Hot Rolled Stainless Steel Coil 304 Wide Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

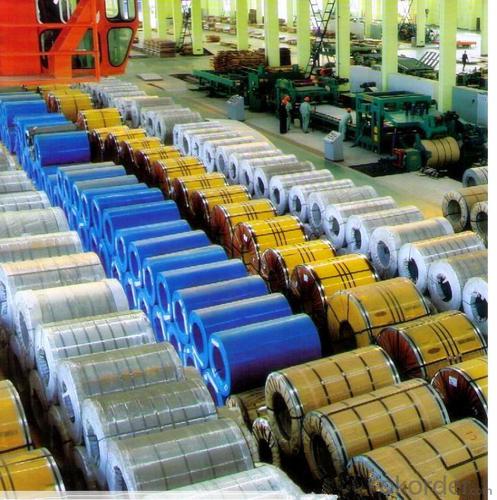

Hot Rolled Stainless Steel Coil 304 Wide Strip

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.my company long-term

supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 1.0m, 1.22m, 1.5m, 2.0m or requirement

ASTM 304

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 |

Thickness | 3.0mm-4.0mm |

Width | 1000mm, 1219mm, 1240mm, 1500mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 5000 tons/month |

- Q: Are 111 stainless steel strips suitable for chemical storage tanks?

- No, 111 stainless steel strips may not be suitable for chemical storage tanks as they are not resistant to certain corrosive chemicals.

- Q: How do stainless steel strips resist embrittlement in high-temperature applications?

- Stainless steel strips are known for their exceptional resistance to embrittlement in high-temperature applications. This resistance is primarily attributed to the unique composition and microstructure of stainless steel. Stainless steel is an alloy that contains a significant amount of chromium, typically ranging from 10-30%. The presence of chromium in stainless steel plays a crucial role in its resistance to embrittlement. Chromium forms a passive oxide layer on the surface of stainless steel, known as chromium oxide or Cr2O3. This oxide layer acts as a protective barrier, preventing the diffusion of harmful elements and reducing the susceptibility to embrittlement. In high-temperature environments, stainless steel strips retain their resistance to embrittlement due to the stability of the chromium oxide layer. This layer remains intact even at elevated temperatures, providing a continuous barrier against the corrosive and embrittling effects of the surrounding environment. Furthermore, stainless steel also contains other alloying elements such as nickel and molybdenum, which contribute to its high-temperature strength and resistance to embrittlement. These elements enhance the stability of the microstructure, preventing the formation of brittle phases and maintaining the ductility of the stainless steel strips. The fine-grained microstructure of stainless steel is another key factor in its resistance to embrittlement. The fine grains inhibit the propagation of cracks and reduce the overall susceptibility to fracture, even at high temperatures. Additionally, the presence of carbides, nitrides, or other precipitates within the stainless steel matrix can help to pin dislocations and prevent their movement, further enhancing the resistance to embrittlement. Overall, stainless steel strips resist embrittlement in high-temperature applications due to the protective chromium oxide layer, the presence of alloying elements, the stability of the microstructure, and the inhibiting effects of precipitates. These factors combine to ensure that stainless steel maintains its strength, ductility, and resistance to fracture, even under extreme temperature conditions.

- Q: What are the maximum operating temperatures for stainless steel strips?

- The maximum operating temperatures for stainless steel strips differ based on the grade of stainless steel in use. In most cases, stainless steel strips can handle temperatures ranging from 1500°F to 1600°F (815°C to 870°C). It is crucial to consider that temperature limits can vary due to factors like alloy composition, surface finish, and intended application. Thus, it is advisable to refer to the manufacturer's specifications or seek expert advice to ascertain the precise maximum operating temperature for a particular grade of stainless steel strips.

- Q: Can stainless steel strips be used in the production of aerospace fasteners?

- Yes, stainless steel strips can be used in the production of aerospace fasteners. Stainless steel is a commonly used material in the aerospace industry due to its excellent mechanical properties, corrosion resistance, and high strength-to-weight ratio. Stainless steel strips can be formed, cut, and shaped into various fastener components such as screws, bolts, nuts, and washers. These fasteners are crucial for joining and securing different parts of an aircraft or spacecraft. Additionally, stainless steel's resistance to high temperatures and extreme environments makes it a suitable choice for aerospace applications.

- Q: Can 111 stainless steel strips be coated or plated for added protection?

- Yes, 111 stainless steel strips can be coated or plated for added protection. Coating or plating the strips with a protective layer can enhance their resistance to corrosion, wear, and other forms of damage. The specific coating or plating material used will depend on the desired level of protection and the intended application of the strips. Common coating options for stainless steel include epoxy, acrylic, and powder coatings, while plating options may include nickel, chrome, or zinc. It is important to carefully consider the intended use and environment of the strips to select the most suitable coating or plating technique.

- Q: How do 111 stainless steel strips perform in acidic environments?

- The corrosion resistance and durability of stainless steel are well-known characteristics. However, when it comes to 111 stainless steel strips in acidic environments, their performance can vary depending on the alloy's specific composition and the acid concentration. Stainless steel grades with higher chromium content, like 111 stainless steel, typically exhibit excellent corrosion resistance in acidic environments. The presence of chromium in stainless steel results in the formation of a passive oxide layer on the material's surface. This oxide layer acts as a protective barrier against corrosion, preventing the acid from reaching the underlying metal and maintaining the stainless steel's integrity. Nevertheless, the performance of 111 stainless steel strips can be affected by the type and concentration of acid present. Even with higher chromium content, strong acids like hydrochloric acid or sulfuric acid can still pose a risk to stainless steel. The aggressive nature of these acids can cause localized corrosion or pitting on the stainless steel's surface. Therefore, it is crucial to consider the specific application and acid concentration when using 111 stainless steel strips in acidic environments. Depending on the circumstances, additional measures such as selecting a more corrosion-resistant stainless steel grade or applying protective coatings may be necessary to enhance the material's performance and longevity. To summarize, 111 stainless steel strips generally offer good corrosion resistance in acidic environments due to their higher chromium content. However, the type and concentration of acid present can influence their specific performance. Therefore, careful consideration of the application and potential risks is essential to ensure optimal performance and durability.

- Q: Are stainless steel strips suitable for architectural sculptures?

- Yes, stainless steel strips are often considered suitable for architectural sculptures due to their durability, versatility, and aesthetic appeal. They can be easily manipulated and formed into intricate designs, while their corrosion resistance ensures longevity in outdoor settings. The reflective surface of stainless steel strips also adds a modern and sleek touch to architectural sculptures.

- Q: How do you prevent galling of stainless steel strips?

- There are several measures that can be taken to prevent galling of stainless steel strips: 1. Lubrication is key in reducing the risk of galling. Applying lubricants like anti-seize compounds, oils, or greases creates a protective barrier between the surfaces, minimizing friction and the likelihood of galling. 2. Ensuring a smooth surface finish on the stainless steel strips helps prevent galling. Rough or uneven surfaces increase friction, making galling more likely. Polishing or grinding the surfaces creates a smoother finish, reducing the risk of galling. 3. Material selection plays a role in preventing galling. Some grades of stainless steel have better resistance to galling. For example, austenitic stainless steels with higher nickel content, such as 304 and 316, are known for their anti-galling properties. 4. Proper tightening is crucial. Applying the correct torque when fastening stainless steel strips together is important. Over-tightening can increase the risk of galling as excessive pressure can cause the surfaces to seize. Using a torque wrench or following manufacturer guidelines for tightening can prevent galling. 5. Avoiding metal-on-metal contact is another effective measure. Using non-metallic materials like plastic or rubber washers or inserts creates a barrier between the stainless steel strips, reducing friction and the likelihood of galling. In conclusion, a combination of lubrication, surface finish, material selection, proper tightening, and avoiding metal-on-metal contact effectively prevents galling of stainless steel strips.

- Q: What are the different types of stainless steel strip finishes?

- There exist various types of finishes for stainless steel strips, each possessing distinct characteristics and appearances. Some of the frequently encountered finishes are as follows: 1. No. 1 Finish: This is the most basic and widely utilized finish for stainless steel strips. By hot rolling the steel, a rough and dull surface texture is obtained. No. 1 finish is typically employed in industrial applications where appearance holds less significance. 2. No. 2D Finish: Referred to as a "dull" or "satin" finish, this type is achieved by cold rolling the stainless steel strip and subsequently annealing it in a controlled atmosphere. The outcome is a smooth, matte finish with low reflectivity. 3. No. 2B Finish: This finish shares similarities with No. 2D, yet exhibits a slightly brighter and smoother surface. It is accomplished by further cold rolling the strip and subjecting it to another round of annealing. No. 2B finish is commonly utilized in decorative applications and can be effortlessly cleaned. 4. No. 3 Finish: This finish showcases a semi-polished appearance, generated through mechanical polishing of the stainless steel strip. It is often employed in architectural and decorative applications where a polished, but not mirror-like, surface is desired. 5. No. 4 Finish: A favored finish for stainless steel strips employed in kitchen appliances and other decorative applications. It is accomplished by polishing the strip with abrasive belts or brushes, resulting in a brushed appearance featuring a consistent grain pattern. 6. No. 8 Finish: Also known as a "mirror" finish, this represents the shiniest and most reflective finish for stainless steel strips. By repetitively polishing the strip with progressively finer abrasives, a highly reflective surface is attained. No. 8 finish is frequently used in decorative and high-end applications.

- Q: What are the different types of edge finishes available for stainless steel strips?

- Stainless steel strips offer a variety of edge finishes, each with its own distinct look and purpose. The most commonly used edge finish is the mill edge. This finish is created during the hot rolling process, resulting in a straight, slightly rounded edge. It is a versatile choice and is often the default option for stainless steel strips. Another option is the slit edge finish, achieved by cutting the strip along its length to create two parallel edges. This finish is ideal for further processing or fabrication, as it provides a clean and consistent edge. For applications that prioritize safety and handling, the deburred edge finish is essential. This process involves removing any burrs or sharp edges from the strip, ensuring a smooth and safe surface. If frequent handling or contact with human skin is expected, the rounded edge finish is recommended. By rounding the edges of the strip, this finish offers a comfortable and safe edge. A beveled edge finish, on the other hand, is often used for decorative purposes or when joining multiple strips together. It provides an attractive transition between surfaces and helps minimize sharp edges. For applications where aesthetics take center stage, the polished edge finish is a popular choice. By buffing or polishing the edge, a smooth and shiny surface is achieved, enhancing the overall visual appeal. Alternatively, the brushed edge finish offers a unique appearance by brushing the edge with abrasive materials. This textured or matte surface can effectively hide imperfections or scratches. Ultimately, the selection of an edge finish depends on the specific requirements of the application, including aesthetics, functionality, and safety concerns. It is crucial to carefully evaluate the intended use and consult with experts to choose the most suitable edge finish for your stainless steel strip.

Send your message to us

Hot Rolled Stainless Steel Coil 304 Wide Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords