Galvanized Steel Strips with Width 610mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Hot-Dip Galvanized Steel Strips Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2. Main Features of the Hot-Dip Galvanized Steel Strips:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

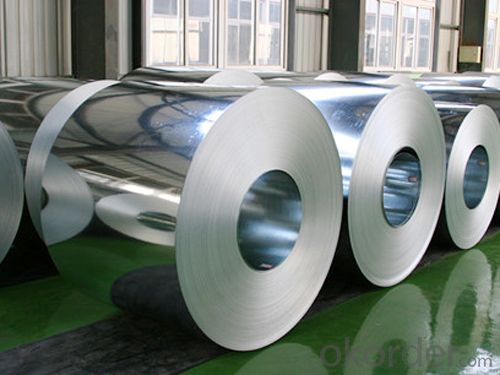

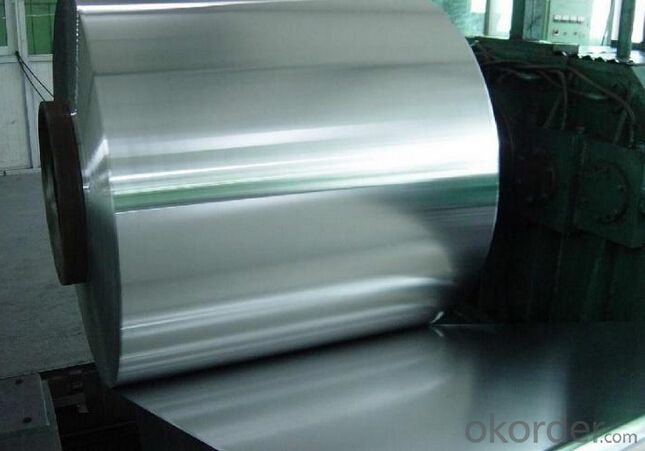

3. Hot-Dip Galvanized Steel Strips Images

4. Hot-Dip Galvanized Steel Strips Specification

1) Capacity: about 15,000 tons per month for sheet product.

2) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request

3) Thickness: 0.13mm-0.5mm

4) Width: 400mm-1000mm

5) Length: We can adjust the length according to your request

6) Zinc Coating Weight: 60g/m2-275g/m2

7) Raw Materials: Galvanized steel sheet and Pre-painted galvanized steel sheet

8) Spangle: Regular spangle, minimized spangle and zero spangle

9) Hardness: Full hard, normal

Thickness | Width | Length | ZincCoating Weight | Color Series |

0.13mm-1.0mm | 400mm-1000mm | As your request | 60g/m2-275g/m2 | RAL,or other series |

5.FAQ of Hot-Dip Galvanized Steel Strips

We have organized several common questions for our clients,may help you sincerely:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Production period is 30 days. And we’d prefer you can give us more time to book vessel.

3. What’s the usage of cold rolled steel coil?

Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and standards set by the industry or customer. Generally, it ranges from 10 to 20 micro-inches (0.25 to 0.5 micrometers), but it is important to consult the relevant specifications for the specific application.

- Q: How are steel coils processed for painting or coating?

- Steel coils are processed for painting or coating through a series of steps. First, the coils are cleaned and treated to remove any impurities, such as oil, dirt, or rust, using chemical treatments or mechanical methods like abrasive blasting. Then, a primer or base coat is applied to enhance adhesion and provide corrosion resistance. After drying, the topcoat or finishing coat is applied using various techniques like coil coating, electrostatic spraying, or powder coating. Finally, the coated steel coils undergo curing or baking at high temperatures to ensure proper adhesion and durability of the paint or coating.

- Q: What are the dimensions of steel coils used in the power generation industry?

- The dimensions of steel coils used in the power generation industry vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry are typically in the range of 0.5 to 3.0 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coil can vary, but it is often in the range of several hundred to several thousand meters.

- Q: How are steel coils used in the production of automotive engine components?

- Steel coils are used in the production of automotive engine components by being processed and shaped into various parts, such as pistons, crankshafts, and connecting rods. The coils are first cut, stamped, and formed into the desired shapes, and then undergo heat treatment and other machining processes to enhance their strength and durability. These components are crucial for the proper functioning of an automotive engine, as they provide structural support and help convert the energy generated by the combustion process into mechanical motion.

- Q: I have to explain some functions of stainless steel but after days of searching I cant find an answer. Thankyou in advance for your help :)

- IT doesn't rust.

- Q: They say it's some six times stronger than steel. need some explanation.

- Most importantly, spider silk is extremely lightweight: a strand of spider silk long enough to circle the Earth would weigh less than 500 grams (18 oz). Spider silk is also especially ductile, able to stretch up to 140% of its length without breaking. It can hold its strength below ?40 °C. This gives it a very high toughness (or work to fracture), which equals that of commercial polyaramid (aromatic nylon) filaments, which themselves are benchmarks of modern polymer fiber technology. What this means in regard to what you have heard is that if you compared the tensile strength (type 'tensile strength' on wikipedia if you do not know what it means) of spider silk and a strand of steel at the same thickness, the silk would have a higher tensile strength than many grades of steel, upto that of high grade steel - of which they are about the same.

- Q: What are the common uses of coated steel coils?

- Common uses of coated steel coils include roofing, siding, automotive parts, appliances, and building materials. The coating on the steel helps to protect it from corrosion and enhances its durability, making it suitable for various applications in industries such as construction, manufacturing, and transportation.

- Q: How are steel coils measured for thickness?

- Steel coils are measured for thickness using a device called a micrometer or a thickness gauge. The micrometer is pressed against the coil's surface, and the measurement is displayed on its calibrated scale, providing an accurate reading of the steel coil's thickness.

- Q: I've heard different things bout them, though I do not know this. Oh, and if you know where you can buy some raw or get custom made stuff out of black steel please let me know it would be greatly appreciated. Oh and my friend told me there is a black steel that can be sharpened and silver will be underneath, is this also true? Thank you very much for answering ^^

- black steel and black tron are not same.

- Q: How are steel coils used in the manufacturing of metal structures?

- Steel coils are used in the manufacturing of metal structures as they are shaped and formed into various components such as beams, columns, and plates. These coils are unrolled and processed through machines that cut, shape, and weld them together to create the desired structure. The strength and durability of steel make it an ideal material for constructing buildings, bridges, and other metal structures.

Send your message to us

Galvanized Steel Strips with Width 610mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords