044 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords