Sheets of Honeycomb Aluminum Louver Gutter Roof Aluminium Composite Panel 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Gutter Roof Aluminium Composite Panel 1100 3003

Alloy: 1050, 1060, 1100, 3003, 3004, 3005, 3105, 5005, 5052, 5083, 5754

2) Temper: Various status

3) Thickness: 0.3-150mm

4) Width: 300-1950mm

5) Length: Under9500mm/ Coil

6) Weight: 2.5-5.0 tons per coil

7) Dimensions and weight can be produced according to clients' specifications.

8) Inner Diameter: 505mm, 605mm

9) Packing: Export standard, wooden pallet.

10) Delivery time: 20 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Bright

14)Origin: China

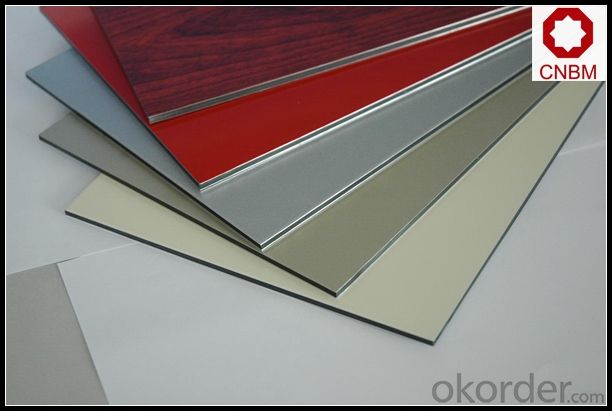

2. Application of Gutter Roof Aluminium Composite Panel 1100 3003

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Gutter Roof Aluminium Composite Panel 1100 3003

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

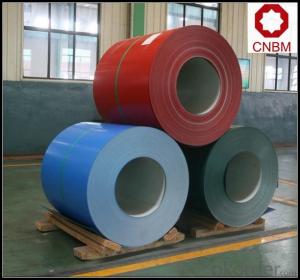

5. Image of Gutter Roof Aluminium Composite Panel 1100 3003

6. Package and shipping of Gutter Roof Aluminium Composite Panel 1100 3003

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, each with its own advantages and limitations. Some of the commonly used methods include: 1. Press Brake Bending: This method involves clamping the aluminum sheet between a punch and a die on a press brake machine. The sheet is then bent by applying force through the punch, which pushes against the die. Press brake bending is ideal for high-volume production and can achieve precise and consistent bends. 2. Roll Bending: Also known as a three-roll bending process, this method uses a set of three rollers to gradually bend the aluminum sheet into the desired shape. Roll bending is suitable for creating cylindrical or conical shapes and is often used in industries like automotive and aerospace. 3. Stretch Bending: In this method, the aluminum sheet is clamped at both ends while a stretching force is applied in the middle. The sheet is elongated and bent simultaneously, resulting in a curved shape. Stretch bending is commonly used for producing curved profiles with a smooth and uniform finish. 4. Heat Bending: By applying heat to the aluminum sheet, it becomes more pliable and can be easily bent into desired shapes. Heat bending is often performed using a heat gun or an oven to soften the metal, followed by manual or mechanical bending. This method is useful for creating complex and intricate shapes. 5. Incremental Bending: This method involves bending the aluminum sheet in multiple steps or increments, gradually increasing the bend angle with each step. Incremental bending allows for greater control over the bending process and is commonly used for forming U-shaped or V-shaped bends. 6. Roll Forming: In roll forming, the aluminum sheet is fed through a series of rollers, each gradually bending the sheet a little more. This continuous process is ideal for producing long and consistent bends, often used in the production of aluminum profiles and extrusions. It is worth noting that the choice of bending method depends on factors like the desired bend angle, the thickness and grade of the aluminum sheet, the required precision, and the volume of production.

- Q: I have a lot of old aluminum cake pans, coffee pots, pots and pans and various old nuts and bolts made of aluminum. Would it be worth it to scrap them? They really aren't usable for cooking anymore. They are clean.

- Aluminum is currently scrap priced at eighty cents per pound. If you have enough to justify the gasoline to go to a scrap yard, yes it is worth it. Your scrap will end up in Japan rather than in a landfill.

- Q: how to produce aluminium sheet circle?

- As for the process, you can use punch.. as for professional machines, for example, stationary press in open type, mechanical press/ single-point press. The material you say is neither big nor small, blanking…(cutting them into sheet circle you want) you can add an uncoiling if it’s coil stock: open-type inclinable press, four-point press,ect. It’s not certainly accurate) punch, oil press, double , four-column hydraulic (oil) press,etc. it needs about 315T,(estimated value, closed type single, blank material cutting (cutting into square ) 2, it contains sheet metal forming technology, crank press: 1: straight side two : 1, but the components you said is simple, only two steps.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Also what are some intersting facts about Aluminum? (the element) thanks 2 any 1 who answers =)

- Aluminum is a versatile material with vast applications in engineering, aerospace and automotive industries. Some of its desirable properties include lightweight (relative to steel) and high strength. The metal is however rarely used in its pure form, it is often alloyed with other elements such as Mg, Manganese, chromium, Titanium to fine tune its mechanical, chemical and or physical properties and tailor it to specific applications. However, in some applications other materials are preferred, for example, Magnesium, due to its higher strength to weight ratio is increasingly replacing Al in transmission casing of automobiles. Also, Compacted Graphite cast Iron is preferred in engine blocks because of its superior strength at high tempreatures, dimensional stability and wear resistance. Auto engines work at very tempreatures and alloys that are capable of withstanding high pressures while maintaining stability are critical. CGCI performs better than Al in this situation. Al alloys remains an important engineering materials though.

- Q: Can aluminum sheets be anodized without affecting their dimensions?

- Aluminum sheets can undergo anodization without significantly impacting their dimensions. Anodization is an electrochemical procedure that produces a protective oxide layer on the aluminum's surface, enhancing its resistance to corrosion and durability. To perform anodization, the aluminum sheet is immersed in an acidic solution while an electric current is passed through it. This causes the aluminum to oxidize, resulting in the formation of an aluminum oxide layer on the surface. Throughout the anodization process, the aluminum oxide layer grows both inward into the metal and on the surface. The growth of the oxide layer can be precisely controlled by adjusting the duration of the anodization process to achieve the desired thickness. Consequently, the dimensional changes induced by anodization are minimal and can be easily accommodated during the design phase. Nevertheless, it is worth noting that anodization can lead to a slight increase in the thickness of the aluminum sheet. This is due to the growth of the oxide layer on the surface. Typically, the increase in thickness is approximately 50% of the overall thickness of the oxide layer. For instance, if the desired oxide layer thickness is 10 micrometers, the resulting increase in sheet thickness would be approximately 5 micrometers. In conclusion, anodizing aluminum sheets can result in a slight increase in thickness, but the dimensional changes are negligible and can be accurately predicted and taken into account during the design phase. Anodization is a widely used and effective method for enhancing the properties of aluminum sheets without significantly altering their dimensions.

- Q: What is the thermal expansion coefficient of aluminum sheets?

- The thermal expansion coefficient of aluminum sheets typically ranges from 22 to 24 x 10^-6 per degree Celsius.

- Q: This question asks for the duration aluminum sheets can last and how their lifespan compares to other materials.

- <p>The lifespan of aluminum sheets can vary depending on the environment and usage, but generally, they can last for several decades with proper care and maintenance. Aluminum's resistance to corrosion and weathering makes it a durable choice. Compared to other materials, aluminum is more durable than wood and many plastics, but it may not last as long as some high-quality stainless steels or certain types of stone. It's also lighter than steel, making it a popular choice for construction and manufacturing applications where weight is a concern.</p>

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Yes, aluminum sheets can be used for kitchen backsplashes. Aluminum is a durable and lightweight material that is resistant to moisture and stains, making it a suitable choice for kitchen backsplashes. Additionally, aluminum sheets are easy to clean and maintain, making them a practical option for any kitchen.

Send your message to us

Sheets of Honeycomb Aluminum Louver Gutter Roof Aluminium Composite Panel 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords