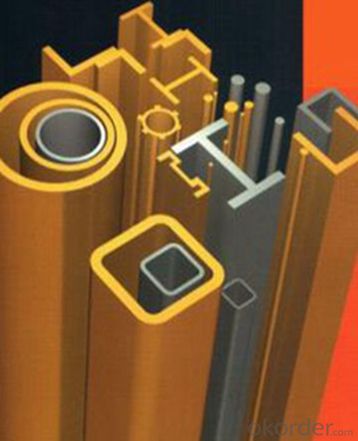

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

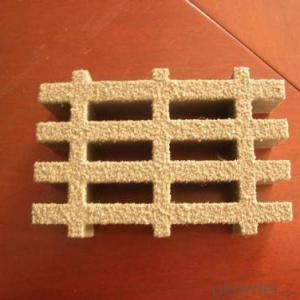

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

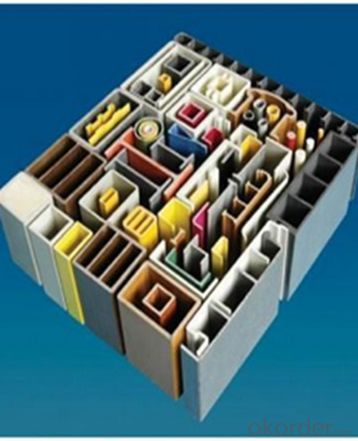

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenol resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

Q1.What's your sample policy?

A:We can supply the sample if we have ready parts in stock, but the customers have to pay the courier cost.

Q2.Can you produce according to the samples?

A: Yes, we can produce or modify the products according to your request.

Q3.How do you deliver the goods to my country?

A:We can provide international express, such as DHL, EMS, UPS, FedEx, etc. We select air freight and sea freight upon your requests. Quotations if without mentioning the shipping costs are shipping fee excluded.

Q4.How much does it cost to ship to my country?

A:When you goanna to place an order, please contact us, because different country has different freight.

Q5.How to get the catalogue?

A:please contact us and tell us what you are looking for.

We will try our best to meet customers' demands. Welcome you come here to visit us. We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

PICTURES

- Q: Can FRP pultrusion profiles be used in the production of electrical cabinets?

- FRP pultrusion profiles are certainly viable for incorporating into the manufacturing process of electrical cabinets. Their exceptional electrical insulating characteristics render them a fitting option for applications involving the creation of electrical cabinets. These profiles are non-conductive, thus granting insulation and safeguarding against electrical currents, ensuring the security of the electrical components encased within the cabinet. Furthermore, FRP pultrusion profiles boast a high strength-to-weight ratio, resistance to corrosion, and durability, making them a dependable choice for enduring electrical cabinets in diverse settings.

- Q: Can FRP pultrusion profiles be used in the construction of wind turbine blades?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of wind turbine blades. FRP pultrusion profiles offer several advantages that make them suitable for wind turbine blade construction. Firstly, FRP pultrusion profiles are lightweight yet strong, which is an important characteristic in wind turbine blades as they need to be able to withstand the aerodynamic forces exerted by the wind. The high strength-to-weight ratio of FRP pultrusion profiles allows for the construction of longer and more efficient blades. Additionally, FRP pultrusion profiles have excellent corrosion resistance properties, which is crucial for wind turbines exposed to harsh weather conditions. Unlike traditional materials like steel, FRP does not corrode, ensuring a longer service life for the wind turbine blades. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements. This flexibility allows for the optimization of blade performance by tailoring the shape, thickness, and stiffness of the profiles to maximize energy capture and minimize fatigue. Furthermore, FRP pultrusion profiles offer good fatigue resistance, meaning they can withstand repeated loading cycles without experiencing significant degradation in performance. This is essential for wind turbine blades that are subjected to cyclic loading due to wind gusts and changes in wind direction. Finally, FRP pultrusion profiles are also electrically non-conductive, which is advantageous for wind turbine blades as it eliminates the risk of electrical discharge during operation. Overall, the lightweight, strong, corrosion-resistant, and customizable nature of FRP pultrusion profiles make them an excellent choice for the construction of wind turbine blades, contributing to the development of more efficient and durable wind energy systems.

- Q: Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Indeed, wastewater treatment tanks can effectively utilize FRP pultrusion profiles. These profiles are renowned for their exceptional strength-to-weight ratio, resistance to corrosion, and longevity, making them an optimal option for harsh environments such as wastewater treatment facilities. To manufacture FRP pultrusion profiles, continuous fibers like glass or carbon are drawn through a resin bath and subsequently through a heated die to attain the desired shape. This process yields profiles with consistent cross-sections and outstanding mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can serve various purposes. They can function as structural components, like beams, columns, and bracing systems, offering the necessary strength and rigidity to support the tank structure. Additionally, FRP profiles can reinforce concrete structures, bolstering their durability and resistance against chemical attack from the wastewater. Moreover, FRP pultrusion profiles can be engineered to endure the corrosive impact of the chemicals and gases found in wastewater treatment tanks. Unlike conventional materials such as steel or concrete, FRP exhibits a high resistance to corrosion, guaranteeing an extended service life and reduced maintenance expenses. Furthermore, FRP profiles provide advantages in terms of installation and transportation. They are lightweight, enabling easier handling and diminished labor requirements during construction. The modular nature of FRP profiles also facilitates swift assembly and disassembly, simplifying maintenance and modifications. Overall, incorporating FRP pultrusion profiles in the construction of wastewater treatment tanks offers numerous benefits, including superior strength, corrosion resistance, durability, and ease of installation. These advantages render FRP a dependable and cost-effective choice for wastewater treatment facilities.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of chemical pumps?

- Chemical pumps can benefit from the use of FRP pultrusion profiles. These profiles, composed of a combination of fiber reinforcements and a polymer resin matrix, offer numerous advantages that make them ideal for this manufacturing process. To start, FRP pultrusion profiles are highly resistant to corrosion. Chemical pumps often encounter corrosive substances that can cause damage to traditional metal components. However, the composition of FRP profiles allows them to withstand the corrosive effects of various chemicals. This durability ensures that chemical pumps remain functional and reliable for extended periods. Moreover, FRP pultrusion profiles possess impressive mechanical properties. Their strength-to-weight ratio means that they can handle high pressures and loads without adding excessive weight to the pump. This is especially important for chemical pumps that must perform heavy-duty tasks while maintaining their efficiency over time. Furthermore, FRP pultrusion profiles offer flexibility in design. Manufacturers can produce these profiles in different shapes and sizes, allowing for customization that meets specific pump requirements. This adaptability enables manufacturers to optimize the performance and efficiency of chemical pumps. Additionally, FRP pultrusion profiles are non-conductive, minimizing the risk of electrical accidents in chemical pump applications. This safety feature is crucial in ensuring a secure working environment. In conclusion, FRP pultrusion profiles are an excellent choice for manufacturing chemical pumps. Their corrosion resistance, exceptional mechanical properties, design flexibility, and electrical non-conductivity contribute to the longevity, efficiency, and safety of these pumps in various industrial settings.

- Q: Can FRP pultrusion profiles be customized or tailored to specific project requirements?

- Indeed, FRP (Fiber Reinforced Polymer) pultrusion profiles have the capability to be customized or tailored according to the specific demands of a project. The process of pultrusion, which is employed in the manufacturing, enables the creation of continuous fiber-reinforced composite profiles while providing a considerable amount of design flexibility. By adjusting the design and manufacturing parameters, the dimensions, shapes, and mechanical properties required by a project can be accommodated. The customization procedure commences with a comprehension of the project's needs and specifications. This involves identifying the desired profile dimensions, cross-sectional shape, and mechanical properties such as strength, stiffness, and durability. Based on these requirements, engineers and manufacturers can devise a personalized solution. The customization of FRP pultrusion profiles can be accomplished through various methods. Firstly, the selection of reinforcement materials, such as fiberglass, carbon fiber, or aramid fiber, can be made based on the desired mechanical characteristics. The orientation and volume fraction of the fibers can also be adjusted to optimize the strength and stiffness of the profile. Additionally, the resin matrix utilized in the pultrusion process can be customized to enhance specific properties like fire resistance, chemical resistance, or UV resistance. To meet the project's requirements, different resin systems including polyester, vinyl ester, or epoxy can be utilized. Furthermore, during the manufacturing process, the pultrusion method allows for the incorporation of additional features. This includes the addition of inserts, fastener holes, grooves, or other structural details to the profile. These modifications can be tailored to the specific project requirements, ensuring compatibility with the overall design and assembly. In conclusion, FRP pultrusion profiles offer a significant level of customization and tailoring to cater to the specific demands of a project. This versatility has made them a favored choice in various industries such as construction, infrastructure, aerospace, and automotive, where lightweight, durable, and corrosion-resistant materials are essential.

- Q: Can FRP pultrusion profiles be used in cooling towers?

- Cooling towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantages that make them suitable for such applications. To begin with, the corrosion resistance of FRP pultrusion profiles is exceptional, a crucial attribute in a cooling tower setting where exposure to water and chemicals is commonplace. Unlike conventional materials like steel, FRP pultrusion profiles do not rust or corrode, ensuring a longer service life and reduced maintenance expenses. Secondly, FRP pultrusion profiles exhibit a high strength-to-weight ratio, rendering them lightweight yet sufficiently robust to meet the structural demands of cooling towers. This facilitates easier installation and transportation, ultimately reducing the overall project costs. Thirdly, FRP pultrusion profiles boast excellent thermal insulation properties. As cooling towers involve the transfer of heat from water to the surrounding air, the thermal insulation provided by these profiles enhances the efficiency of the cooling process. Lastly, FRP pultrusion profiles are highly customizable and can be tailored to meet the specific requirements of cooling tower applications. They can be engineered to possess various shapes, sizes, and dimensions, ensuring a precise fit for the cooling tower design. Overall, FRP pultrusion profiles represent a dependable and cost-effective choice for cooling tower applications. Their corrosion resistance, high strength-to-weight ratio, thermal insulation capabilities, and customization options make them an excellent option.

- Q: Are FRP pultrusion profiles resistant to electromagnetic interference?

- Yes, FRP pultrusion profiles are generally resistant to electromagnetic interference (EMI). The use of fiberglass reinforced plastic (FRP) in pultrusion profiles provides excellent electrical insulation properties, which help to minimize the effects of electromagnetic interference. Unlike metals, which are conductive and can easily transmit electrical signals, FRP materials have high dielectric strength and low electrical conductivity. This makes FRP pultrusion profiles less susceptible to EMI and allows them to act as barriers to electromagnetic waves. Additionally, FRP materials can be further enhanced with additional layers or coatings to increase their EMI shielding effectiveness if required. Overall, FRP pultrusion profiles are a reliable choice for applications where resistance to electromagnetic interference is important.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of theme park rides. FRP pultrusion profiles offer several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are lightweight yet strong, making them ideal for constructing ride structures that need to withstand dynamic loads and forces. Their high strength-to-weight ratio allows for the creation of large, complex structures that can support the weight of riders and withstand the forces generated during operation. Additionally, FRP pultrusion profiles are corrosion-resistant, which is crucial for theme park rides that are often exposed to outdoor environments, including moisture, chemicals, and UV radiation. This corrosion resistance ensures that the ride structures remain durable and safe over their lifespan, reducing the need for costly maintenance and repairs. Another advantage of FRP pultrusion profiles is their design flexibility. They can be easily molded into various shapes and sizes to meet the specific requirements of theme park ride designs. This versatility allows for the creation of unique and visually appealing ride structures that enhance the overall experience for park visitors. Furthermore, FRP pultrusion profiles offer excellent electrical insulation properties, which can be essential for rides that involve electrical components or systems. This insulation helps to minimize the risk of electrical hazards and ensures the safety of riders and operators. In conclusion, FRP pultrusion profiles are well-suited for the construction of theme park rides due to their lightweight, high strength, corrosion resistance, design flexibility, and electrical insulation properties. These profiles can contribute to the development of safe, durable, and visually appealing ride structures that enhance the enjoyment and excitement of theme park visitors.

- Q: How do FRP pultrusion profiles compare to traditional building materials?

- FRP pultrusion profiles offer numerous advantages over traditional building materials. They are lightweight yet incredibly strong, providing high structural integrity. These profiles are resistant to corrosion, chemicals, and UV radiation, ensuring long-term durability. Additionally, FRP pultrusion profiles have excellent insulation properties, making them ideal for various applications. They are also easy to install, require minimal maintenance, and are cost-effective in the long run. Overall, FRP pultrusion profiles outperform traditional building materials in terms of strength, durability, versatility, and efficiency.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy and solar power industry. FRP pultrusion profiles possess several key characteristics that make them ideal for such applications. Firstly, FRP pultrusion profiles have high strength-to-weight ratio, meaning they are lightweight yet strong, which is crucial in the renewable energy sector where materials need to withstand various environmental conditions while being cost-effective. Secondly, FRP pultrusion profiles offer excellent corrosion resistance, ensuring durability and longevity in outdoor and potentially corrosive environments, such as solar power plants or wind farms. Additionally, these profiles have excellent electrical insulation properties, making them suitable for electrical applications commonly found in the renewable energy industry. Moreover, FRP pultrusion profiles can be easily customized into various shapes and sizes, enabling the design and engineering of complex structures required for solar power installations or wind turbine blades. Furthermore, FRP materials are non-conductive and non-magnetic, making them safe for use in electrical and magnetic fields associated with renewable energy systems. Overall, FRP pultrusion profiles offer a combination of strength, durability, lightweight, corrosion resistance, and electrical insulation properties that make them highly suitable for use in the renewable energy and solar power industry.

Send your message to us

FRP Pultrusion Profiles with Excellent Electromagnetism Property and Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 300000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords