Fiberglass Mat Tissue Glass Blanket Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

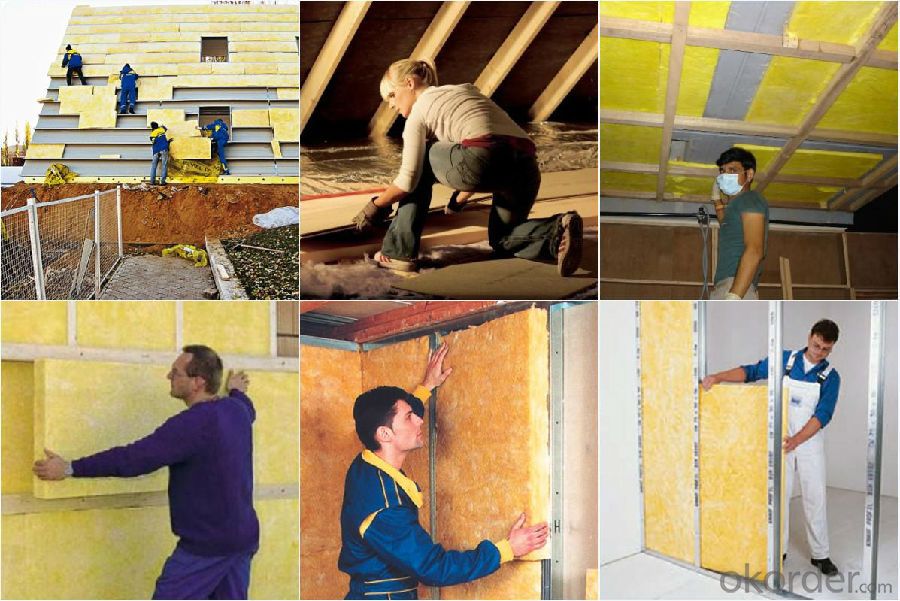

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can fiberglass mat tissue be used for windbreak panels?

- Yes, fiberglass mat tissue can be used for windbreak panels. It is a lightweight and durable material that can provide effective protection against wind and other environmental elements.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. It is a commonly used material in the manufacturing of nacelles due to its lightweight, high strength, and excellent weather resistance properties.

- Q: How does the roll weight of fiberglass mat tissue affect its transportation?

- The roll weight of fiberglass mat tissue directly affects its transportation in terms of the ease and cost. Heavier rolls will require more effort and resources for handling, loading, and unloading. They may also require specialized equipment for transportation, leading to higher shipping costs. On the other hand, lighter rolls are easier to handle and transport, reducing the overall logistical challenges and expenses.

- Q: Can fiberglass mat tissue be used for wind turbine blades?

- Indeed, wind turbine blades can utilize fiberglass mat tissue. This material, known for its lightness and durability, finds widespread use in constructing wind turbine blades. It boasts an impressive strength-to-weight ratio and possesses resistance against corrosion, making it an optimal choice for enduring the harsh environmental circumstances faced by wind turbine blades. Moreover, fiberglass mat tissue can effortlessly be shaped into intricate forms, enabling the production of aerodynamically efficient wind turbine blades. All in all, integrating fiberglass mat tissue into wind turbine blades enhances their performance and longevity.

- Q: What are the potential environmental impacts of using fiberglass mat tissue?

- The potential environmental impacts of using fiberglass mat tissue include the release of harmful airborne particles during production and installation, which can contribute to air pollution and respiratory issues. Additionally, the disposal of fiberglass mat tissue can pose challenges as it is not biodegradable and may contribute to landfill waste.

- Q: How does the fiber orientation of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is heavily influenced by the orientation of its fibers. Fiberglass mat tissue is a composite material consisting of glass fibers that are randomly distributed and held together by a binder material. When the fibers are randomly oriented, the material exhibits isotropic strength properties. This means that it has similar mechanical properties, such as tensile strength and stiffness, in all directions. Random fiber orientation provides an even distribution of load-bearing capability throughout the material, making it resistant to both tensile and compressive forces from any direction. Alternatively, when the fibers are oriented in a specific direction, the material becomes anisotropic. This means that it has directional strength properties. In this case, the material is stronger and stiffer along the direction of the fibers, while its strength decreases in other directions perpendicular to the fiber orientation. This anisotropic behavior is due to the fact that the fibers primarily bear the load, while the binder material provides support and cohesion between the fibers. By manipulating the fiber orientation during manufacturing, it is possible to customize the strength and performance characteristics of fiberglass mat tissue for specific applications. For example, in the construction industry, where strength is required in a particular direction for reinforcing concrete, or in the aerospace industry, where structural components need maximum strength along a specific load path, the fibers can be aligned accordingly. In conclusion, the fiber orientation of fiberglass mat tissue directly impacts its strength. Random fiber orientation results in isotropic strength properties, providing balanced strength in all directions. Alternatively, specific fiber alignment creates anisotropic strength properties, allowing for enhanced strength along the direction of the fibers. This ability to control fiber orientation enables the customization of fiberglass mat tissue to meet the specific strength requirements of different industries and applications.

- Q: Is fiberglass mat tissue suitable for HVAC insulation?

- Fiberglass mat tissue is indeed a suitable material for HVAC insulation. It is a lightweight and flexible substance commonly utilized in insulation applications due to its exceptional thermal insulation properties. With its effective heat insulation, it assists in maintaining a comfortable and energy-efficient environment within HVAC systems. Moreover, fiberglass mat tissue's resistance to moisture prevents the growth of mold or mildew, making it an appropriate choice for HVAC insulation in areas where condensation and moisture may occur. Its easy installation and ability to be cut to fit around HVAC components ensure a proper and secure insulation seal. In summary, fiberglass mat tissue is a dependable and long-lasting insulation material extensively employed in HVAC systems to enhance energy efficiency and thermal performance.

- Q: Can fiberglass mat tissue be used for insulating metal roofs?

- Indeed, insulating metal roofs is possible with the utilization of fiberglass mat tissue. The thermal properties and durability of fiberglass make it a favored selection for roof insulation. By obstructing heat transfer, it aids in maintaining a cooler interior during scorching weather and a warmer one during chilly weather. Moreover, fiberglass is lightweight and straightforward to install, rendering it a pragmatic choice for metal roofs. Generally, the fiberglass mat tissue is positioned between the metal roof panels and the building's interior, furnishing an efficient insulation layer.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Yes, fiberglass mat tissue can be used for insulation in cleanrooms. It is a commonly used material due to its excellent thermal insulation properties, low cost, and high resistance to chemicals and moisture. Additionally, fiberglass mat tissue has low particulate emission, making it suitable for cleanroom environments where maintaining a controlled and sterile atmosphere is crucial.

- Q: Is fiberglass mat tissue suitable for railway rolling stock?

- Indeed, fiberglass mat tissue proves to be a fitting option for railway rolling stock. This lightweight and resilient material is frequently utilized in the construction sector for a multitude of purposes, including the production of railway rolling stock. Its exceptional mechanical robustness and resistance to corrosion render it optimal for deployment in the challenging and rigorous settings characteristic of railway rolling stock operations. Furthermore, fiberglass mat tissue exhibits commendable thermal insulation characteristics, contributing to enhanced energy efficiency within the rolling stock. All in all, fiberglass mat tissue emerges as a suitable and dependable selection for the construction and upkeep of railway rolling stock.

Send your message to us

Fiberglass Mat Tissue Glass Blanket Glass Wool Building Materials with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords