Galvanized Metal Studs And Tracks,Gypsum Drywall Metal Stud,Metal Studs Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

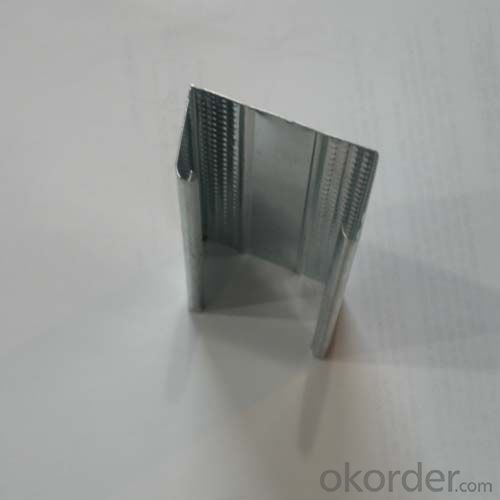

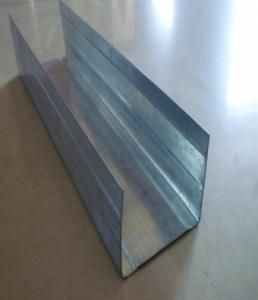

Galvanized Metal Studs And Tracks,Gypsum Drywall Metal Stud,Metal Studs Size

Suitable for construction and decoration, matched with gypsum board

With fire-resistant functi

Suitable for partition wall

Stud size options: 50 x 45, 50 x 40, 50 x 35, 75 x 25, 75 x 35, 75 x 45 and 100 x 45mm

Track size options: 50 x 40, 50 x 35, 75 x 30, 75 x 40 and 100 x 40mm

Length options: 2.95, 3.0, 5.95 and 6.0m

Thickness options: 0.35, 0.4, 0.45, 0.5, 0.6, 0.7 and 0.8mm

Features

Material

Galvanised steel

Zine Coated Level

60~270 g/m2 (depends on the customer's request)

Thickness

0.35~1.20mm

Features of light steel keel: high performance, easy cut apart, non-deforming, simply installation, dry construction, light weight and environment friendly

3.Image

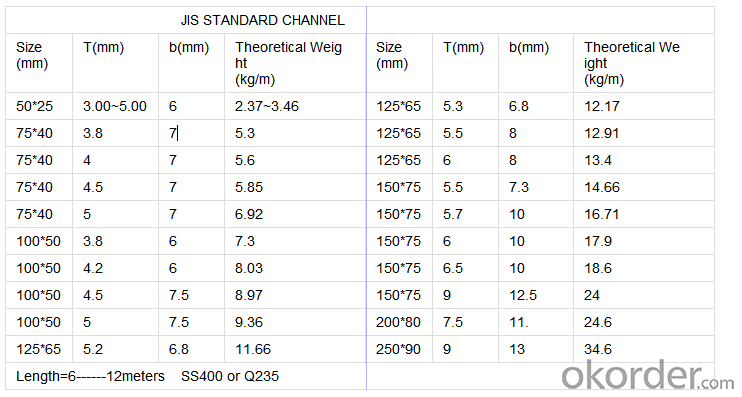

4.Detailed Specification

5.FAQ

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

- Q: Light steel keel wall to remove the price

- Fixed price: the state has a demolition quota, but the price is very low, generally can not afford to be fixed. Now some parts of the decoration quota also have to remove the sub-head, slightly higher than the demolition quota, but no profit.

- Q: 4 m long prefabricated board can do light steel keel double gypsum board wall?

- Yes, because the prefabricated board toughness is better, and its specifications are not the kind of chunks, if the chunk can withstand the weight will be reduced in the middle of the possibility of falling to increase .. Light steel keel wall itself The weight is not heavy, coupled with the ceiling is also force, then the weight of the ground will be reduced accordingly

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- With light brick wall, there are 1.5 and 1.2 the price is about 60 it

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Save material, reduce human input The use of the fixed screw of the keel and the angle of the fixed support column are used as the reinforcement of the ridge of the ridge, which changes the traditional construction method of embedding steel and fixed expansion bolts in the ridge, saving the material and reducing the manpower Of the input.

- Q: Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel life in humid environment Short brick block from the weight of large but because the single volume of small transport more convenient light partition board can be used for humid environment but a single volume upstairs is not convenient to install as light steel keel convenience The cost gap is not big

- Q: Can the gypsum board be painted on the wall

- Direct big screw can be because the back of the painting has a rope directly linked to such a simple question without the whole too much trouble

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- For the wall (or the top wall of the building), the distance between the vertical keel shall not be greater than 400mm, the distance between the transverse keel shall not be more than 600mm, and the fire gypsum board shall be used. Fixed, the upper edge of the gypsum board fixed on the top with the keel, the board from the floor should be greater than 20mm, and fire sealant with solid.

- Q: How to construct double - sided double gypsum board partition wall

- Vertical keel sub-file: According to the location of the wall defense door openings, in the installation of the top keel, according to the specifications of the panel panel width, sub-file size 450mm, less than the modulus of the file should avoid the first box Plate position, so that the edge of the gypsum cover panel is not out of the box. Installation of horizontal card keel: According to the design requirements, wall height greater than 3m should be added to the horizontal card retaining keel, mining core pulling rivets or screws tied to fixed

- Q: Light steel keel installed security door how loaded really

- Light steel keel its own strength is not very good, anti-theft door directly fixed on the light steel keel, then open the door will have a great impact on the light steel keel wall.

- Q: How to do woodworking partition wall, with door

- Wooden skeleton should use specifications for 40 mm × 70 mm red, from pine. The spacing of the keel should take into account the size of the panel, usually between 450 and 600 mm If there is a door, both sides should establish a vertical keel. The dragon keel should be connected with the lordel open rod, the window on the bottom and the top of the door should be installed along the horizontal keel installed along the ground, along the top wood Leng, the corners should be stretched into the brick at least l20 mm, To ensure that the partition wall and the original structure of the wall connected firmly.

Send your message to us

Galvanized Metal Studs And Tracks,Gypsum Drywall Metal Stud,Metal Studs Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords