Heat Resistant Best selling heat resistant glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

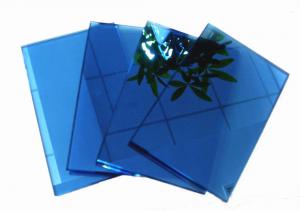

Heat Resistant Best selling heat resistant glass

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

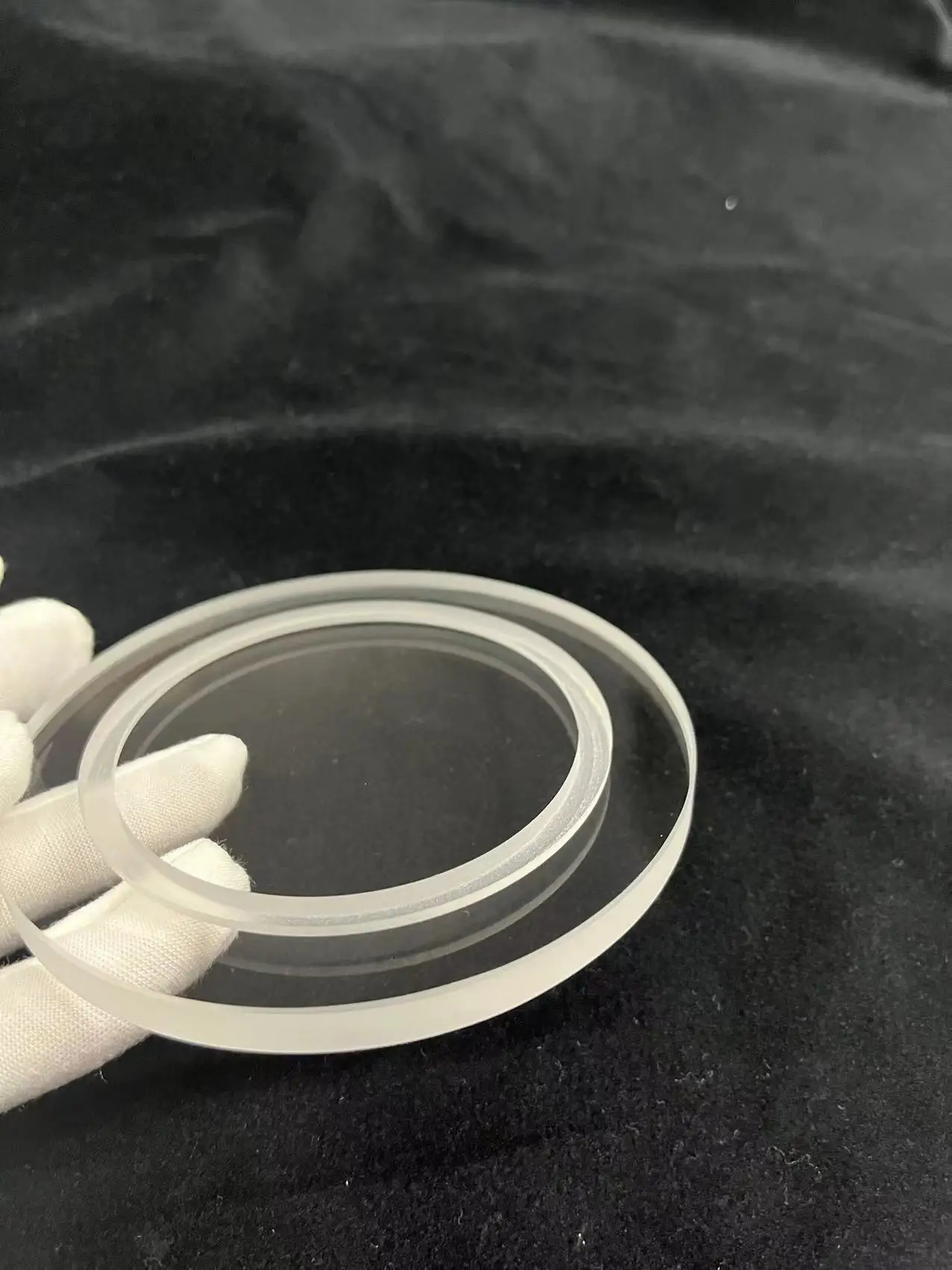

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

Packing & Delivery

* For small quantities, you can choose DHL or FedEx. It is safe and fast. We have a good rate withthem. Please contact us for

rates.

* Ocean Shipment is economical for big quantity.

* We can also help Custom clearance at destination port and deliver goods to your warehouse or office. And the cost is extra.

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Brother and sister! I would like to get a fire on the material of the network in the demise of the silence, but do not know where to do online, in addition to Google and Alibaba, do fire products more obvious website, products are; fire bags, fire Blocking materials and other products. Thank you so! I have a little points please Thank you so! More

- On the third floor which buddy problems ah people say not in the Google and Ah Baba to get you also called people here to do the above Hai Hai demise hit the silence of the turtle burst stroke I think this buddy is to get the personal bar dry this line did not Hard relationship is not ok, how bad is it?

- Q: Decoration materials fire rating

- Class A: incombustible Building materials: almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable Building materials: no any flame retardant effect, easy to burn, fire risk is great.

- Q: What are the fireproof materials?

- Water and wet cotton quilts...

- Q: Fire doors with fire insulation materials which?

- Fire doors with fire insulation materials fire doors made of steel materials, door frames, door frames and door panels, doors if filled material, then fill the human body non-toxic harmless fire insulation materials, and with fire hardware accessories With a certain fire resistance of the door. Fire doors general technical conditions of the standard This standard specifies the wood fire door product classification, size specifications, technical requirements, test methods, inspection rules, logo packaging, transportation and storage. This standard applies to the use of wood or wood products for the door frame, door frame, door panel fire door. Emergency and statistical functions, the system can automatically display on the computer specified cardholder's physical location, easy to contact in time. Fire and other emergencies, the electronic fire door will automatically open, easy to escape, the entrance can also be automatically opened; when the illegal out of time, will automatically alarm.

- Q: If you really have this kind of material, please tell me, if you can tell where you can find it really is so much more thanks

- Urea formaldehyde. It is a thermosetting plastic that probably meets your requirements. General hardware shop also have to sell it!

- Q: What is the meaning of the plastic raw material fire rating HB?

- HB is the lowest level of fire rating, it can be said is not fire.

- Q: Fire-resistant coatings are generally water-based or oily

- Common fire-resistant coatings on the market are also water-soluble (oily). Fire retardant coating from the dispersion medium can be divided into: water and solvent-based two. Water-based fire retardant coating: water as a dispersion medium, the emulsion for the film-forming material, in a variety of flame retardants, filler composition of water-based fire retardant coating. Solvent (oil) fire retardant coating: organic solvent for the thinner, resin for the film-forming material, in a variety of flame retardants, fill the composition of solvent-based fire retardant coating. The difference between the two: water-based fire retardant paint green, environmentally friendly fire-resistant coating, is the national and industry recommended species. Solvent-based fire retardant coating because of the organic film in the process of drying, benzene, xylene and other needs to be volatile, so people and the environment have a certain impact, but in a certain environment, solvent-based fire retardant coating fire resistance, water resistance Chemical resistance is water-based fire retardant coating can not reach. With the continuous progress of technology, the future may be completely eliminated solvent-based fire retardant coating.

- Q: What is a level of fire. Secondary fire, three fire (steel)

- Is to see you fire for hours. General secondary fire is 1.5 hours it

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability UL94 grade is the most widely used standard for combustible properties of plastic materials. It is used to evaluate the ability of the material to be extinguished after being ignited. According to the burning speed gallbladder Ding book scratching calcium difference water to promote the alarm, burning time, anti-drop ability and drop beads can burn a variety of judging methods. Each test material can be a lot of values ??depending on color or thickness. When a material of a product is selected, its UL grade shall meet the thickness requirements of the wall part of the plastic part. UL grade should be reported along with the thickness value. It is not enough to report only UL grade without thickness. Plastic flame retardant grade by HB, V-2, V-1, to V-0 step by step increase. 1.HB: UL94 standard in the bottom of the flame retardant grade. Requires a sample with a burning rate of less than 40 mm per minute for samples of 3 to 13 mm; a sample less than 3 mm thick, a burning rate of less than 70 mm per minute; or extinguished at 100 mm mark. 2. V-2: After two 10 seconds of burning test, the flame was extinguished in 60 seconds and no burner could fall. 3.V-1: After two 10-second burn tests on the sample, the flame was extinguished in 60 seconds and no combustibles could fall. 4.V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds and no combustibles can fall.

- Q: Must be fireproof material!

- Can not. Polystyrene is flame retardant and non-flame retardant of the points, the flame is generally self-extinguishing. Polystyrene refers to the polymer from the styrene monomer by free radical polymerization synthesis of the polymer, the English name for the Polystyrene, Japanese name for the Poly ス チ ロ ー ル, referred to as PS. It is a colorless and transparent thermoplastic, with a glass transition temperature higher than 100 degrees Celsius, and is often used to make disposable containers that require temperatures that require boiling water, as well as disposable foam boxes.

Send your message to us

Heat Resistant Best selling heat resistant glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords