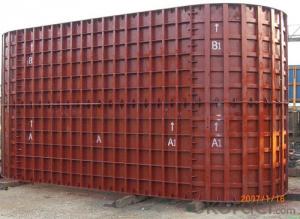

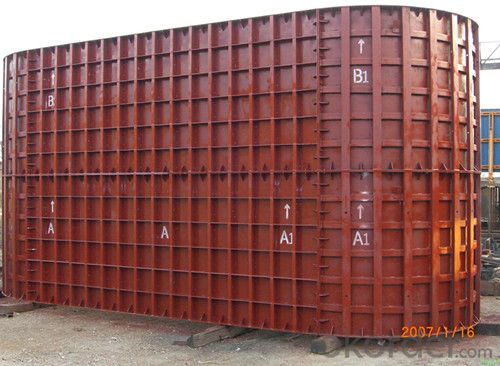

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: How does steel formwork prevent concrete shrinkage and cracking?

- The use of steel formwork is essential in preventing concrete shrinkage and cracking. By offering robust and rigid support during the curing process, it ensures that the concrete retains its shape and hardens properly. Acting as a mold, the steel formwork securely holds the concrete in place, preventing any shrinkage or cracking as it dries. Concrete shrinkage and cracking are primarily caused by the loss of moisture during curing. As the water evaporates from the concrete, it causes the material to shrink, potentially leading to cracks if not adequately supported. To prevent this shrinkage, steel formwork provides a tight enclosure for the concrete, ensuring that it retains its moisture and doesn't dry out too quickly. This controlled drying process allows for even curing, minimizing the risk of shrinkage and cracking. Moreover, steel formwork provides stability and support to the concrete, preventing any movement or shifting as it hardens. This stability helps distribute forces and stresses evenly, reducing the likelihood of cracking or structural failure. Furthermore, the smooth and rigid surface of steel formwork contributes to achieving a high-quality finish on the concrete. This eliminates any irregularities or imperfections that may weaken the structure or make it more susceptible to cracking. In conclusion, steel formwork is vital in preventing concrete shrinkage and cracking by offering support, stability, and moisture retention during the curing process. Its strong and rigid structure ensures the integrity of the concrete and enhances its durability, reducing the risk of structural issues.

- Q: What are the different surface treatments available for steel formwork panels?

- Some of the different surface treatments available for steel formwork panels include galvanizing, powder coating, and epoxy coating. These treatments help to protect the panels from corrosion, enhance their durability, and improve their overall appearance.

- Q: Can steel formwork be used for bridge construction?

- Bridge construction can indeed utilize steel formwork. This adaptable and robust material provides the necessary strength and stability throughout the construction process. It is suitable for various types of bridges, including beam bridges, arch bridges, and cable-stayed bridges. Steel formwork brings numerous advantages to bridge construction, such as easy assembly and disassembly, a high capacity for bearing loads, resistance to different weather conditions, and the ability to be reused multiple times. Moreover, steel formwork enables precise shaping and finishing of bridge components, ensuring a final structure of exceptional quality and aesthetic appeal. In summary, steel formwork proves to be a dependable and efficient choice for bridge construction projects.

- Q: How does steel formwork contribute to improved construction efficiency?

- Steel formwork contributes to improved construction efficiency in several ways. Firstly, steel formwork is durable and long-lasting, allowing it to be reused multiple times. This reduces the need for frequent replacement and lowers overall construction costs. Secondly, steel formwork is lightweight and easy to assemble, making it quick to install and dismantle. This saves time and labor during the construction process. Additionally, steel formwork provides a smooth and even surface finish, resulting in high-quality concrete structures. This eliminates the need for extensive polishing or plastering work, further enhancing construction efficiency. Overall, steel formwork improves construction efficiency by reducing costs, saving time, and ensuring superior concrete finishes.

- Q: How does steel formwork affect the construction timeline?

- Steel formwork can significantly impact the construction timeline in a positive way. Due to its durability and strength, steel formwork offers faster installation and removal compared to traditional timber formwork. This expedites the construction process, allowing for quicker concrete pouring and curing times. Additionally, steel formwork provides better dimensional accuracy and reusability, reducing the time required for adjustments and replacements. Overall, the use of steel formwork can help streamline construction activities, leading to shorter project durations and improved efficiency.

- Q: Can steel formwork be used for underground culverts?

- Yes, steel formwork can be used for underground culverts. Steel formwork is known for its durability, strength, and ability to withstand heavy loads and pressure. This makes it suitable for constructing underground culverts, which are designed to carry water, sewage, or other fluids below the ground surface. Steel formwork provides a rigid structure that can withstand the weight of the soil and any traffic loads above it, ensuring the stability and longevity of the culvert. Additionally, steel formwork is versatile and can be easily customized to accommodate different sizes and shapes of culverts. Overall, steel formwork is a reliable and efficient choice for constructing underground culverts.

- Q: Can steel formwork be used for underground structures?

- Indeed, steel formwork can be utilized for underground structures. An adaptable and long-lasting choice, steel formwork proves ideal for the creation of underground structures, including basements, tunnels, and underground storage facilities. Its exceptional strength and stability enable it to withstand the pressure and burdens related to underground construction. Steel formwork establishes a firm framework for pouring concrete, guaranteeing proper shaping and alignment of the structure. Its capacity to endure high pressures and forces permits the construction of robust and enduring underground structures, capable of withstanding the surrounding soil and water pressure. Moreover, steel formwork is reusable, rendering it an economically advantageous option for underground construction projects. Effortless dismantling, cleaning, and future utilization contribute to reduced costs and environmental impact. Furthermore, steel formwork facilitates efficient construction processes and expedites completion times. Its modular nature allows for swift assembly and disassembly, saving time and labor compared to traditional formwork methods. Nevertheless, prior to employing steel formwork, it is crucial to consider the specific requirements and conditions of the underground structure. Factors such as soil conditions, water table levels, and the intended use of the structure should undergo evaluation to ensure that steel formwork is the most appropriate choice. Professional engineering expertise and comprehensive planning are essential for the successful implementation of steel formwork in underground construction projects.

- Q: How does steel formwork contribute to better site organization?

- Steel formwork contributes to better site organization in several ways. Firstly, steel formwork is highly durable and reusable, which means it can be used multiple times on different construction projects. This eliminates the need for frequent replacement and reduces waste on site. The ability to reuse steel formwork also reduces storage space requirements, as it can be easily stacked and stored when not in use. Secondly, steel formwork is adjustable and customizable, allowing it to be easily modified to fit different shapes and sizes of concrete structures. This flexibility enables efficient use of space on site, as the formwork can be tailored to the specific requirements of each project. This ensures that the construction process is organized and streamlined, minimizing the need for additional materials or adjustments. Furthermore, steel formwork is known for its high strength and stability, which enhances site safety. Its robust structure provides a secure platform for workers to carry out their tasks, reducing the risk of accidents or injuries. This promotes a safer working environment and improves overall site organization. Steel formwork also contributes to better site organization by facilitating faster construction cycles. Its quick assembly and disassembly process allows for efficient and smooth workflow, enabling construction projects to be completed in a timely manner. This helps to minimize delays and ensures that the site is well-organized and productive. Lastly, steel formwork can be easily integrated with other construction systems and technologies. This compatibility allows for seamless coordination between different components of the project, promoting better site organization. Whether it is integrating with scaffolding systems or connecting to other structural elements, steel formwork ensures a cohesive and well-organized construction site. In conclusion, steel formwork contributes to better site organization through its durability, adjustability, strength, and compatibility with other construction systems. Its ability to be reused, customized, and integrated with other components enhances efficiency, safety, and productivity on construction sites.

- Q: Is steel formwork suitable for projects with high concrete strength requirements?

- Indeed, steel formwork proves to be a fitting choice for endeavors demanding robust concrete potency. Renowned for its exceptional fortitude and endurance, steel formwork emerges as an ideal candidate for projects necessitating elevated concrete strength. It deftly endures the concrete's pressure and weight, assuring steadfastness and structural integrity throughout the pouring and curing phases. Furthermore, steel formwork grants the concrete a seamless and uniform surface, crucial in attaining superior strength and excellence in the ultimate outcome. Moreover, the reusability of steel formwork renders it a cost-efficient alternative for ventures requiring substantial concrete strength.

- Q: Can steel formwork be used for both horizontal and vertical concrete elements?

- Yes, steel formwork can be used for both horizontal and vertical concrete elements. Steel formwork provides strength, stability, and durability, making it suitable for a wide range of construction projects. Its versatility allows for the creation of various shapes and sizes, making it a preferred choice for both horizontal slabs and vertical walls.

Send your message to us

Heavy Steel Formwork for Dam Construction with Anti-Corrosion Paint

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords