Grey Bronze Aluminum Coil for Metal Roofing 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

1.Structure of Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

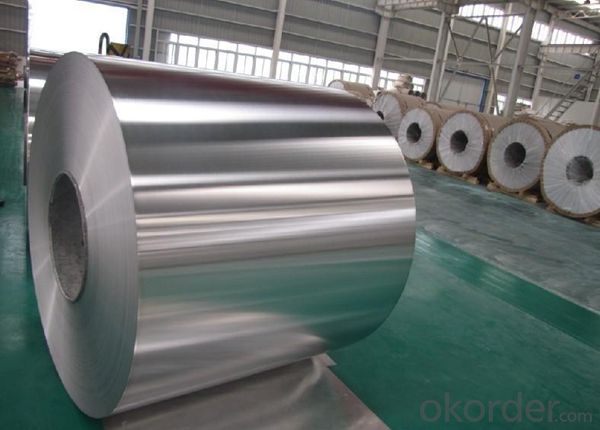

3. Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX Images

4.Specification of Aluminum Coil for Metal Roofing 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: It's time for a new bike and I don't know enough about the pros and cons of aluminum vs. carbon fiber. I can get a low-end carbon bike or a high-end aluminum for about the same price, so the budget is not really a major issue. Any opinions would be appreciated.

- Just a little personal story here. I recently bought a new old stock Carbon Giant TCR Limited at a great price, did some wheel upgrades and the like then took it out for a ride. The difference between that bike and my Colnago Aluminum Dream (still have it) was amazing. The whole ride quality, smoothness and climbing ability of the CF bike was supierior to that of the Colnago. Or was it just the novelty of the newness? Sure the two have different geometries and gearing but I feel so much more comfortable on the CF giant for long (over 50 mile) rides then the Al. Colnago. Test ride them both, you'll see.

- Q: Are there any restrictions on the coil surface quality of aluminum coils?

- Aluminum coils have specific limitations when it comes to their surface quality. The quality of the coil's surface is crucial as it impacts both the overall performance and appearance of the final product. Various restrictions are in place to maintain the coil's surface quality, including the following: 1. Surface defects: Visible imperfections like scratches, pits, dents, or cracks should not be present on aluminum coils. These defects can hinder the coil's functionality and affect the aesthetic appeal of the end product. 2. Surface smoothness: The surface of aluminum coils should possess a uniform and smooth finish. Excessive roughness can hinder the adhesion of coatings or paints and affect the coil's ability to be shaped as desired. 3. Surface cleanliness: Aluminum coils should be devoid of contaminants such as dirt, oil, or grease. These impurities can interfere with subsequent processes like painting, coating, or bonding, and impact the overall performance of the coil. 4. Surface oxidation: Aluminum is prone to oxidation, resulting in the formation of a thin oxide layer on the surface. While a certain level of oxidation is acceptable, excessive oxidation can hinder the adhesion of coatings or paints and affect the coil's resistance to corrosion. 5. Surface flatness: Aluminum coils should possess a flat and even surface. Any waviness or unevenness can cause complications during subsequent manufacturing processes like stamping, bending, or rolling. Maintaining these restrictions on coil surface quality is essential to ensure that aluminum coils meet the desired specifications and can be effectively utilized in various industries, including automotive, construction, packaging, and electrical.

- Q: Is it possible to utilize aluminum coils for the storage of food items?

- <p>Yes, aluminum coils can be used to store foodstuffs, particularly in the form of aluminum foil. Aluminum foil is a common food storage material due to its properties such as being lightweight, flexible, and providing a barrier against air and moisture. It is often used for wrapping food for cooking, freezing, or preserving. However, it's important to ensure that the aluminum does not react with the food, especially acidic foods, as this could lead to contamination. Additionally, it's not recommended for long-term storage as it does not provide a complete seal or barrier against all contaminants.</p>

- Q: What are the advantages of using aluminum coils in HVAC systems?

- There are several advantages of using aluminum coils in HVAC systems. Firstly, aluminum coils are significantly lighter compared to traditional copper coils. This makes them easier to handle and install, reducing the overall labor and transportation costs. Additionally, the lighter weight of aluminum coils puts less stress on the HVAC system, resulting in less wear and tear over time. Another advantage of aluminum coils is their superior resistance to corrosion. Aluminum is naturally resistant to rust and oxidation, which can prolong the lifespan of the coils and enhance the overall durability of the HVAC system. This resistance to corrosion also helps maintain the efficiency of the system, as the coils remain clean and free from clogs caused by debris buildup. Moreover, aluminum coils have excellent heat transfer properties. They can efficiently absorb and release heat, allowing the HVAC system to cool or heat the air more effectively. This improved heat transfer efficiency can result in energy savings and reduced operating costs, as the system requires less energy to achieve the desired temperature. Furthermore, aluminum coils are more environmentally friendly compared to copper coils. Aluminum is a highly recyclable material, and using aluminum coils can contribute to reducing waste and conserving resources. Additionally, the process of manufacturing aluminum coils requires less energy and produces fewer greenhouse gas emissions, making it a more sustainable choice for HVAC systems. In summary, the advantages of using aluminum coils in HVAC systems include lighter weight, corrosion resistance, superior heat transfer properties, energy efficiency, and environmental sustainability. These benefits make aluminum coils a preferred choice for many HVAC professionals and homeowners alike.

- Q: What are the common testing methods for aluminum coils?

- There are several common testing methods for aluminum coils that are used to ensure their quality and performance. These methods include: 1. Visual inspection: This involves a thorough examination of the coils for any visible defects such as dents, scratches, or surface irregularities. Visual inspection is a basic and initial step in the testing process. 2. Dimensional measurement: This method involves measuring the dimensions of the aluminum coils to ensure they meet the specified requirements. This includes measuring the length, width, and thickness of the coils. 3. Tensile testing: Tensile testing is performed to assess the mechanical properties of the aluminum coils, such as their strength and elasticity. This test involves applying a tensile force to a sample of the coil until it breaks or deforms, allowing for the determination of its tensile strength. 4. Hardness testing: The hardness of aluminum coils is an important factor in determining their suitability for specific applications. Various hardness testing methods, such as Rockwell or Brinell hardness tests, can be used to measure the resistance of the coil's surface to indentation or scratching. 5. Chemical composition analysis: This method involves analyzing the chemical composition of the aluminum coil to ensure it meets the required specifications. Common techniques used for this analysis include spectroscopy or X-ray fluorescence (XRF) analysis. 6. Corrosion resistance testing: Aluminum coils are often exposed to harsh environmental conditions, so assessing their resistance to corrosion is crucial. This can be done through various tests like salt spray testing or electrochemical impedance spectroscopy (EIS) to determine the coil's ability to withstand corrosion. 7. Coating quality assessment: If the aluminum coil is coated with a protective layer, testing methods such as adhesion testing, coating thickness measurement, or impact resistance testing can be used to ensure the quality and durability of the coating. These are some of the most common testing methods employed for aluminum coils. By conducting these tests, manufacturers can ensure that the coils meet the required standards and perform optimally in their intended applications.

- Q: This question asks about the maintenance difficulty of aluminum coils.

- <p>Aluminum coils are relatively easy to maintain. They are resistant to corrosion and do not require frequent cleaning or special treatments. Regular inspection for any physical damage or signs of wear is sufficient. However, it's important to keep them dry and clean to prevent any potential issues. For specific applications, such as in HVAC systems, regular cleaning may be necessary to ensure optimal performance. Overall, maintenance is minimal compared to other materials.</p>

- Q: What are the different types of surface defect classifications for aluminum coils?

- There are several types of surface defect classifications for aluminum coils. These classifications are used to categorize and identify various imperfections that can occur on the surface of aluminum coils during the manufacturing process. Some common types of surface defects include: 1. Scratches: These are linear marks or grooves on the surface of the aluminum coil. Scratches can vary in depth and length and are typically caused by mechanical friction or handling during production or transportation. 2. Streaks: Streaks are discolorations or lines that appear on the surface of the coil. They are often caused by uneven coating or impurities in the aluminum material. 3. Dents: Dents are depressions or distortions on the surface of the coil. They can be caused by mishandling, impact, or improper storage of the coils. 4. Pitting: Pitting refers to the presence of small, localized holes or craters on the coil surface. It is often caused by the corrosion of the aluminum, exposure to aggressive environments, or improper surface treatment. 5. Surface contamination: This classification includes any foreign substances or contaminants that are present on the surface of the aluminum coil. Examples of surface contaminants can include oil, dirt, dust, or residues from the manufacturing process. 6. Oxide films: Oxide films are thin layers of aluminum oxide that can form on the surface of the coil. These films can vary in thickness and appearance and are often a result of exposure to air or moisture. It is important to classify and identify these surface defects accurately as they can affect the quality and performance of the aluminum coils. Manufacturers and customers use these classifications to determine the acceptability of the coils and make decisions regarding their usability and potential treatment or repair.

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

- Q: The user is asking if it's possible to purchase recycled aluminum coil through online platforms.

- <p>Yes, you can buy recycled aluminum coil online. Many online marketplaces and specialized metal supply websites offer a variety of aluminum coils, including recycled ones. You can search for suppliers on platforms like Alibaba, Amazon, or industry-specific B2B websites. Be sure to check the supplier's reputation, the quality of the recycled aluminum, and the specifications to ensure it meets your requirements.</p>

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a safe and commonly used material for food storage due to its non-reactive properties and resistance to corrosion, making it suitable for maintaining food quality and preventing contamination.

Send your message to us

Grey Bronze Aluminum Coil for Metal Roofing 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords