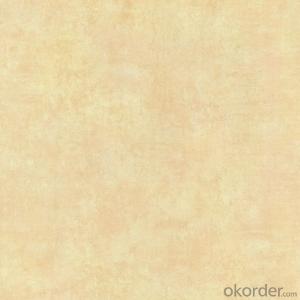

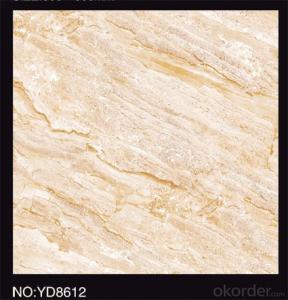

Glazed Porcelain Floor Tile 600x600mm CMAX-S6627

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

Glazed Porcelain Tile CMAX-A6012 is one of the popular colors in the present market. Just like other series, it could be used for interior floor and wall for apartment, villa, as well as other public areas, due to its unique antique feel image and texture. The glazed porcelain floor tile is wildly used in Europe, North America and Middle East.

Product Features

Glazed Porcelain Floor Tile

Grade AAA available only

Mainly the basic size is 600*600mm, which could be cut into 30*60mm, 30*30mm, 15*60mm.

Strict quality control system for monitoring water absorption rate, color shade, deformation, anti-pollution, slip-resistance, abrasion resistance as well as packing.

More competitive prices in China supplying market

Standard export packing: Pater Carton+ Wooden Pallet

Fast production arrangement

OEM service could be offered based on the actual requirement

Marketing support on samples, catalogues as well as carton designing

Professional sales team for the whole purchasing process.

Product Specification

Tile Type: Glazed Porcelain Floor Tile

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 《0.5%

Breaking Strength: 》 1300 N

Rupture Modulus: 》40 MPa

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.5%

Edge Straightness: ±0.5%

Wearing Strength: 《1600 mm3

Slip Resistance: 》 0.5

Resistance to Chemical: Class UA

Resistance to Staining: Class 3.

Packing Information (For 27.5 Tons heavy 20’Fcl)

For 600x600mm, 4pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6m2/20’Fcl

For 300x600mm, 8pcs/Ctn, 40 Ctns/Pallet, 840 Ctns/20’Fcl, 1209.6 m2/20’Fcl

Production Line & Package

FAQ

1. For Glazed Porcelain Floor Tile, what is the difference from polished porcelain tile?

—— For Glazed Porcelain Floor Tile, there is a special glaze layer on the tile surface, which makes the surface feel matt or rough, while the surface of polished porcelain tile is glossy and smooth.

2. Could you put some samples in the container of our orders?

—— Yes. We’d like to offer free samples in the containers to our clients, with a certain quantity of different models.

3. Could we be your exclusive agent in our country?

—— Possibly. For some countries we are hoping to find a proper partner in working market together. For sure we need to have a good talking for the details.

- Q: the bathroom at work has lenulium sheet. I slip when it rains, b cos it is wet. I want to replace home carpeting with tiles or vynal. which one is less slippery? thanks

- ther in none slip for both products. shop around

- Q: I live in an apartment and ive never had floor tiles like these.There is concrete underneath but I think these are ceramic tiles on top.I have no clue what to use to bring back the shine.Any suggestions would be helpful

- Elbow grease.

- Q: Ceramic tile a square with how much, how to buy ceramic tile, the price is how much

- The price of ceramic tile by the brand, type, specifications, freight, local prices and the impact of wage levels, are generally concentrated in the 45-70 yuan between the specific you need to go to the local building materials market to ask and contrast. As for the amount of paste a square, the size of the tile directly by the size of the construction technology and the impact of the loss rate, under normal circumstances if the 600 * 600MM below the tiles, the general amount per square in about 3.5KG, greater than 600 * 600MM Then each square needs about 5KG. The above amount is in the case of the formation of the base surface, if the base is not flat recommended first mortar leveling, and then use the tile glue to paste.

- Q: the kitchen is pretty spacious, but is it possible to put tiles on top of wood?

- vinyl tiles? or ceramic tiles. The answer is yes. You would have to prepare the floor and buy the materials.It can be done. Get a professional to do it. The sides and edges can get iffy and you need a special saw for the tiles, it is not easy but the pros can do it really fast and even,as it is pretty hard to just get the floor prepared. Tile looking floor panels are faster to put in than ceramic tiles..

- Q: Home decoration with what tiles better

- Research a lot of tiles, online tattoo comments brand tiles are: the famous Dongpeng many Shandong Zibo OEM turn, just advertising to do bright! Shop out is not smooth! Marco Polo also has a lot of branded brick! Comments that gold pottery is rubbish, poor service! Commented that the generals serious uneven, I really experience from the physical shop what is the stone arch bridge! Commented that Samit was serious in the drum, I also deliberately in the physical store is indeed the case, I have been set and back! Online comment Nobel is not flat, this I did not see! Gold rudder is expensive! ... ... I want to buy a brand name of the number of friends to the brand Tucao finished, not scolded like only Hongyu and crown beads, so I deliberately went to the two stores looked, really fabulous, but hit Hongyu sound Crisp, may be good bricks, but the price is very expensive, in our reputation there is no crown beads, so into the crown beads shop, but also very expensive. I deliberately poured the floor of the small floor of the brick, actually did not infiltrate a minute, so I decided to buy beads, but the price seems to be as expensive as Hongyu, only buy crown beads tiles and toilet bricks, to save money, kitchen brick to buy A miscellaneous brand. Hope that the crown will not let me down!

- Q: 16 by 16 tiles

- Tile labor varies a bit from area to area, but you can figure in the $7 a s/f range for basic labor , thin set, grout and 1/2 cement board , which is generally need when installing over the common wood sub floors. Tile isn t figured in this price since a plain , average or discontinued tile can go from $1 a s/f to a very nice tile in that size at 4$ a s/f Extras such as rip out/ disposal and any floor prep isn t included either. Any questions you can e mail me through my avatar.. GL

- Q: Hello! I currently have a 3 season sunroom addition on the back of my home that has been stripped down to the wood. I recently saw a 4 season sunroom that had tile down and needless to say, I fell in love with it! I am thinking about putting tile down in there but am worried about the weather...I live in Minnesota where it gets very cold...and that room is not heated in the winter. Would I have problems with the tile cracking? Or does anyone know of an alternative way to get a tile-looking floor without having to worry the temperature changes??

- Hi, In the UK we have a floor covering which is similar to the wood effect laminate floor, it locks together and looks amazingly like 9x9 tiles. I put it in my bathroom and it is not as cold as tiles to the bare feet. It is a wood/paper based product but is waterproof for the normal house hold duty. I assume that the Minnesota winter will not make it too cold. Use a styrefoam underlay 2mm thick to prevent heat loss. this is a do it yourself job if you are handy with a saw, We know it as TILE LOK

- Q: It‘s something I really want to do, I find myself longing for it often. Tile or ceramic, not sure yet. But, my house is 1485 square feet and I‘m wondering if anyone has a ball park estimate for what price range I‘m looking at! I know different variables like tile vs ceramic, etc, but just looking for a range if anyone can help.Thanks!

- Very expensive when you consider $4-$5 or more per sq foot for installation costs, plus the cost of the tile itself. Tile , whether ceramic, slate, marble, etc., will require a cement backer board [$1+ per sq ft], mastic mortar[ $.50+ per sq ft], grout, sealer, etc.. For 1500 sq ft this will add up fast, even if you do the labor yourself. Consider resale as well. Some option to consider might also include under-tile floor heat at least in the bathrooms, usually well worth the expense. I personally share your likes as far as tile vs carpeting, but future home-buyers might like a more rounded choice, such as hardwood flooring. If you have ever stood on a concrete floor for long periods [painful on the back and joints], this is what a whole house of tile will feel like. Hardwood flooring has a little cushion to it.

- Q: we‘re moving into a new home that has hot pink ceremic tile as the kitchen counter top and back splash. Can we paint over the tile or do we need to remove the tile and start over with a new counter top.

- Don't do it. Remove the old tile and start over. You have to live with this for a long time (I'm assuming you own). Don't live with something thats not what you want. Even if you think down the road at resale value....a painted tile (I don't think you can even do it) would be a real black mark against the property.

- Q: Right now the wall is horrible paneling, I am drywalling the house, but I really want one wall tiled with granite tiles. Would it be better to do this on the paneling or drywall? Will it be too heavy and rip the wall down? Is there a safe way to do this?

- You could put hardybacker up right over the paneling, but personally I would remove the paneling first and then install the hardybacker. The backerboard will not absorb the moisture from the thinset or mastic like drywall and the paneling probably has a finish on it that won't bond very well. Are you meaning slate, as I have never seen anyone do a wall in granite but I suppose it could be done A slate accent wall is very reasonably priced at about 2.00 per foot, easy to do and when sealed with high gloss wet look sealer, can be quite impressive

Send your message to us

Glazed Porcelain Floor Tile 600x600mm CMAX-S6627

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115.2

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches