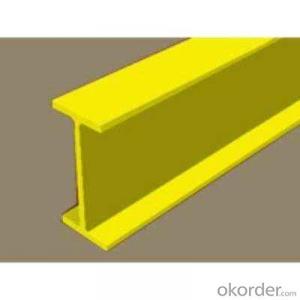

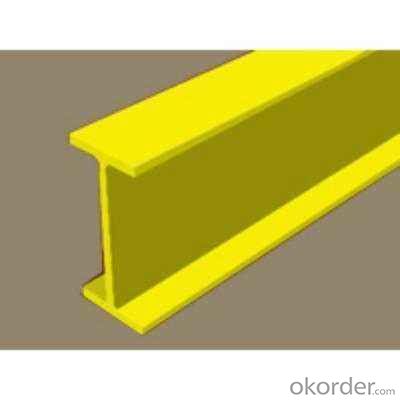

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

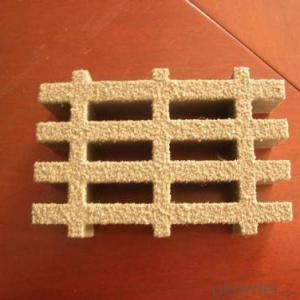

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: What is the shear strength of FRP pultrusion profiles?

- The shear strength of FRP (Fiber Reinforced Plastic) pultrusion profiles can vary depending on several factors such as the type and quality of fibers used, the resin matrix, and the manufacturing process. Generally, FRP pultrusion profiles have high shear strength due to the continuous fibers running along the length of the profile. The shear strength of FRP pultrusion profiles is typically determined through testing according to industry standards such as ASTM D2344 or ISO 14129. These tests involve subjecting the profile to a shear force until failure occurs, allowing for the calculation of the shear strength. The exact shear strength values for FRP pultrusion profiles can vary significantly depending on the specific composition and design of the profile. However, it is not uncommon for FRP pultrusion profiles to exhibit shear strengths in the range of 50-150 MPa (megapascals) or higher. This makes them suitable for a wide range of structural applications where shear forces are prevalent. It is important to note that the shear strength of FRP pultrusion profiles can be influenced by factors such as temperature, moisture, and exposure to chemicals. Therefore, it is essential to consider the specific environmental conditions and requirements of the application when determining the appropriate FRP profile to be used. Overall, FRP pultrusion profiles are known for their excellent shear strength, which contributes to their popularity and effectiveness in various industries such as construction, transportation, and infrastructure.

- Q: Can FRP pultrusion profiles be used in agricultural applications?

- Indeed, FRP pultrusion profiles are applicable in the field of agriculture. Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles are an ideal choice for a variety of agricultural uses. One common utilization of FRP pultrusion profiles in agriculture is the construction of livestock enclosures, encompassing fences, gates, and pens. These profiles possess outstanding resistance to weather conditions, chemicals, and degradation caused by UV rays, ensuring their long-lasting performance in outdoor environments. Furthermore, their lightweight composition facilitates ease of handling and installation. Moreover, FRP pultrusion profiles find application in the production of agricultural equipment and machinery. They can be employed for structural components, such as beams and supports, as well as functional parts like handles, brackets, and covers. The impressive strength of FRP profiles enables them to withstand heavy loads and challenging operating conditions, while their resistance to corrosion guarantees their longevity in corrosive surroundings such as fertilizer storage areas or livestock waste management systems. Additionally, FRP pultrusion profiles can be utilized for irrigation systems in agriculture. Their non-conductive nature renders them perfect for situations requiring electrical insulation, such as the creation of irrigation pipes or channels. Furthermore, the corrosion resistance of FRP profiles ensures their ability to endure exposure to water, chemicals, and fertilizers frequently employed in agricultural irrigation. To summarize, FRP pultrusion profiles exhibit exceptional suitability for agricultural applications due to their high strength, resistance to corrosion, and durability. Whether employed in livestock enclosures, agricultural machinery, or irrigation systems, FRP profiles offer numerous advantages that position them as a reliable choice within the agricultural industry.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Yes, FRP pultrusion profiles can be customized or tailored to specific project requirements. They can be designed and manufactured in various shapes, sizes, and configurations to meet specific project needs, such as load-bearing capacity, stiffness, corrosion resistance, and thermal properties. Customization options also include adding features like brackets, holes, or reinforcements to ensure the profiles are optimized for the intended application.

- Q: What are the quality control measures for FRP pultrusion profiles?

- Quality control measures for FRP pultrusion profiles involve a series of steps and processes to ensure the products meet the desired standards. These measures include: 1. Raw material inspection: The first step is to verify the quality of the raw materials used in the pultrusion process. This includes checking the properties and specifications of the fiberglass, resin, additives, and other components. 2. Process control: Throughout the pultrusion process, various parameters need to be monitored and controlled. This includes maintaining consistent temperature, pressure, and resin content during the impregnation, forming, and curing stages. 3. Sample testing: Regular sampling is conducted during production to assess the quality of the profiles. These samples are tested for mechanical properties, dimensional accuracy, and surface finish to ensure they meet the required standards. 4. Visual inspection: Each profile is visually inspected to identify any defects, such as cracks, voids, delamination, or surface imperfections. Visual inspection helps to identify any irregularities that may affect the structural integrity or aesthetics of the profiles. 5. Mechanical testing: Profiles are subjected to mechanical testing to assess their strength, stiffness, and other mechanical properties. This involves conducting tests like flexural testing, tensile testing, impact testing, and compression testing. The results are compared to the specified requirements to determine if the profiles meet the necessary standards. 6. Quality documentation: Proper documentation is maintained throughout the manufacturing process, including records of raw material specifications, process parameters, test results, and inspection reports. This ensures traceability and provides a reference for quality assurance. 7. Non-destructive testing: In addition to mechanical testing, non-destructive testing techniques, such as ultrasonic testing or X-ray inspection, may be used to identify internal defects or inconsistencies without damaging the profiles. 8. Quality audits: Regular internal and external audits are conducted to assess the effectiveness of the quality control measures and ensure compliance with relevant industry standards and regulations. By implementing these quality control measures, manufacturers can ensure that FRP pultrusion profiles meet the required specifications, resulting in reliable and high-quality products.

- Q: What raw materials do FRP pultrusion require?

- Fiber: pultruded glass fiber roving, continuous felt, stitch woven felt, stitch woven composite felt, fabric, glass fiber surface mat, polyester fiber surface felt, etc.;

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of highway guardrails. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for highway guardrails. They have a high strength-to-weight ratio, which means they can provide the necessary structural support while being much lighter than traditional materials like steel. This makes transportation, installation, and maintenance easier and more cost-effective. Secondly, FRP pultrusion profiles are corrosion-resistant. Unlike steel, which can rust over time due to exposure to harsh weather conditions, FRP does not corrode. This makes FRP guardrails durable and long-lasting, reducing the need for frequent repairs or replacements. Additionally, FRP pultrusion profiles are non-conductive, meaning they do not conduct electricity. This is an important safety feature for highway guardrails, as it eliminates the risk of electrical shock in case of accidents involving power lines or lightning strikes. Furthermore, FRP pultrusion profiles can be manufactured in various shapes and sizes to meet the specific requirements of highway guardrails. They can be designed to have the necessary stiffness and impact resistance to withstand the forces exerted by vehicles during accidents or collisions. In summary, FRP pultrusion profiles are a suitable material for the construction of highway guardrails due to their lightweight, corrosion-resistant, non-conductive, and customizable properties. They offer a cost-effective and durable solution that can contribute to improving safety on highways.

- Q: What are the features of Glass Fiber Reinforced Plastic Pultruded materials and chairs?

- Glass reinforced plastic extruded section bar has the characteristics of unlimited length, high utilization rate of raw material, corrosion resistance, good weatherability and long service life

- Q: Can FRP pultrusion profiles be used in the construction industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction industry. FRP pultruded profiles offer several advantages that make them suitable for various construction applications. Firstly, FRP pultrusion profiles are lightweight yet exceptionally strong. This makes them an excellent choice for construction projects as they provide high strength-to-weight ratio, reducing the overall weight of the structure while maintaining structural integrity. This can be particularly advantageous in applications such as bridges, walkways, and platforms. Secondly, FRP pultrusion profiles are highly corrosion resistant. Unlike traditional construction materials like steel or wood, FRP does not rust, rot, or corrode when exposed to harsh environmental conditions, chemicals, or moisture. This makes FRP profiles ideal for outdoor or marine applications where corrosion is a concern, such as seawalls, docks, or offshore structures. Additionally, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized, such as electrical enclosures or cable trays. FRP profiles also have low thermal conductivity, which can help improve energy efficiency in buildings by reducing heat transfer. Furthermore, FRP pultrusion profiles are highly durable and require minimal maintenance. They have a long service life and do not require regular painting, sealing, or treatment like traditional materials. This can result in significant cost savings over the life cycle of a construction project. Lastly, FRP pultrusion profiles can be designed to meet specific strength, stiffness, and dimensional requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in design and customization. This versatility makes FRP profiles suitable for a wide range of construction applications, including beams, columns, gratings, handrails, and structural components. In summary, FRP pultrusion profiles are a viable option for the construction industry due to their lightweight, high strength, corrosion resistance, electrical and thermal insulation properties, durability, low maintenance requirements, and design flexibility.

- Q: Are FRP pultrusion profiles resistant to hail or impact damage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to hail or impact damage. The combination of reinforcing fibers, such as carbon or glass, and a polymer resin matrix provides exceptional strength and durability to FRP pultrusions. These profiles have superior impact resistance compared to other materials like wood, steel, or aluminum. FRP pultrusion profiles are designed to withstand harsh environmental conditions, including hailstorms. The composite nature of FRP allows it to absorb and distribute impact energy, preventing the formation of cracks or fractures. This makes them an ideal choice for applications that require resistance to hail or impact damage, such as building facades, bridges, handrails, or utility poles. Furthermore, FRP pultrusion profiles have a high strength-to-weight ratio, meaning they can withstand heavy impacts without compromising their structural integrity. They are also non-corrosive, which makes them immune to rust or degradation caused by hail or impact. In summary, FRP pultrusion profiles are highly resistant to hail or impact damage due to their composite construction and excellent strength-to-weight ratio. They provide a reliable and long-lasting solution for applications that require durability and resistance to harsh environmental conditions.

Send your message to us

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords