GJM 25 Insulating Fire Brick - Mullite Insulation Brick Product

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

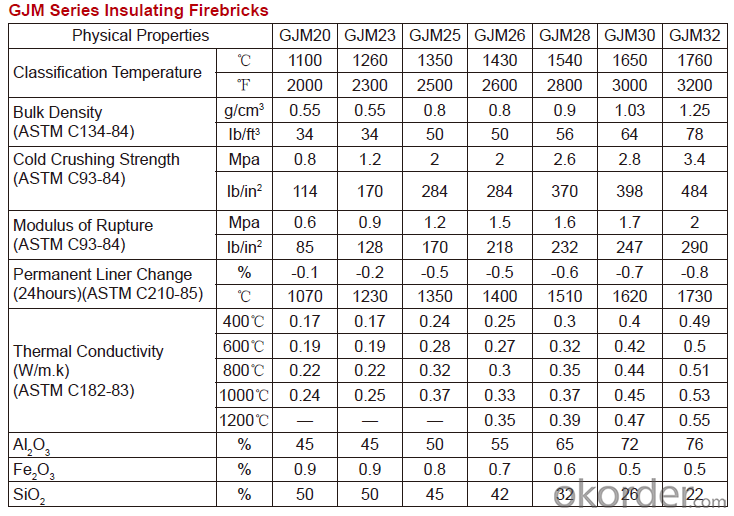

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in sewage treatment plants?

- Yes, insulating fire bricks can be used in sewage treatment plants. Insulating fire bricks are designed to have excellent thermal insulation properties, which make them suitable for high-temperature applications. In sewage treatment plants, there are often processes that involve the use of heat, such as anaerobic digestion or sludge incineration. Insulating fire bricks can be used to line the walls, floors, and roofs of the incinerators or digesters, helping to retain the heat generated and improve energy efficiency. Additionally, sewage treatment plants often deal with corrosive and abrasive environments due to the presence of chemicals, acids, and solids in the wastewater. Insulating fire bricks are made from high-quality refractory materials that are resistant to chemical attack and erosion. This makes them a suitable choice for lining tanks, pipes, or other equipment that may come into contact with corrosive substances. Furthermore, insulating fire bricks are lightweight, which makes them easier to handle and install compared to other types of refractory materials. This can be beneficial in sewage treatment plants where there might be a need for frequent maintenance or repairs. Overall, insulating fire bricks are a versatile and durable option for use in sewage treatment plants, providing excellent thermal insulation, resistance to corrosive environments, and ease of installation.

- Q: Do insulating fire bricks have good insulation performance at high temperatures?

- Yes, insulating fire bricks have excellent insulation performance at high temperatures. These bricks are designed specifically to withstand extremely high temperatures and provide a high level of thermal insulation. They are made from lightweight materials that have low thermal conductivity, allowing them to effectively trap and contain heat within a furnace, kiln, or other high-temperature applications. This insulation property helps in reducing heat loss and maintaining a consistent temperature inside the structure. Insulating fire bricks are widely used in industries such as ceramics, metallurgy, glass-making, and heat treatment, where maintaining high temperatures and thermal efficiency are crucial.

- Q: Can insulating fire bricks be used in the construction of pottery molds?

- Insulating fire bricks are indeed applicable for the construction of pottery molds. Crafted from lightweight refractory materials, these bricks possess exceptional heat insulation qualities. Specifically engineered for high-temperature applications like pottery kilns, they offer a range of benefits. When constructing pottery molds, it is imperative to utilize materials that can endure the kiln's intense heat. Insulating fire bricks can withstand temperatures of up to 3000°F (1650°C), rendering them ideal for pottery mold construction. They provide insulation to prevent heat dissipation and maintain consistent temperatures within the kiln, crucial for achieving the desired firing results. Moreover, insulating fire bricks can be conveniently shaped and cut to suit the designated mold design. Their lightweight nature also simplifies handling during the mold construction process. Additionally, the insulating properties of these bricks curtail energy consumption by preventing excessive heat loss, making them a cost-effective choice in the long term. All in all, insulating fire bricks prove to be a fitting option for constructing pottery molds due to their capacity to withstand high temperatures, offer insulation, and be easily molded to meet specific design requirements.

- Q: Are insulating fire bricks resistant to fire damage?

- Yes, insulating fire bricks are specifically designed to be resistant to fire damage. They are made from special refractory materials that can withstand extremely high temperatures without deforming or losing their insulating properties. Insulating fire bricks have a high melting point and low thermal conductivity, which allows them to effectively insulate against heat transfer and protect against fire damage. They are commonly used in applications where high temperatures and fire exposure are expected, such as in furnaces, kilns, fireplaces, and industrial processes. Overall, insulating fire bricks are reliable and durable materials that provide excellent protection against fire damage.

- Q: Do insulating fire bricks have a high resistance to spalling?

- Yes, insulating fire bricks have a high resistance to spalling. Spalling refers to the breaking off or flaking of the surface of a material, and in the case of fire bricks, it typically occurs due to high temperatures and thermal shock. Insulating fire bricks are specifically designed to withstand these extreme temperatures and thermal cycling, making them highly resistant to spalling. These bricks are made from high-quality refractory materials, such as alumina or silica, which have excellent thermal shock resistance. Additionally, they are manufactured with a low thermal conductivity, which helps to minimize heat transfer and reduce the risk of spalling. Overall, insulating fire bricks are an ideal choice for applications where high resistance to spalling is required, such as in furnaces, kilns, and other high-temperature environments.

- Q: Can insulating fire bricks be used in high-temperature insulation blankets for aerospace applications?

- Insulating fire bricks are not typically used in high-temperature insulation blankets for aerospace applications due to their solid and rigid nature, which makes them unsuitable for flexible and conformable insulation. Instead, aerospace insulation blankets are typically made from flexible and lightweight materials like ceramic fiber or silica fiber. These materials offer excellent thermal insulation properties and can easily mold and shape to fit complex geometries. They provide effective heat insulation and protection for critical components. Additionally, insulation blankets in aerospace applications must meet stringent requirements such as low outgassing, high thermal stability, and resistance to vibration and mechanical stress. Insulating fire bricks may not satisfy these specific requirements and may not withstand the extreme conditions in aerospace environments. In conclusion, while insulating fire bricks excel in certain high-temperature insulation applications, they are not appropriate for aerospace insulation blankets. The aerospace industry demands insulation materials that are flexible, lightweight, and high-performing, capable of conforming to intricate shapes and enduring the unique challenges of this sector.

- Q: Can insulating fire bricks be used in biomass power plants?

- Insulating fire bricks possess the capability to be utilized within biomass power plants. Specifically designed to endure extreme temperatures and offer insulation, these fire bricks are well-suited for an array of applications in high-temperature settings, including biomass power plants. These power plants generate electricity by incinerating biomass materials such as wood chips, agricultural waste, and other organic substances. The usage of insulating fire bricks can span across multiple areas within a biomass power plant. Primarily, they can be employed to line the combustion chamber where the biomass is burned, releasing heat. The insulating properties of these bricks aid in containing the heat within the combustion chamber, thereby enhancing the efficiency of the biomass combustion process. Furthermore, insulating fire bricks serve a purpose in the construction of the plant's boiler, responsible for converting the heat produced by the biomass incineration into steam. The bricks can be utilized to line the walls and roof of the boiler, delivering thermal insulation and preventing heat loss. This insulation serves to maintain high temperatures inside the boiler, which is vital for steam generation and subsequent power production. Moreover, the construction of the chimney or flue system of biomass power plants can also incorporate insulating fire bricks. These bricks can be utilized to line the interior of the chimney, ensuring that the high temperatures and corrosive gases resulting from biomass combustion are safely contained and directed out of the plant. In summary, insulating fire bricks are an exceptional choice for biomass power plants due to their ability to withstand high temperatures and provide thermal insulation. Their utilization in the combustion chamber, boiler, and chimney systems contributes to the improvement of efficiency and safety in biomass power generation.

- Q: Are insulating fire bricks resistant to molten metals?

- Insulating fire bricks, in general, exhibit resistance to molten metals. These bricks are composed of refractory materials with high melting points and exceptional thermal insulation properties, rendering them appropriate for high-temperature scenarios involving molten metals. The insulation capabilities of these bricks serve to curtail heat transfer, thereby preventing the conduction of heat from the molten metal through the brick. Furthermore, the refractory materials employed in these bricks possess minimal thermal expansion, enabling them to endure the thermal shock that may arise upon contact with molten metals. However, it is important to acknowledge that the resistance of insulating fire bricks to molten metals may vary based on factors such as metal type, temperature, and duration of exposure. Hence, it is advisable to consult the manufacturer or a professional to ascertain the suitability of insulating fire bricks for the specific application involving molten metals.

- Q: Are insulating fire bricks resistant to freeze-thaw cycles?

- Yes, insulating fire bricks are generally resistant to freeze-thaw cycles. These bricks are designed to have low thermal conductivity and high resistance to thermal shock, which makes them highly durable and capable of withstanding extreme temperature variations, including freeze-thaw cycles. This resistance to freeze-thaw cycles is crucial in applications where the bricks are exposed to fluctuating temperatures, such as in furnaces, kilns, and other high-temperature environments. The insulating properties of these bricks also help to minimize heat loss and prevent moisture penetration, further enhancing their resistance to freeze-thaw cycles. However, it is important to note that the specific composition and manufacturing process of the insulating fire bricks can vary, so it is always recommended to consult the manufacturer's specifications and guidelines to ensure the bricks are suitable for the intended application.

- Q: Can insulating fire bricks be used for chimney lining?

- Yes, insulating fire bricks can be used for chimney lining. Insulating fire bricks are designed to withstand high temperatures and are excellent for insulating chimneys, providing thermal protection and enhancing energy efficiency.

Send your message to us

GJM 25 Insulating Fire Brick - Mullite Insulation Brick Product

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords