Flat Trough Roller Idler

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 5000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

conveyor roller standard

|

Standard |

DIN15207, DIN22107, ISO1537, GB10595 |

|

Certificate |

ISO, CE |

|

Type conveyor |

DTII, TD75 |

|

Bearing NO |

6204/6205//6306/6307/6308 etc |

|

Material |

carbon steel, Rubber , nylon etc. |

|

Belt width |

from 300mm to 2000mm |

|

The international Market |

Middle east, South America, Africa, Southeast Asia. Etc. |

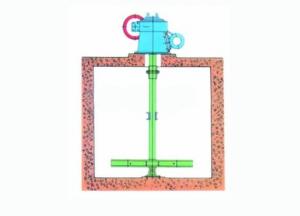

conveyor roller inner structure and material:

|

Roller inner structure and material: | |

|

Tube |

carbon Steel |

|

Shaft: |

bright drawn steel to required bearing tolerance |

|

Shaft end |

both ends of the tube are simultaneously machined and chamfered. |

|

Bearing |

single and double row deep groove ball bearing 2Z and 2RS with C3 clearance. |

|

Rubber |

heat vulcanized rubber. Wear resistant, anti-fire |

|

Seals |

multiple labyrinth seal |

|

Welding |

mixed gas shielded arc welding end. |

|

We aslo can product any kind as per your drawing! (TD75/DTII/CEMA, and so on). | |

conveyor roller size

|

Idler Dia mm |

50 |

63.5 |

76 |

89 |

102 |

108 |

114 |

127 |

133 |

139.8 |

152.4 |

159 |

165.2 |

177.8 |

190.7 |

194 |

219 |

|

length |

190mm3500mm | ||||||||||||||||

conveyor roller Advantages:

Life time: more than 30000 hours.

Multiple labyrinth seals , dust and water proof.

Excellent life time lubricating property.

- Q: How to weld the belt on the belt conveyor belt broken, and how to get the most reliable?

- If the drive belt is long enough to overlap and then drill holes are tightened with screws

- Q: Is the design of a conveyor belt, do not know the motor on the conveyor belt to choose how much power, who can give more detailed answer

- Motor and reducer are provided by the state

- Q: I have two sets of conveyor belt, cylinder and air compressor, the trachea are connected. The existing JS14P time relay 1, CJX2-1210 contactor 2, are AC220V, diffuse photoelectric switch 1 [2 lines often open 220V], how to wiring? Puzzled line of their own, but there is a contactor will be baffled, how to solve, how to properly wiring. Urgent thanks! Question added: I would like to ask which master can draw a picture really thank the younger brother

- I remember the sensor can be connected to the back of the electrical

- Q: Is the washing machine always grinding the belt?

- Do you say that the belt is the belt on the gear unit? Is it possible to install the tension is not enough brand? Suggested to the relevant after-sales consultation about.

- Q: To design a conveyor belt, 2 m / min, 3 m long, used to send the PCB board, very light, that is, do not know the choice of the motor, what about the power, and the wheel is not casually size, , The motor to add the inverter, or gear motor, or electronic regulator? Which is more suitable, why? Can you tell me Do not copy some online have to perfunctory! Thank you! More

- The load is not much motor 1KW enough. With the gear ratio to achieve the speed you can can be, with the inverter and reducer relative costs will be a little more. Speed does not need the same frequency converter.

- Q: If there is a conveyor belt, use a smaller force to push the gear so that the other side of the larger force of the gear rotation

- Hello, you describe the process it is a deceleration principle, with the drive that is called the pulley or called the drive wheel or driven wheel is not a gear, as shown in Figure: You mean that the small pulley turns when the big pulley turns, At this time set the drive wheel, as long as the drive wheel (small) installed motor drive motor drive can drive a large pulley. Leave you can explain in detail to help you.

- Q: How to determine the direction of friction in the conveyor belt problem? For example, an object from the oblique conveyor belt down, the belt clockwise movement, then what direction of friction, how to judge? The same circumstances, if it is counter-clockwise movement, what is the direction of friction? Seek advice! More

- The direction of friction and the direction of movement in the opposite direction, if the belt occurs on the sliding, the friction is the opposite direction of sliding, regardless of whether the conveyor belt rotation relative to the conveyor belt is still, the friction is the direction of rotation of the conveyor belt

- Q: Single mouth Ma machine conveyor belt broken, but do not know how to put the conveyor back more

- I do not need to screw off, it is very troublesome! I installed very simple. Minutes less than to get. But do not know how to say. You add me to say it !! I find a machine to record a video to you!

- Q: The motor has a fixed diameter wheel, connecting the conveyor belt. Conveyor belt with a large round of walking slow, or with a little bit of the wheel to go slow?

- The speed of the conveyor belt is determined by the speed of the wheels and the motor on the motor

- Q: What is the motor in the conveyor belt (pipelined) The kind of motor also has a speed control box, but not the inverter.

- Asynchronous motor. Synchronous motors are used in this place

1. Manufacturer Overview

| Location | Hengshui, China |

| Year Established | 2003 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia; Domestic Market |

| Company Certifications | Quality Credit AAAAA Brand Enterprise; Qualified Certificate; Outstanding Leader; Entrepreneurial model |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 50,000-100,000 square meters |

| No. of Production Lines | 4 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Flat Trough Roller Idler

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 5000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords