China hot selling glass high heat resistant ceramic glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

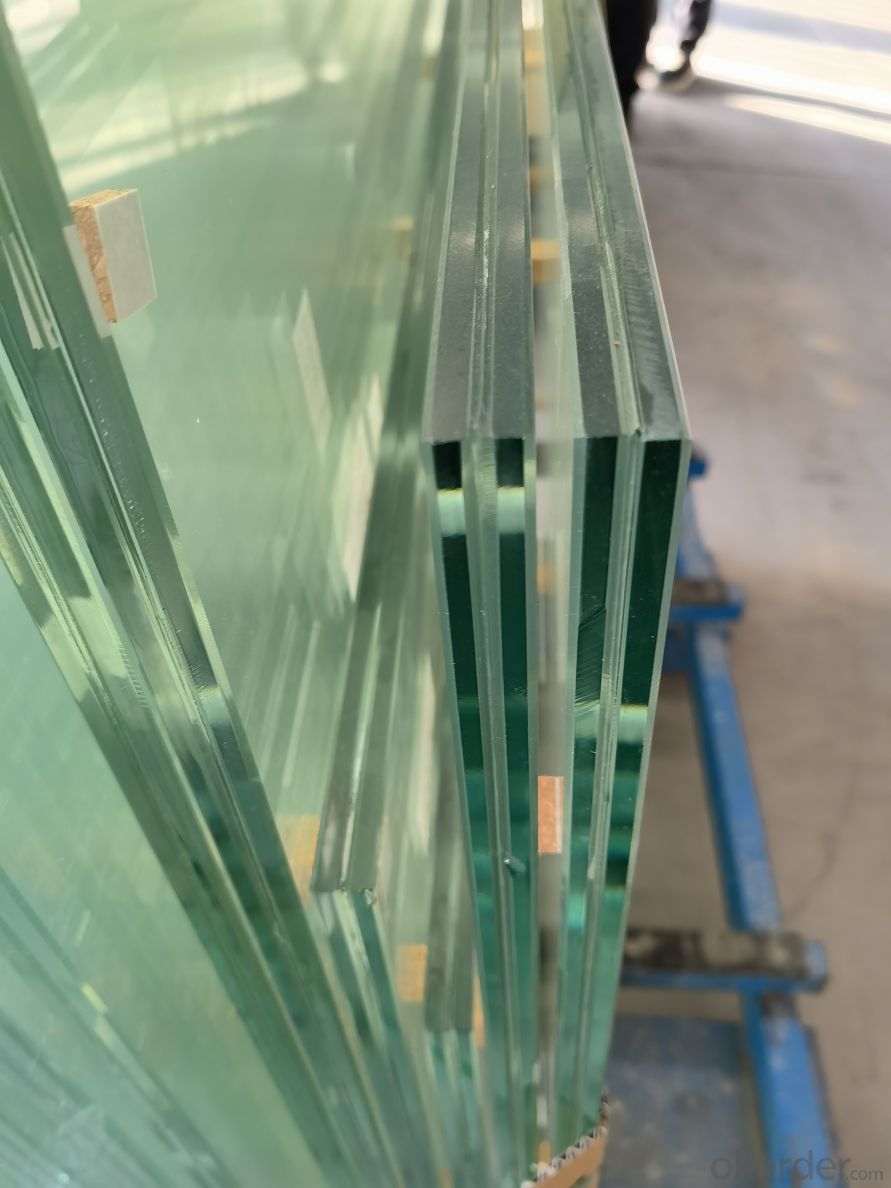

China hot selling glass high heat resistant ceramic glass

Advantages of Heat Resistant Glass

The main advantage of Heat Resistant glass is that it helps in insulation by reducing the heat gain and heat loss. Adding multiple layers of glass with gas infill further protects the windows and building from heat loss.

Another advantage of Heat Resistant glass is that it increases the energy efficiency in buildings. The reduced heat transfer lowers the electrical power consumption required for heating or cooling of the space. This drastically cuts down the electrical bills especially in areas subjected to extreme heat or cold. The use of low-e glass and reflective coatings can further improve the efficiency of the windows by further limiting the heat transfer.

Heat Resistant glass also helps in sound insulation and improves the acoustics of the place. The inert gas present in between the two panes of glass does not allow noise to pass through and acts as a barrier between the interiors of the building and the noise that is present outside the building .

The factory mainly produces

Borosilicate 3.3 heat-resistant glass is widely used in household appliances, electronics, instrumentation, optics, aerospace and other fields.

Borosilicate 3.3 heat-resistant glass has good thermal properties, mechanical properties, optical properties and ultra-high chemical stability. The visible light transmittance is 92%, and the high light transmittance in the near-infrared and ultraviolet bands exceeds 90%. The sign of fluorescence is far lower than that of soda lime glass.

1)Water resistance (International Organization for Standardization 719): Grade A

2)Acid resistance (International Organization for Standardization 195): Grade A

3)Alkali resistance (International Organization for Standardization 695): Grade B

The thickness of the glass ranges from 2.5mm to 15mm, and the maximum size can reach 4800mm×2440mm.

Bullet-proof glass

Layered with glass,PVB and polycarbonate,the kinetic energy of the bullet is convered into heat by the glass and interlayer.The Bullet-proof glass is widely used for museum artifacts,banks bulletproof,showcase,villa doors and windows etc.

Thickness:3-19mm(can be customized)

Max Size:4800*2440mm

Product Property:Tempered,Laminated

Packing & Delivery

* For small quantities, you can choose DHL or FedEx. It is safe and fast. We have a good rate withthem. Please contact us for

rates.

* Ocean Shipment is economical for big quantity.

* We can also help Custom clearance at destination port and deliver goods to your warehouse or office. And the cost is extra.

Company introduction

CNBM is a subsidiary of China National Building Materials Group Co., LTD., one of the World's top 500 enterprises CNBM line adopts oxygen combustion + electric boosting technology + platinum system technology with completely independent intellectual property rights. It is equipped with a melting furnace, tin bath, annealing furnace, and cold end cutting system suitable for the production of borosilicate glass. There are well-known international brands suitable for cutting and edging of borosilicate glass in Italy, and the latest tempering furnace in Finland. The company mainly produces borosilicate 3.3 heat-resistant glass and borosilicate 4.0 fire-resistant glass.

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: what is the price

- This problem you are online to ask, it seems that you do not understand the decoration, but also to undertake the decoration of KTV, it is not willing to tell you.

- Q: Composite foam cement insulation board, composite foam insulation board What is the level of fire insulation materials?

- Foam cement is inorganic, inorganic materials are noncombustible, non-flammable is the A-level, Christine to save more chewing Russian wedge fan blind but the foam cement water is too high, bearing the weight of bad, serious powder and rubbish is Of the ah

- Q: Building ceiling material fire rating

- Divided into four grades, non-flammable, flammable, flammable, flammable...

- Q: What are the general differences? The The

- Flame retardant grade PP, flame retardant PP, flame retardant PE, flame retardant PB, flame retardant PBT, flame retardant PC, flame retardant Burning PC / ABS alloy, and now there are still halogen flame retardant, halogen-free flame retardant research a lot, but the product stability and flame retardant effect has yet to be improved. Flame-retardant material testing methods are: commonly used flame-retardant material testing methods, including horizontal and vertical combustion, oxygen index method, NBS smoke box method, thermal analysis, cone calorimeter method. The simplest is the direct burning about, intuitive to see is from the fire to try Ding Bai shares of fat Karma mixed with the stem that is put out or continue to burn, burning time.

- Q: What are the fireproof materials?

- Water and wet cotton quilts

- Q: Today, see the Christine plant more broken off the German vouchers fan of the CCTV news channel reported that the district energy-saving transformation, the workers are more tense, the first use is to meet the A-class thermal insulation materials, later said to be polyurethane insulation board, and then use the fire A little moment on the smoke, and quickly took the fire machine, then smoke did not burn out, repeated several times did not dare how, this insulation board really fire? More

- Polyurethane insulation board can reach B level.

- Q: What is the fire insulation material

- Materials are: aluminum silicate fiber felt, inorganic mineral raw materials, perlite, glass fiber, ceramic fiber, mullite fiber, basalt fiber, high silicone fiber. Barrier insulation coating is a low thermal conductivity and high thermal resistance to achieve a thermal insulation coating. The most widely used barrier insulation insulation coating is a composite silicate insulation coating. This kind of coating is developed in the late 1980s, with different product names, such as composite magnesium aluminum silicate insulation coating, rare earth insulation coating, coated composite silicate insulation coating. It is made of inorganic and / or organic binder, insulation aggregate (such as sepiolite, vermiculite, perlite powder, etc.) and air entraining agent made of insulation coating. The performance requirements of such coatings can be found in GB / T-1998 "Silicate composite insulation coating". Composite silicate insulation coating Although the thermal conductivity is low, the cost is low, but the drying cycle is long, the impact resistance is weak, dry shrinkage, moisture absorption rate, low bond strength, poor decorative effect. This type of coating is currently used primarily for the casting of molds, tanks and pipes. This coating is currently not used for exterior insulation. In the future through the modified, is expected to be used for external wall insulation system.

- Q: Fire doors with fire insulation materials which?

- Perlite fire door core; glass magnesium fire door core

- Q: B1 refractory material refractory time long?

- At present, there are five main grades of fire protection: Class A: non-combustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger. In addition, according to different standards, the classification of fire materials are not the same: DIN4102: A1, A2, B1, B2, B3EN-1: A1, A2, B, C, D, E, FB1 fireproof materials, refractory time Look at the specific parts, see the following figure:

- Q: What are the materials for the kitchen ceiling that meet the fire protection requirements?

- There are now aluminum slab plate this material fire performance is relatively high. Waterproof gypsum board is also possible. Because all of these two materials all the accessories are made of green steel at the end of the end of the service, and these are not difficult to burn the material. These two materials in the fire are in line with the requirements of the waterproof. Many of the big public places are using this material.

Send your message to us

China hot selling glass high heat resistant ceramic glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches