Corrugated Hot Dipped Galvanized Steel-Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Corrugated steel sheet is mostly used for architectural decoration. We have scores of corrugated sheets production lines of different types, producing profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings. Pressing steel panel can be freely incised, it can satisfy the especially designing demands. It apply on convenient construction, and anti-seismic performance, fire proof, waterproof, .

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Application:

It has been widely applied on civil construction like storerooms, special building roof and walls of wide-span steel structure building and so on.

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

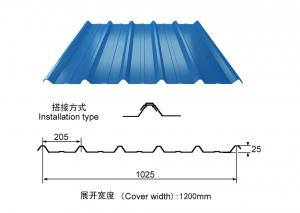

Product Specification:

Thickness tolerance: (+/-0.02mm)

Zinc coating: 40-180g/m2

Standard:jis g 3302, SGCH

Package: 2-3ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing

FAQ:

1. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

2.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

3. Could you produce the sheets according to our design?

Yes, we can make it.

- Q: Can steel sheets be used for magnetic applications?

- Indeed, magnetic applications can make use of steel sheets. However, it should be noted that not all steel types possess magnetic properties. Steel can be divided into two primary categories: ferromagnetic and non-ferromagnetic. Ferromagnetic steel comprises iron, nickel, and cobalt, which are materials capable of being magnetized. Conversely, non-ferromagnetic steel lacks these materials and is not magnetic. Ferromagnetic steel sheets find widespread application in magnetic uses such as transformers, motors, generators, and magnetic shielding. These sheets are preferred due to their ability to efficiently conduct and amplify magnetic fields. On the other hand, non-ferromagnetic steel sheets, while not magnetic themselves, can still be employed in magnetic applications as structural components or as part of a magnetic system where the magnetic field requires control or manipulation. When selecting steel sheets for magnetic applications, careful consideration must be given to the specific magnetic properties required for the intended use, and the appropriate type of steel should be chosen accordingly.

- Q: Are the steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications. Steel is a versatile and durable material that can withstand harsh weather conditions and provide long-term structural support. Steel sheets can be used in various agricultural applications such as constructing farm buildings, barns, sheds, and storage facilities. They can also be used for fencing, roofing, and siding purposes. Steel sheets offer excellent strength and resistance to pests, fire, and rot, making them ideal for protecting agricultural equipment and crops. Additionally, steel is recyclable, which makes it an environmentally-friendly choice for sustainable farming practices. Overall, steel sheets are a reliable and cost-effective solution for various agricultural applications.

- Q: How do steel sheets perform in terms of thermal conductivity?

- Steel sheets have a relatively high thermal conductivity, meaning they are able to transfer heat efficiently.

- Q: What are the different types of steel sheet finishes for industrial applications?

- There are several different types of steel sheet finishes commonly used in industrial applications. These finishes are applied to steel sheets to enhance their appearance, protect against corrosion, improve paint adhesion, and provide other functional benefits. Some of the most common types of steel sheet finishes include: 1. Hot Rolled: This finish is achieved by passing the steel through a high-temperature furnace, followed by rapid cooling. It results in a rough, scaled surface that is suitable for applications where appearance is not a primary concern. 2. Cold Rolled: In this finish, the steel is processed at room temperature, resulting in a smooth and clean surface. Cold-rolled steel sheets are often used in applications where a high-quality surface finish is required. 3. Galvanized: Galvanizing involves coating the steel sheet with a layer of zinc to protect against corrosion. This finish is widely used in industries such as construction, automotive, and manufacturing, where durability and resistance to rust are crucial. 4. Electro-galvanized: Similar to galvanizing, electro-galvanizing also involves coating the steel with zinc. However, in this process, an electric current is used to deposit the zinc onto the steel surface, resulting in a thinner and more controlled coating. 5. Stainless Steel: Stainless steel sheets are known for their high resistance to corrosion, making them ideal for applications in harsh environments. They can be finished with a variety of surface textures, including brushed, mirror, and patterned finishes. 6. Pickled and Oiled: This finish involves removing any oxide scale from the steel surface using an acid solution, followed by applying an oil coating to prevent rust formation. Pickled and oiled steel sheets are commonly used in automotive and construction industries. 7. Painted: Steel sheets can also be finished with a layer of paint, which not only enhances their appearance but also provides additional protection against corrosion. The type of paint used can vary depending on the application and desired finish. It's important to note that these are just a few examples of steel sheet finishes used in industrial applications. Different finishes are chosen based on the specific requirements of the application, such as aesthetics, corrosion resistance, durability, and cost-effectiveness.

- Q: Are steel sheets versatile in terms of design and customization?

- Yes, steel sheets are highly versatile in terms of design and customization. They can be cut, shaped, and formed into various sizes and shapes, making them suitable for a wide range of applications. Moreover, steel sheets can be painted, coated, or finished in different colors and textures, allowing for further customization to match specific design requirements.

- Q: Can steel sheets be painted or coated after installation?

- Yes, steel sheets can be painted or coated after installation. The paint or coating can provide added protection against corrosion and enhance the aesthetic appearance of the steel sheets.

- Q: Are steel sheets available in different colors?

- Yes, steel sheets are available in different colors. They can be coated or painted with various hues to meet specific aesthetic requirements.

- Q: What is the process of powder coating steel sheets?

- The process of powder coating steel sheets involves several steps. First, the steel sheets are cleaned and pre-treated to remove any dirt, grease, or rust. This is usually done through a combination of chemical cleaning and sandblasting. Next, the sheets are coated with a layer of electrostatically charged powder. The powder adheres to the steel sheets due to the opposite charges. After coating, the sheets are cured in an oven at high temperatures, typically around 400 degrees Fahrenheit. During this curing process, the powder melts and fuses onto the steel, creating a smooth and durable finish. Finally, the coated steel sheets are inspected for quality and packaged for shipping or further processing.

- Q: Can steel sheets be used for manufacturing shipping containers?

- Indeed, the utilization of steel sheets in the production of shipping containers is possible. Steel, being a robust and durable material, offers exceptional structural resilience, rendering it an ideal choice for the construction of shipping containers. Typically, steel sheets are employed in fabricating the container's walls, roof, and floor, guaranteeing its ability to endure the demanding conditions of transportation and safeguard the goods contained within. Moreover, steel exhibits resistance to diverse weather conditions, corrosion, and pests, thereby establishing it as a trustworthy option for the manufacturing of shipping containers.

- Q: Can steel sheets be used for food processing or storage?

- Yes, steel sheets can be used for food processing or storage. Steel is a durable and hygienic material that is commonly used in the food industry due to its resistance to corrosion, easy cleaning, and ability to maintain proper food safety standards.

Send your message to us

Corrugated Hot Dipped Galvanized Steel-Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords