GALVANISED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

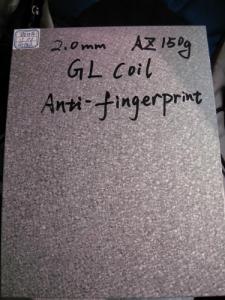

Hot Dipped Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Product Description Of Hot Dipped Galvanized Steel Coil

Thickness | 0.13mm-0.7mm |

Width | 600mm-1250mm |

Zinc Coating | 30-200g/m2 |

Internal Diameter | 508mm/610mm |

Coil Weight | 3-12MT |

Quality | commercial and structural quality |

Surface Treatment | regular & minimum spangle, zero spangle, oiled & dry, chromated , non-skin pass , skin pass |

Standard | JIS G 3302, ASTM A 653M, EN 10327 |

Steel Grade | SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Technical Data Of Hot Dipped Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Hot Dipped Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

- Q: What are the different methods of tempering steel coils?

- There exist numerous techniques for tempering steel coils, each possessing unique advantages and disadvantages. Some of the most prevalent techniques include: 1. Air cooling: This method, the simplest and most commonly employed, involves heating the coils to a specific temperature and allowing them to cool naturally in the surrounding air. Although relatively speedy and cost-effective, this technique can result in uneven cooling and may lack precise control over the final properties of the steel. 2. Water quenching: In this approach, the steel coils are heated and then rapidly cooled by immersing them in a water bath. Water quenching provides a swifter and more controlled cooling rate than air cooling, resulting in increased hardness and strength. However, it may also cause heightened distortion and the development of internal stresses in the steel. 3. Oil quenching: Similar to water quenching, this method entails immersing the steel coils in an oil bath to rapidly cool them. Oil quenching offers a slower and more uniform cooling rate in comparison to water quenching, leading to reduced distortion and internal stresses. Nevertheless, it yields slightly lower hardness and strength than water quenching. 4. Salt bath quenching: This technique necessitates immersing the steel coils in a heated bath of molten salt for rapid cooling. Salt bath quenching ensures an even and controlled cooling rate, resulting in improved hardness and strength compared to air or water quenching. However, it requires specialized equipment and may not be suitable for all steel types. 5. Induction hardening: In this method, the steel coils undergo induction heating before being rapidly cooled using air, water, or oil quenching. Induction hardening permits precise control over the heating and cooling process, thereby achieving specific hardness and strength properties in desired areas of the steel. Nonetheless, it demands specialized equipment and is generally employed for specific applications or sections of the steel coils. Ultimately, the choice of tempering method relies on various factors, including the desired properties of the steel coils, the type of steel employed, and the specific requirements of the end application.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q: How are steel coils used in the production of HVAC ducts?

- Steel coils are used in the production of HVAC ducts as they are rolled into a specific shape and size to form the main body of the duct. The coils are then cut and welded together to create a seamless and durable structure that can withstand the high temperatures and pressures associated with HVAC systems.

- Q: Can steel coils be rewound?

- Yes, steel coils can be rewound. Rewinding steel coils involves uncoiling the existing steel coil and then recoiling it to the desired specifications. This process is commonly done to adjust coil size, improve coil shape, or remove defects in the original coil. Rewinding steel coils allows for better quality control and ensures that the coils meet the specific requirements of the customer.

- Q: will peircers use surgical steel? how do you know for sure what they are using?

- DO NOT USE SURGICAL STEEL. Use IMPLANT GRADE stainless steel, or, even better, IMPLANT GRADE titanium. surgical steel is a marketing term, pioneered by a cutlery company to make their cutlery seem cleaner. So basically, surgical steel can be anything from the forks and knives in your house, to the rusty tools in the shed, whilst implant grade stainless steel is specifically made for medical uses in the body (pins in your foot or a pacemaker in your heart.)

- Q: What are the different methods of surface cleaning for steel coils?

- Some of the different methods of surface cleaning for steel coils include mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials, such as brushes or sandpaper, to physically remove dirt, rust, or other contaminants from the surface of the steel coils. Chemical cleaning involves the use of specific cleaning agents or solvents to dissolve or loosen dirt and contaminants from the surface. High-pressure water cleaning utilizes a powerful jet of water to remove dirt and debris from the steel coils. These methods can be used individually or in combination depending on the specific cleaning requirements and condition of the steel coils.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they provide the raw material for forming the enclosures' outer shells and structural components. The steel coils are processed and shaped through various techniques such as cutting, bending, and welding, to create the desired size and shape of the enclosure. The steel's strength and durability make it an ideal material choice for ensuring the enclosures can protect electrical equipment from environmental factors and provide safety for users.

- Q: What are the factors that affect the quality of steel coils?

- The quality of steel coils can be influenced by various factors. To begin with, the composition of the steel itself plays a vital role in determining its quality. Impurities like sulfur or phosphorus can have a negative impact on the strength, durability, and overall performance of the steel. Additionally, the quality of the steel is affected by its carbon content, alloying elements, and heat treatment. Furthermore, the quality of the steel coils is greatly affected by the manufacturing process and techniques utilized during production. Factors such as the cleanliness of the production environment, the precision of the rolling and cooling processes, and the control of temperature and pressure throughout manufacturing all contribute to the final quality of the coils. Additionally, the surface quality of the steel coils is a crucial factor. Any defects or imperfections on the surface, such as scratches, dents, or corrosion, can compromise the integrity and functionality of the coils. It is essential to handle, store, and transport the coils properly to maintain their surface quality. Moreover, the mechanical properties of the steel coils, including tensile strength, yield strength, and elongation, are essential indicators of their quality. These properties depend on various factors, such as the type of steel, its thickness, and the processing conditions. Lastly, external factors such as environmental conditions, like humidity and temperature, can affect the quality of steel coils. Exposure to moisture or extreme temperatures can lead to corrosion or other forms of degradation, impacting the overall quality and lifespan of the coils. In conclusion, the quality of steel coils is influenced by several factors, encompassing the composition of the steel, the manufacturing process, surface quality, mechanical properties, and external environmental conditions. It is crucial to carefully control and monitor these factors to produce high-quality steel coils that meet the desired specifications and standards.

- Q: gigantic navy ships made of steel float, why??

- Believe it or not - A steel boat floats for the exact same reason all boats float. And the very best - easy to understand explanation of this (with pictures) is at the link below.

- Q: What is the thickness range of steel coils?

- The thickness range of steel coils varies depending on the specific application and industry. However, generally speaking, steel coils can have a thickness range from as thin as 0.005 inches (0.13 mm) to as thick as 0.5 inches (12.7 mm) or more.

Send your message to us

GALVANISED STEEL SHEET

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords