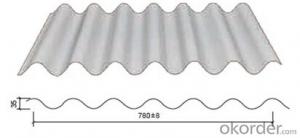

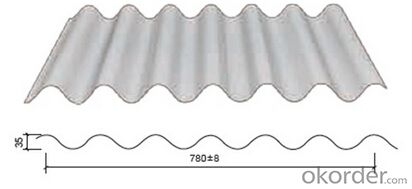

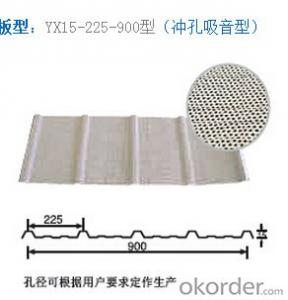

Galvanized Pressed steel plate 788

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colorful Galvanized Corrugated Pressed steel plate NO. 788

CNBM INERNATIONAL CORPORATION

1. A group corporation enjoying a competitive edge in the field of steel structure and new building boards, was founded in 1983 with the registered capital being 126 million yuan in exporting colored steel sheet, whose headquarters is located in Zhongguancun Fengtai Science Park, Beijing.

2. In the 1980s, CNBM has achieved professional advantages in the field of building metal profiled plates, and thenceforward it rapidly grew into an integrated enterprise group combining with design, manufacturing, construction, services and international trade. It is the main provider and market leader of steel structure and new construction boards in China. CNBM COLORED STEEL PLATE SANDWICH PANEL currently has 16 branches and 10 manufacturing plants respectively in Beijing, Tianjin, Hebei, Shenyang, Harbin, Baotou and Urumqi,

whose products have been exported to over 40 countries and regions around the world.

3 Today, CNBM is now the top 500 Fortun Globe has grown as an enterprise with such honors as Famous Trademark of China, the Best General Service Provider of Steel Structure Building System of China, the Leader of China's New Energy-efficient Construction Board Industry,

4. China’s Top ONE Construction Enterprises in the Steel Structure Industry, the High and New Technology Enterprises in Beijing, the High and New Technology Enterprises in Zhongguancun. DUOWEI is the main co-compiler of 16 national standards and industrial standards, and possesses the National Qualification of Class A in Architectural General Design, the Qualification of Grade A in Steel Structure Engineering Special Design, the Special-grade Qualification of Steel Structure Manufacturing, the Qualification of Class A in Professional Contracting for Steel Structure Projects and the certificate of ISO 9001: 2008 International Quality Management System Certification.

5. CNBM benefits its cooperative partners continuously, like the building owners and investors, with exquisite technologies, high-quality

products and differentiated services. DUOWEI steel structure products featured in high-rise steel structure, space steel structure, heavy frame steel structure and light steel structure, has reached to 250 thousand tons in annual production; the annual production capacity of CNBM polyurethane energy-saving sandwich boards, new fireproof rock wool/glass fiber cotton sandwich boards has reached to 3 million square meters;

6. The annual production capacity of CNBM adjustable steel truss floor support plates and closed composite slabs is 5 million square meters; and the annual production capacity of CNBM colorful profiled steel plates has reached to 30 million square meters.

7.CNBM Group has been making successes in serving PetroChina, Aerospace China,

China Nuclear Power, China FAW, China Guodian, China CNR, China Coal and other super large enterprises, and participating in national key projects, such as Hexie locomotive, National Grand Rocket, National Large Aircraft, Aerospace Coal Gasification, etc., and the group will continuously provide customers with innovative products and high-quality engineering services.

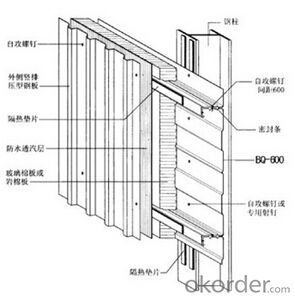

- Q: Can steel sheets be used for cladding?

- Yes, steel sheets can be used for cladding.

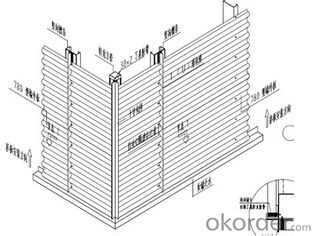

- Q: Can steel sheets be used for modular construction?

- Yes, steel sheets can be used for modular construction. Steel sheets are often used in modular construction due to their high strength, durability, and versatility. They can be easily fabricated into different shapes and sizes, making them suitable for constructing modular units such as walls, floors, and roofs. Additionally, steel sheets offer excellent resistance to fire, pests, and weather conditions, making them a popular choice in modular construction projects.

- Q: What are the safety considerations when working with steel sheets?

- When working with steel sheets, some safety considerations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toe boots to protect against cuts, burns, and falling objects. It is important to handle steel sheets with caution to avoid injury from sharp edges or corners. Additionally, ensuring proper ventilation in the work area is important to minimize exposure to potentially harmful fumes or dust particles. Regularly inspecting equipment and tools for any defects or damages is crucial to prevent accidents. Finally, following proper lifting techniques and using mechanical aids when necessary can help prevent strains or other musculoskeletal injuries.

- Q: Are the steel sheets heat-resistant?

- Yes, steel sheets are heat-resistant. Steel is known for its high melting point, which makes it a suitable material for applications that involve exposure to high temperatures. It can withstand heat without warping or losing its structural integrity. However, the exact level of heat resistance may vary depending on the specific type of steel and its composition. Some steel alloys are specifically designed to have even higher heat resistance, making them suitable for use in industries such as aerospace, automotive, and construction, where high-temperature environments are common.

- Q: Are steel sheets resistant to vibrations?

- Yes, steel sheets are generally resistant to vibrations due to their high strength and stiffness, which helps absorb and dampen vibrations effectively.

- Q: How do steel sheets compare to glass sheets?

- Steel sheets and glass sheets have distinct properties that make them suitable for different applications. Steel sheets are known for their strength, durability, and resistance to corrosion, making them ideal for construction, automotive, and industrial purposes. On the other hand, glass sheets are transparent, allowing light to pass through, making them well-suited for windows, mirrors, and decorative elements. While steel sheets provide security and structural integrity, glass sheets offer aesthetics and visual appeal. Ultimately, the choice between steel and glass sheets depends on the specific requirements and intended use of the material.

- Q: What are the standard dimensions of steel sheets?

- The standard dimensions of steel sheets vary depending on the specific application and industry requirements. However, common standard dimensions for steel sheets range from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 5 feet by 10 feet (1.5 meters by 3 meters).

- Q: Can steel sheets be used for electrical enclosures?

- Yes, steel sheets can be used for electrical enclosures. Steel is a commonly used material due to its durability, strength, and ability to provide electromagnetic shielding. It is suitable for protecting electrical components from external factors such as moisture, dust, and impact while also providing a safe and secure environment for the electrical equipment.

- Q: Can steel sheets be recycled after use?

- Yes, steel sheets can be recycled after use. Steel is a highly recyclable material, and recycling steel sheets helps to conserve energy and reduce the need for raw materials in steel production.

- Q: What is the tensile strength of a steel sheet?

- The tensile strength of a steel sheet generally ranges from 370 to 700 megapascals (MPa), depending on the specific type of steel and its thickness.

Send your message to us

Galvanized Pressed steel plate 788

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords