Fiberglass Mat Tissue Glass Wool Home Insulation Product with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

g):ventilation property

Glass wool, with multiaperture structure and special prescription, make its better performance in ventilation property. It contribute to moisture diffusion indoor and wall and greatly decrease the possibility of leaf mold growth. Thus it can help to increase service life of building and indoor comfort level.

h): Hydrophobicity

Hydrophobicity glass wool in panel wall bears 99% Hydrophobicity rate. It can easily get dry naturally, which ensure its long-term heat preservation perporty.

i): Light in weight

Glass wool bears good heat preservation and soundproofing property. It’s low density product can meet energy saving requirement. Thus it helps to decrease the weight of building and makes the construction more expedite.

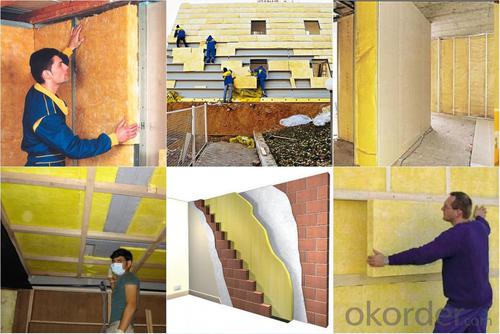

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the impact resistance of fiberglass mat tissue at high temperatures?

- The impact resistance of fiberglass mat tissue at high temperatures is generally quite good. The fiberglass material offers excellent strength and durability, allowing it to maintain its structural integrity even when exposed to elevated temperatures. However, it is important to note that the specific impact resistance can vary depending on factors such as the thickness and composition of the fiberglass mat tissue. Overall, fiberglass mat tissue is known for its ability to withstand impacts and maintain its performance even under high temperature conditions.

- Q: Can fiberglass mat tissue be used for creating molds?

- Using fiberglass mat tissue for creating molds is not possible. Fiberglass mat tissue is primarily utilized as a reinforcement layer in fiberglass composite applications due to its thin and lightweight nature. It is not intended to be used as a material for making molds. Instead, molds are commonly made using silicone, resin, or plaster, as these materials have the capacity to capture intricate details and offer a polished surface finish.

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue has low air permeability, meaning it restricts the flow of air.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- Generally, fiberglass mat tissue is not utilized for HVAC insulation. The insulation used in HVAC systems typically necessitates materials that are purposely engineered to possess significant thermal resistance and inhibit the transmission of heat or cold air. Fiberglass mat tissue is frequently employed as a reinforcing material in the construction of composite materials, such as fiberglass panels or structures, rather than for insulation purposes. Insulation materials intended for HVAC systems are commonly composed of materials such as fiberglass insulation boards, foam insulation, or mineral wool, which possess superior thermal resistance properties and are specifically tailored for HVAC applications.

- Q: Is fiberglass mat tissue resistant to mold growth?

- Yes, fiberglass mat tissue is resistant to mold growth.

- Q: Is fiberglass mat tissue resistant to termites and insects?

- Yes, fiberglass mat tissue is generally resistant to termites and insects. Fiberglass is made from woven glass fibers, which are not a food source for termites or insects. Additionally, fiberglass mat tissue is typically coated with a layer of resin, which further enhances its resistance to pests. This makes fiberglass mat tissue a popular choice for construction and insulation applications in areas prone to termite and insect infestations. However, it is worth noting that while fiberglass mat tissue itself is resistant to termites and insects, it does not guarantee complete protection against infestations. It is always advisable to take additional measures, such as proper sealing and regular inspections, to ensure long-term pest control.

- Q: How does fiberglass mat tissue perform in terms of moisture resistance?

- Renowned for its exceptional resistance to moisture, fiberglass mat tissue is composed of tightly woven strands of fiberglass that form a formidable barrier against the infiltration of water. This remarkable feature renders it highly efficient in thwarting the permeation of water or moisture, thus safeguarding the integrity of underlying surfaces and structures. Furthermore, the incorporation of resin as a binding agent among the fiberglass strands offers an additional safeguard against moisture, augmenting its ability to withstand water and humidity. Consequently, fiberglass mat tissue emerges as a dependable option for moisture resistance, rendering it ideal for a wide range of applications where the prevention of water damage is of utmost importance.

- Q: How does fiberglass mat tissue compare to polyurethane insulation?

- Fiberglass mat tissue and polyurethane insulation have different characteristics and purposes. Fiberglass mat tissue is commonly used as a reinforcing material in composite structures, providing strength and stability. On the other hand, polyurethane insulation is specifically designed to reduce heat transfer and improve energy efficiency in buildings. Therefore, while fiberglass mat tissue enhances structural integrity, polyurethane insulation primarily focuses on thermal insulation properties.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue is determined by several factors, including the mat's thickness, fiber density, and the inclusion of additional materials or coatings. In general, fiberglass exhibits low thermal resistance, signifying its excellent heat conductivity. Nevertheless, when employed as insulation, the thickness and density of the fiberglass mat can elevate its thermal resistance, enhancing its ability to reduce heat transfer. It is crucial to acknowledge that precise thermal resistance values may differ based on the product and application, hence it is advisable to consult the manufacturer's specifications for precise information.

- Q: What are the typical roll sizes available for fiberglass mat tissue?

- The typical roll sizes available for fiberglass mat tissue vary depending on the manufacturer and the specific application. However, in general, fiberglass mat tissue is available in roll sizes ranging from 50 inches to 120 inches in width and 100 yards to 1,000 yards in length. These sizes are commonly used in industries such as construction, automotive, and marine for various purposes like insulation, reinforcement, and soundproofing. It is important to note that the availability of specific roll sizes may differ based on the supplier and the intended use of the fiberglass mat tissue.

Send your message to us

Fiberglass Mat Tissue Glass Wool Home Insulation Product with CE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords