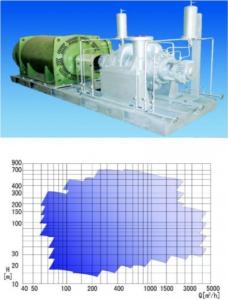

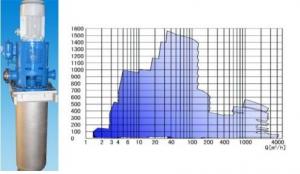

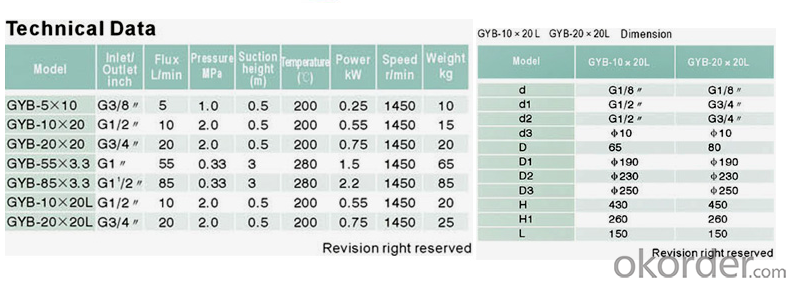

GYB Series High Temperature Industiry Oil Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GYB Series High Temperature Industiry Oil Pump

It is mainly used in plastic, rubber, mechanical, petrochemical and metallurgy industries, etc. It's modern design, high accuracy processing and high temperature resistant. Transmit medium: non-corrosion heavy and middle oil, industry oil and other oil whose Temperature≤280℃, Viscosity≤10°E

FAQ

FAQ

1 How can I get trained on CNBM products?

Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

2 Are your pumps cheaper than those of your competitors?

CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

3 Do you have self-priming pumps?

Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

- Q: My car oil pump pressure is low, engine oil alarm idling always ring, how to do?

- 1, check whether there is lack of oil.2, the condition is not very old, check the oil pressure sensor.3, sensor no problem, check the oil pump, see if the pump is not enough oil.The above problems are not possible, it may be a large gap in the bearing pad, the need for overhaul, it is recommended to overhaul the garage.

- Q: The working principle of gear type oil pump

- What are the working principles and characteristics of gear pumps? The gear pump is a volume type rotary pump, its working principle is: the gear pump has a pair of meshing gears, gear (wheel) fixed on the drive shaft and the shaft end of the gear pump extends out of the casing is driven by a prime mover, a gear pump (driven) installed on the other a shaft gear rotates, the gear pump, the liquid into the suction space along the suction pipe, along the upper and lower shell wall by two gears are respectively extruded into a discharge space (tooth and tooth before confluence), and then enter the pressure discharge tubing. The main features of gear pumps are compact structure, small size, light weight and low cost. Compared with other types of pumps, it has the disadvantages of low efficiency, large vibration, large noise and easy wear

- Q: What's the use of an oil pump in an automobile engine?

- When the engine is transported within pump oil lubrication parts inside the engine.

- Q: What's the use of the oil pump for motorcycles?

- Two stroke engine oil pump is regulated through cable, throttle in the middle line will be divided into two, one to one to the carburetor, the oil pump, the throttle fully closed, then adjust the speed nut oil pump on the cable, the cable to completely relax, this is the minimum amount of oil, but be careful not to too loose, when the twist of the throttle, engine oil pump should follow the action, there is a situation of oil pump through internal wear caused by excessive amount of oil used for many years, this situation can not be adjusted, only the replacement of oil pump.

- Q: What is the cause of engine oil alarm?

- Oil lamp alarm reason::1, the amount of oil is insufficient, so that the pump oil pump volume reduced, or because of air into the pump does not oil, resulting in lower oil pressure;2, the engine temperature is too high, easy to make oil thinning, from a large gap in the gap between the resulting oil pressure drop;3, when the oil pump parts damage or wear, assembly and other problems arise when the gap is too large, will cause the oil pump out of oil or the failure of the oil shortage;4, the crankshaft and large, small tile gap between the improper, too tight will make the oil pressure rise, too loose will make the oil pressure lower;5, the oil filter and oil suction disc plug will also reduce the oil pressure;6, the oil return valve damage or failure: if the main oil return valve spring fatigue softening or improper adjustment, the valve seat and the ball with the surface wear or dirt stuck and closed, the oil return amount will increase obviously, oil pressure of the main oil channel also decreased;7, improper selection of oil: if you use the wrong or improper selection of grades, the engine will run when the oil viscosity is too low and increase the leakage, thereby reducing the oil pressure;8, the oil pipe in the oil leakage, plug phenomenon.Only normal oil pressure can ensure that the oil is sent to all the friction parts of the engine, too high or too low will affect the normal operation of the engine, and even cause damage to engine parts. So, when the alarm lamp should be immediately shut down to find out the reasons, troubleshooting before it can continue to work.

- Q: Does the oil pump plug cause less oil?

- The oil pump plug will not cause any reduction in engine oil, which will only result in the following two results:1. oil pressure drop, oil flow decreases, the appearance of insufficient lubrication2., serious blockage will cause oil in the oil pipe can not flow, causing the normal operation of the components to form "dry grind", accelerating the wear rate of parts

- Q: How to check the motor oil pump oil supply is normal?

- In the premise of the normal amount of oil, usually need to check whether the oil pressure is normal (usually around 0.3MPa), if the oil pressure is low, usually the oil circuit, overflow valve failure or oil pump failure. After cleaning and adjusting the oil relief valve, the pressure is still low. The fault must be the oil pump failure.The effect of the oil pump is to press the engine oil to a certain pressure and force it to the surface of each part of the engine. If the oil pump is damaged or leaking, it is necessary to disassemble the oil pan, take out the oil pump and replace it, and clean or replace the oil pump inlet strainer at the same time.

- Q: I don't understand. How can the internal parts be bad, depend on it, it's depressing

- Pull in the water or burn the oil

- Q: Why does the engine oil pump need good timing?

- In the gasoline injection system, the fuel pump is an extremely critical component, once the fuel pump fails, the car will have a variety of adverse symptoms.First, the fuel pump failure, what problems will bring to the car?1, the engine can ignite, but can not start2 the fuel pump may leak inside3, excessive noise4, lack of motivation5. When you hesitate, speed upTwo, maintenance suggestions1. Most modern electric fuel pumps for automobiles are installed in the tank. Some vehicle access panels can be removed by replacing the pump without removing the fuel tank.2, tank fuel pumps are submerged in fuel to help them stay cool. The gas will destroy the fuel pump.3, fuel filter replacement fuel pump should be replaced4 fuel filter obstruction or electrical system driving fuel pump problems may cause symptoms similar to a failed fuel pump. The store confirms that the pump is in place before replacing it.5, gasoline is highly flammable. When replacing the fuel pump, the battery should be disconnected and proper safety procedures are provided to avoid fire and personal injury.

- Q: How do you install the pedal motor pump?

- Put the unit on the foundation with anchor bolts, between the base and the base, and use a pair of wedge pads.Release the axle shaft and place on the pump shaft and base with a level gauge. Adjust the level of the machine by adjusting the wedge pad and tighten the anchor bolts properly so as not to move around.Correct the concentricity of the pump shaft and the motor shaft, and allow the deviation of 0.1 mm on the outer circle of the axle shaft; two the clearance of the coupling plane shall be guaranteed 2~4 mm, and the clearance shall be uniform, and the tolerance shall be 0.3 millimeters.After connecting the pipeline and determining the direction of the motor rotation, then coupled with the coupling, and then check the concentricity of the shaft.In the actual test run 2~3 hours after the unit, for final inspection, if there is no adverse phenomenon, that the installation of qualified. Check the temperature and vibration of the bearing during the test run.During installation, all holes in the unit shall be covered to prevent debris from falling into the machine.In order to prevent the sundries from entering the pump, the filter shall be installed on the newly installed pipeline. The effective cross section shall be 2-3 times larger than the cross section of the suction pipe.However, the oil pump rarely fails, generally as long as the opening of the cylinder head, see more fresh oil or start the engine, there is oil jet, indicating the normal operation of the oil pump.

Send your message to us

GYB Series High Temperature Industiry Oil Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords