Galvanized or Alu-zinc Steel PPGI/Color coated steel plate/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Galvanized or Alu-zinc Steel PPGI:

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

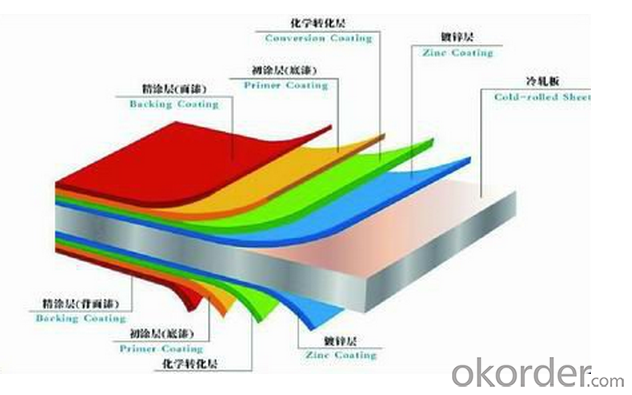

2.Features of Galvanized or Alu-zinc Steel PPGI:

With excellent cold-rolling steel strips as a base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Details of Galvanized or Alu-zinc Steel PPGI:

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Coil ID | 508mm&610mm |

Color | All RAL Color,or be customized |

Spangle | Regular/Zero/Big |

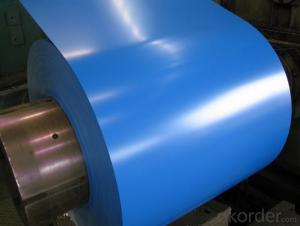

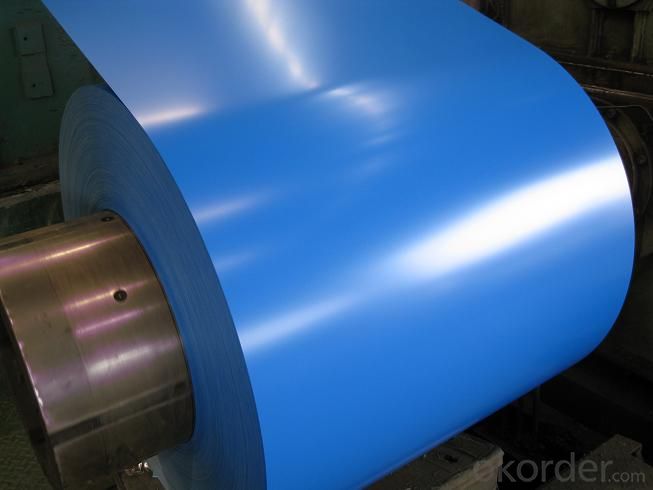

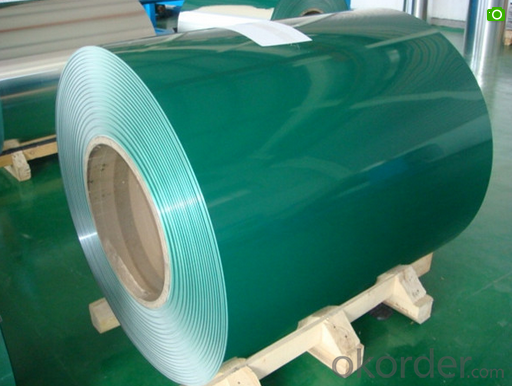

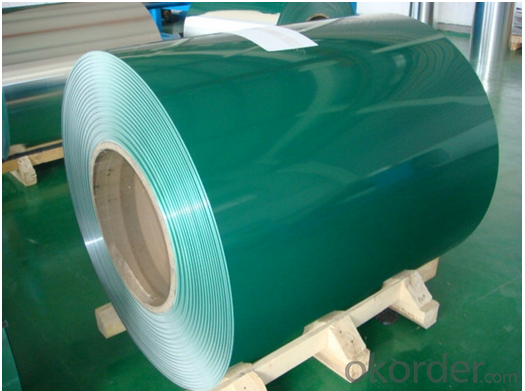

4.Galvanized or Alu-zinc Steel PPGI Image:

Packaging Details:Standard seaworthy packing

Delivery Detail: within 15-30 days

Packing &Delivery

Packing detail: 1. Metal Band Strapping

2. Outside Diameter Ring

3. Label 4. Protective Steel Sheet

5. Water and Rustproof paper 6. Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How is steel sustainable as a building material?How is wood sustainable as a building material?

- Wood as it comes from trees which are in nature.

- Q: How are steel coils inspected for dimensional accuracy after processing?

- Steel coils are inspected for dimensional accuracy after processing using various methods, such as manual measurement with precision tools, laser scanning technology, or automated vision systems. These inspection methods ensure that the dimensions of the steel coils meet the required specifications and tolerances, ensuring their quality and suitability for the intended applications.

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components by being processed and formed into various shapes such as beams, columns, and plates. These coils are first uncoiled and then cut into desired lengths before being shaped and welded together to create strong and durable structural components used in buildings, bridges, and other infrastructure projects.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide strength and durability to the ducts. These coils are shaped and formed into the desired ductwork design, providing a rigid structure that can withstand the pressure and movement of air. The steel coils also ensure that the ductwork maintains its shape over time, preventing any deformation or collapse.

- Q: I'm not really sure if carbon steel is considered a metallic material.

- Carbon and iron are both metallic.... so yes. You leave the iron laying in the forge - and it soaks up carbon atoms from the charcoal - so that as the steeling process goes on, the original iron becomes harder and harder.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed and shaped into the desired size and shape. The coils are first uncoiled and straightened, then cut into shorter lengths. These shorter lengths are then bent and twisted to create the necessary patterns and shapes, which provide enhanced strength and durability to the reinforcement bars.

- Q: every time i look for steel over the internet like to build cars motorcycles ect i only get steel pipes where can i get steel sheets

- This okorder /... Most towns have a steel supply house/ business, check your yellow pages. Also check with local welding and machine shops. They can give you ideas and or their suppliers. They often have bits and pieces that you might buy, instead of ordering a full sheet of material. Wingman

- Q: I just bought a dpms ar15 and it says if I shoot steel cases (laquer coated) or foreign ammo it voids the warranty. But before I knew this I bought 200 rounds of Russian steel cased anmo. Think I should just shoot there two hundred and not buy anymore? Some people say all they shoot is steel cased ammo and have no problemAny advice is appreciated

- I would probably buy a box of 20 brass cased ones and shoot them first to see that the gun works if you really believe that steel cased/foreign ammo voids the warranty. That way you will know that the rifle is functional from the factory. My son has a Rem 700 SPS Varmint that has only fired handloads and there are a couple of other rifles that have never had a factory round in them and the manufacturers claim that hand loads void warranties too.

- Q: how do i quinch steel? i heard instead of water oil will actually make it harder... wat ways are best for wat steels? and how do i tell wat kind of steel i have?... i will be doin this with my poket knife..

- boy what a though question ! let me explain. when you rapidly cool a steel from high temperatures(depending on steel type) with water or oil or other means , it is called quenching. it depends on the steel type to say if it is better to quench it with oil or water but basically in water you will have a harder steel rather than oil. for some steels if you do this you will ruin it's properties ! you can't totally tell what kind of steel do you have until you get it analyzed with Quantometer analyzer with a pocket knife it is more like an estimation and it can't be trust able generally if you can scratch the steel with your knife it means it is not a hard steel and it might not be expensive. I hope that helps but for more information i need to know more !

Send your message to us

Galvanized or Alu-zinc Steel PPGI/Color coated steel plate/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords