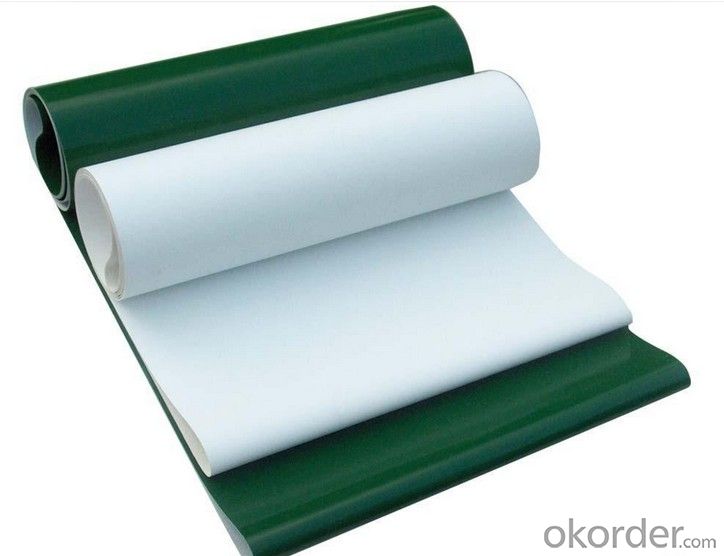

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

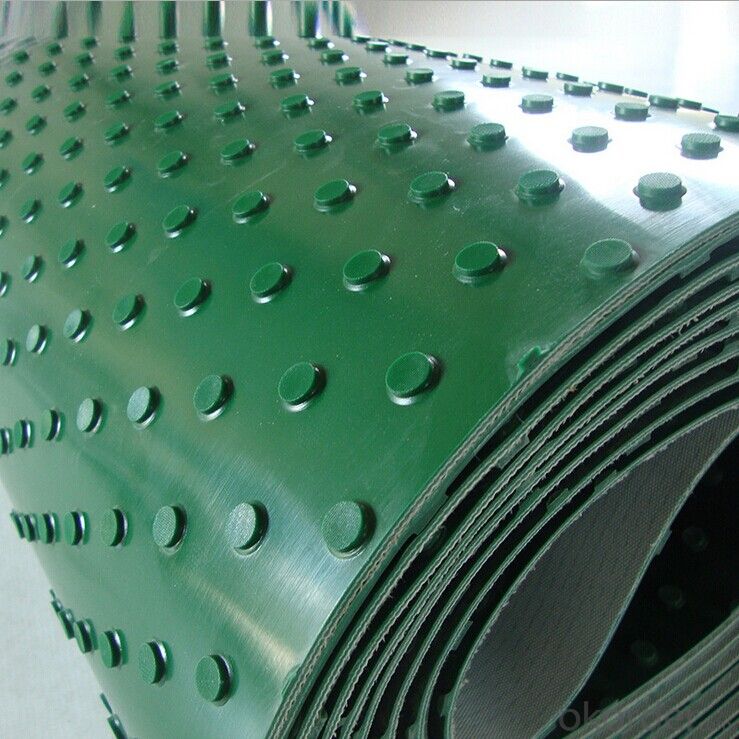

Descriptions of PVC Conveyor Belt

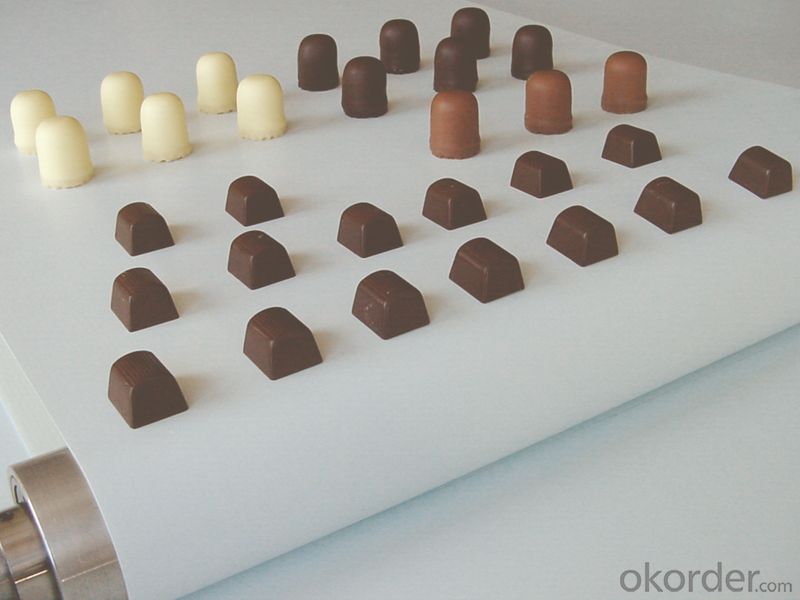

PVC conveyor belt for Conveyance and production assembly lines in the areas of food,beverage, cigarettes,tobacco,airportetc.

Thickness: 2.0mm

Width: Width of the largest production 3 meter

Length: According to the customer request production. Regular length is 100 meters.

Color: White, green, black etc.

Can be produced as customers' requirements, such as thickness, width and length.

Features of PVC Conveyor Belt

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise

* Working temperature ranges from -10 to 80Deg.C

It adopts high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC&PU. We introduce the key technologies and equipment from the United Kingdom Specialization (Fenner) Corporation in the production.

Applications of PVC conveyor belt

Widely used in the Conveyance and production assembly lines in the areas of airports, postal automation, parcel handling, treadmills, packaging/wrapping, cigarettes,tobacco,leather, foodstuffs, drinks, medicine,chemical,tyre , electronics, pharmaceutical, printing,papermaking, wood, stone/marble, entertainment industry and fishery industry etc.

Pictures of PVC Conveyor Belt

RFQ:

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC treadmill conveyor belt, you could make an Inquiry in

okorder.com. Okorder.com provides you the products with best price and quality!

- Q: Classification of other rubber sheets of wear-resistant rubber plates

- The wear-resistant rubber sheet used in industry is divided into flat wear-resistant plywood, rhombus wear-resistant plywood and ceramic wear-resistant plywood according to the different types of rubber sheets. At present, a new type of RIT wear-resistant rubber sheet with semi vulcanized layer and chemical reaction with cold vulcanizing glue is more commonly used.As with other wear-resistant plywood, RIT wear-resistant rubber sheet is also divided into RIT flat wear-resistant plywood, RIT Ling wear-resistant plywood and RIT ceramic wear-resistant plywood.

- Q: Process for producing rubber products

- In the production process of rubber products, the process of making various shapes and sizes is made by using a calender or an extruder, which is called forming. Forming methods are1. rolling formingThe utility model is suitable for making simple sheet and plate shaped articles. It is a method of pressing compound rubber into a certain shape and a certain size of film by calender. It is called calendering forming. Some rubber products, such as tires, adhesive tape, hose and other textile fiber materials, must be coated with a thin layer of glue on the fiber, also known as glue or glue, the process of gluing is generally completed on the calender. Fiber material needs drying and dipping drying before calendering. The purpose is to reduce moisture content of fiber material, avoid evaporation and foaming, and increase the temperature of fiber material, so as to ensure the quality of calendering process. Dipping is a necessary process before cementing. The purpose is to improve the bonding property of fiber and rubber.2. extrusion moldingFor more complex rubber products, such as tyres, tread, hose, and wire surface coating, shall be made by extrusion molding. It is a method of continuous molding with a certain plastic compound into the extruder's hopper, the extrusion of the screw under the internal screw, and through a variety of dies, also known as the templates. Before extrusion, the material must be preheated to make the material soft and easy to extrude so as to obtain a smooth and accurate rubber product.3. moldingIt can also be used to make some rubber products with complex shapes, such as leather bowl and sealing ring. The rubber material is placed in the mold and shaped by heating.

- Q: UV glue can glue rubber products?

- If you want to completely recover, do not see the crack, in addition to professional factories, individuals can not reach this technology for the time being

- Q: What material is the rubber used in the tires?

- The tyre is known, usually made of rubber materials, a solid tire and pneumatic tire parts, pneumatic tyre and tubeless tire composed by.

- Q: What is rubber damping material?

- Butyl rubber, butyl bromide and butyl chloride are the main ones!! Need to design, sell rubber products, can find me!

- Q: How to improve the hardness of rubber?

- Increasing the degree of crosslinking (increasing the dosage of vulcanizing agent and prolonging the curing time properly);Increase the dosage of reinforcing agent, or choose reinforcing agent with high structure and large specific surface area;Hardening resin, high styrene and other hardening agent;

- Q: Half finished rubber film surface white is going on

- Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: How can there be a crack in the rubber ring?

- Problems in production:1) formulation design, oil or resin less material or caused by excessive or high temperature, poor liquidity and other reasons!2) when manufacturing, the product appears the hole which the exhaust is not good3) the raw material is too thick during production, and cracks are also caused.

- Q: How to improve the aging resistance of rubber?

- The shorter the light wave, the greater the energy, the greater the damage to the rubber. Ultraviolet not only directly caused the breakage and crosslinking rubber, rubber surface is also resillage guttacontent especially high rubber is more obvious this is the light splitting outer rubber particles (black rubber particles and colored rubber particles).

- Q: What is the rubber composition and function of the airplane tyres?

- Ethylene propylene rubber and ethylene propylene rubber are synthesized with ethylene and propylene as main raw materials. They are resistant to aging, electrical insulation and ozone resistance. Ethylene propylene rubber can be filled with oil and filled with carbon black. The price of the product is low, and the chemical stability of the ethylene propylene rubber is good. The abrasion resistance, elasticity, oil resistance and the proximity of styrene butadiene rubber are close. Ethylene propylene rubber is widely used. It can be used as tyre, sidewall, rubber strip and inner tube, as well as parts of automobile. It can also be used as wire, cable sheath and high voltage and extra high voltage insulating material. Can also manufacture rubber shoes, sanitary products and other light colored products. It is a chloroprene rubber as the main raw material, made by homopolymerization or copolymerization of small amounts of other. Such as high tensile strength, heat resistance, light resistance, aging resistance and oil resistance properties are superior to natural rubber, styrene butadiene rubber, butadiene rubber. It has a good flame resistance and excellent resistance to burning, its chemical stability is high, water resistance is good. Chloroprene rubber is electrical insulation, cold resistant performance is poor, rubber is not stable in storage. Neoprene is widely used, such as the manufacture of transport belts and belts, wires and cables, and the manufacture of oil resistant hoses, gaskets, and chemical resistant equipment linings.

Send your message to us

Green PVC Conveyor Belt White PU Conveyor Belt In Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords