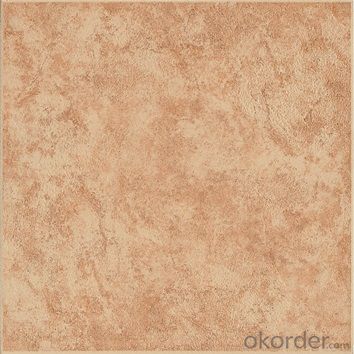

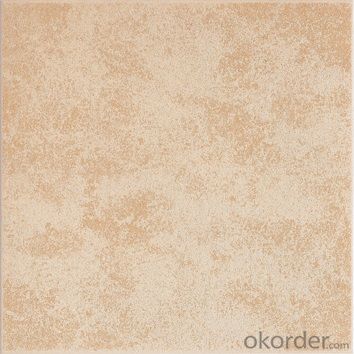

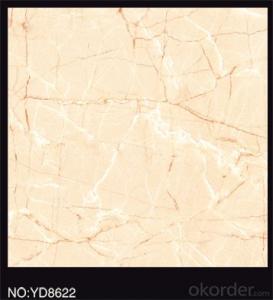

Glazed Floor Tile 300*300mm Item No. CMAX3A435

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1683 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Brief Introduction

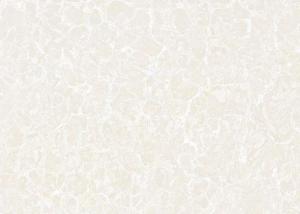

Glazed Floor Tile 300*300mm, CMAX3A435 is one of the popular models of 300*300 mm glazed floor tile, which is wildly used for floor of kitchen and bathroom as well as balcony and bedroom. These tiles could create an antique feel of classic European life, just like living in the old times of nature and pastoral life.

Product Features

Glazed Floor Tile

Only Grade AAA available

Strict control on glazing, water absorption rate as well as color shade and straigtness

Competitive price

Standard export packing: Pater Carton+ Wooden Pallet

Fast delivery

OEM service could be offered

Marketing support on samples, catalogues as well as carton designing

Professional sales team for product, document and schedule of importing and exporting.

Product Specification

Tile Type: Dry-Pressed Tile, Silk Printing Glazed Surface

Quality standard: GB/T4100-2006, ISO13006, ISO9001

Water Absorption Rate: 3% -- 6%

Length and Width Tolerance: ±0.1%

Surface Smoothness: ±0.15%

Edge Straightness: ±0.15%

Packing Information (For 27.5 Tons heavy 20’Fcl)

11pcs/Ctn, 18.5kg/Ctn,1472Ctns/20’Fcl, 1457.28m2/20’Fcl

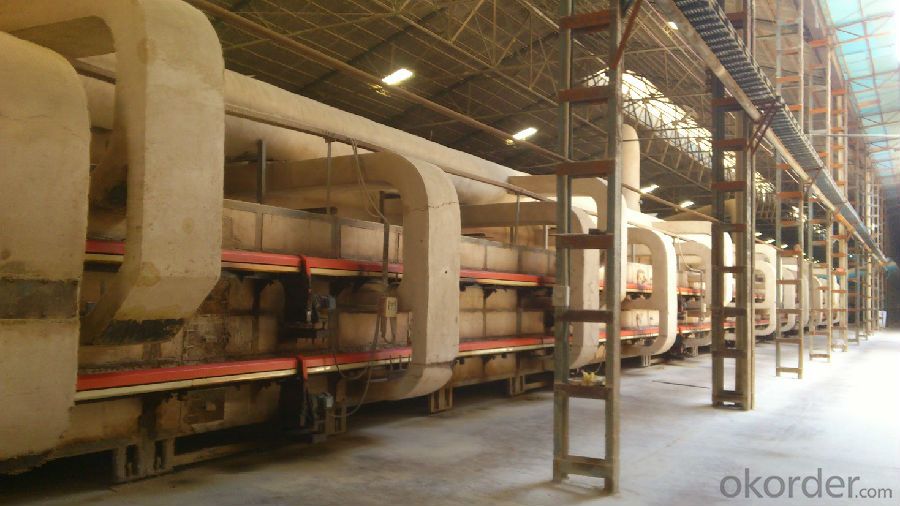

Production Line & Package

FAQ

1. Could you company supply polished porcelain tile?

—— Yes. We could supply various kinds of polished porcelain tile, with size 60*60, 80*80, 100*100 and 60*120.

2. What is the MOQ for this tile?

—— Normally the MOQ is one 20’ container. For some special model, if its production is not arranged frequently, the MOQ is 5 containers.

3. For Glazed Floor Tile, is the 40*40 available?

—— Yes, 40*40 is available. Based on the actual market demand, we could also supply 45*45 and 50*50 accordingly.

4. Can we use the carton with our own design and brand name?

—— Yes. Normally we go with Neutral Carton or our Carton with our CMAX brand name. But for carton of client’s own design, the MOQ for one size is 5 containers, due to the carton factory can’t arrange production if quantity is below 5000 pcs.

- Q: If you can tile on top do i need to prepare the old tile surface?

- Yes you most definitely can if the tile is down solid and is clean from grease and dirt etc.... You ll need to check exterior doors to make sure they ll open..A special modified thin set is strongly recommended and allow a minimum of 2 days (long if possible) before any foot traffic goes on the tile.This because there is no where for the thin set moisture to go and you don t want to break the bond.. No special prep work is needed aside from thoroughly cleaning the tile and grout. Don t set grout joint over grout joint if you have the same size tile.. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: The tile guy just wants to add fresh grout, but doesn‘t that wood need to be replaced too. Help the work is to be done in 2 days.

- Is this tile in the shower? If so you need to pull up the tile and have a tile membrane installed on the floor to waterproof the area. If it is outside the shower the wood should be treated wood or it will bulge and crack the tile in the future. If it is treated wood then you can just lay replacement tile down. If they know what they are doing and have the appropriate help, then any tile job can be done in one day.

- Q: I want to lay ceramic tile in the entry way of my townhome. It‘s about 80 sq ft. The house originally came with a generic white vinyl flooring that I swear is officially a part of the concrete slab it lays on. Because it is so firmly attached (no bubbles, no visible defects of any kind) would it be possible to lay the ceramic tiles over the vinyl? I honestly think it‘s going to take more time to rip up that flooring (and the glue that keeps it down) than it will laying the tile. Thoughts? Thanks!

- Go to a Tile Store. They now have Ceramic Tile which can be put on top of other flooring as long as the floor is level. Some of these Tiles can be snapped together. No Mud, no Grout.They look wonderful.

- Q: OK here is my problem. I want to switch my bath tub to an all-tile shower and wonder how to do it. So far the tile were set onto a cement board that was itself put on top of the drywall. I am wondering if this is a common thing. From all my research, it looks like tile should be on the cement board, but there is no use for extra drywall behind it. It actually makes things tougher because you need some sort of corner tile instead of normal bullnose since the cement board and the rest of the wall are not at the same level.My second question is: is there an order to do all this i.e. should I make the shower pan (sort of rubber sheet filled with cement), before or after I install the cement board on the wall. Is there a specific angle used for the drain?Thanks in advance for all your tips.

- take off all tile and wallboard down to the studs.move all plumbing,use a pvc liner which bolts to the drain flange.when nailing the liner to the studs run the liner about a foot up the wall.no fastners 9in or lower or it will leak.put up your concrete board,remember no fastners 9in or lower concrete will hold the bottom.form a curb using 2x6s run the liner in the middle of the form. use a 2x6 braced against the back wall inside the shower to hold the form inside the shower. fill with concrete on both sides.i use quickcrete sand topping mix.let the curb dry for 24 hrs.pull the form.now pour concrete inside the curb. your pan should have a pitch of 1/4 in.for every foot from the drain.let dry again for 24 hrs.do not use wall mastic as adhesive for the tile, use mortar.i also use hydroguard 1 from dal-tile in the corners and seams.you can brush it on.now your ready to tile.if you dont have any bullnose ,you can use a metal trim. i use dal-tile #a100.get a mosiac tile for the floor so it will wrap the pitch of the floor.use a sanded grout on the floor.you can butt the tile joints on the wall but if you do, use a nonsanded grout.silicone all corners.putting in a custom shower is one of the hardest thing you can do in your home,

- Q: I am looking to either repair my flat tile roof or replace it for a shingle roof.

- there are no roofs in florida.

- Q: I am looking at putting the self stick vinyl tiles in my new addition. It has a concrete floor and I was wondering if the vinyl will have a hard time sticking to the concrete. Do I need some type of sub-floor? I am wondering this mainly because we live in iowa were is can get pretty cold in the winter and I didn‘t know if that would affect the stickyness.

- Self stick tiles commonly loosen from subfloors, concrete or wood. They can be installed successfully over concrete but it is absolutely vital that your concrete be smooth and very, very clean. If you are concerned about adhesion it would be wiser to use glue down vinyl tiles which aren't much more expensive, rather than build a very expensive wooden subfloor which wouldn't guarantee the integrity of peel and stick tiles.

- Q: why is waterproofing done before grouting?why do we need to let the mortar/adhesive dry before grouting?

- You should use special green board for the shower. It is water resistant not water proof. This gives the best base for the tiles. You should leave the adhesive set up totally before grouting because the gases that are in the glue need a place to go. This includes thin set mortar because of the water vapor it out gases. Good luck

- Q: I have old, crumbly tile as a subfloor in my apartment. I recently put in vinyl flooring when I took my carpeting out. It now looks as if this tile (wood-like vinyl planks) are taking the shape of the subfloor, which was not perfectly even. I don‘t like that I see shadows of peaks and valleys in the new flooring in certain light. It also doesn‘t feel even when I walk on it barefoot, but I‘m extremely particular.1. Should a coating have been applied to even-out the old tile BEFORE the vinyl flooing was installed? (the company didn‘t want to take these up as they felt it was asbestos. the worker who installed the new floor said the old floor did not need a coating)2. Was this vinyl tile installed correctly?3. If it wasn‘t installed correctly, could this affect the vinyl tile/planks over time -- could it warp, perhaps? 4. What do I do if it was installed incorrectly and the company does not do anything about it without a fee?? (There‘s a warantee on the floor IF it was installed correctly only)

- The new vinyl floor should only have been applied to a good, sound and stable substrate. If the tiles underneath were chipping, flaking, bubbling or falling apart there is no way the new flooring should have been applied. Most asbestos tile comes up easily and requires basic Personal Protective Equipment. Not like asbestos pipe installation...the nasty stuff. Another option is to remove the loose tile and fill with a latex floor patch...not the best option, but OK for most. A better option is a 1/4 plywood underlayment on top of the tile and under the new vinyl. You still need to remove lose or bad tile and level uneven areas, but the new plywood underlayment will give you a much more stable surface. You'll need to prime the plywood with a floor primer and also consider a new threshold to account for the elevation difference.

- Q: What are the pros and cons for using porcelain tiles or ceramic tiles?

- From a design perspective, it depends on the application. Porcelain tiles have the color permeated throughout the tile. That means, for example, if you use them say around a bathtub deck as a back splash the side of the tile that is exposed will have the same design on the front. With ceramic tile, it will have the color of the clay which means you have to use a finish tile or edge tile to conceal that because it does not look nice. Because the pattern goes all of the way through a porcelain tile, some people feel it gives a more realistic replica of certain stones than ceramic does. And, there are claims that porcelain tiles are more durable than ceramic.

- Q: Classification of ceramic tiles

- 4, antique brick: not China's ceramic industry's products, is introduced from abroad. Antique tiles are evolved from glazed tiles, essentially glazed porcelain tiles. Compared with ordinary glazed tiles, the difference is mainly reflected in the color of the glaze above, antique tiles are ordinary tiles, and the disk is basically the same, the so-called antique, refers to the effect of brick, antique effect should be called tiles, Antique brick is not easy to clean. The only difference is in the firing process, the antique brick technical requirements are relatively high, thousands of tons of hydraulic press after pressing, and then by thousands of high temperature sintering, to its high strength, with a strong wear resistance, carefully developed Antique tiles both waterproof, non-slip, corrosion-resistant features. Antique brick imitation of the past style to do the old, with a unique charm with classical people to attract people's eyes, to reflect the vicissitudes of life, the history of heavy, antique brick through the style, color, pattern, to create a nostalgic atmosphere. 5, ceramic tiles: also known as mosaic, specifications, thin and small, hard texture, acid, alkali, wear, no water, strong pressure, not broken, colorful and versatile. 6, quintana brick: This is a glazed porcelain tiles, a very good anti-skid and wear resistance. Generally speaking, "anti-skid tiles" are mostly quintana bricks. As this kind of brick price is moderate, popular consumer favorite.

Send your message to us

Glazed Floor Tile 300*300mm Item No. CMAX3A435

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1683 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches