Fiberglass Mesh Tape for Ducts - Glass Fiber Mesh for Marble/Mosaic Slabs Reinforcement, 75gr

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Specifications of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75grPlace of Origin: China (Mainland)

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Brand Name: CMAX

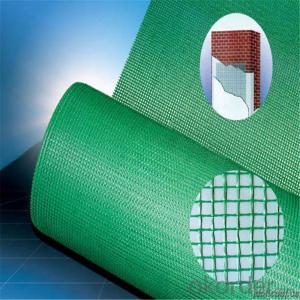

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75grApplication: Wall Materials

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Width: 1M-2M

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Size: 5*5/ INCH

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Weight: 40gsm to 200gsm

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Weave Type: Plain Woven

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Yarn Type: C-Glass

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Alkali Content: Medium

Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr Standing Temperature: 500℃

Product information of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Name: Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Use best fiberglass yarn and best glue

Clear and beautiful Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

High strength Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

30 years experience of manufacturing Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Excellent Priced Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

FAQ of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr

Q: What is Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Coated Alkali-resistant Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Four years under normal weather conditions and use .

Q: What is the package of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Package: rolls are packed into cartons or pallets.

Packing volumes: 200000m2/40HQ.

Q: Wow long about the production periods of Glass Fiber Mesh, Marble /Mosaic Slab Reinforcement, 75gr?

Production periods: 10days for 1X40HQ.

- Q: In what circumstances do you need to paste the mesh, if not, it is okay?

- Mesh is used in external wall thermal insulation building, it will not have a "thermal bridges" or "cold bridges" phenomenon, which has a good effect on building energy efficiency. It is toasted by the construction! In winter, when indoor heat through the mesh wall insulation materials will be isolated and preserved, and when the room temperature drops down, the heat of wall will be released, so as to adjust the indoor temperature; in summer, exterior mesh insulation will also prevent the sun's heat radiation and external incoming interior, so as to keep warm in winter and cool in summer of the building indoor environment, residential indoor environment and physical performance have been significantly improved.

- Q: The difference between wet and dry gridding cloth for external wall thermal insulation

- With glass fiber woven fabric as base material, gridding cloth is dipped in and coated with highly resistant polymer emulsion, thus featured by good alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft. It is widely used for thermal insulation, water proofing and crack resistance of internal and external walls of buildings. With alkali or alkali free glass fiber yarn as raw material and woven glass fiber gridding cloth as the base material, exterior wall thermal insulation gridding cloth (glass fiber grid cloth) is a new type of alkali product made by coating acrylic copolymer liquid and drying. It is featured by stable structure, high intensity, good alkali resistance, anti-corrosion, crack resistance, best enhancing effect, easy construction and operation. It is a kind of new building materials for thermal insulation of external walls and mainly used for internal and external surface reinforcement and crack resistance in cement, gypsum, walls, buildings and other structures.

- Q: The difference between glass fiber and plastic fiber screen

- Glass filter and PP filter (or other chemical compound) in glass filter just rely on the barrier (collision interception and sieve effect) is the chemical fiber, electrostatic adsorption (and not completely reliable test of electrostatic adsorption accounted for a large).

- Q: Mesh is the same thing with glass fiber cloth ?

- Platinum pot mesh fabric is a mixture of gray fabric knitted by platinum pot yarn and baken plastic, then what is the pot of gold yarn? It is the yarn drawn from pure platinum, then woven into fabric gold pot, combined with glue in the oven under a temperature of 200-500 degrees,and then baken into platinum pot mesh! The quality of pure platinum pot mesh can reach national standards! It looks beautiful and has an even mesh holes. - Di Xiang Mesh in Anping County - it is fireproofing,anti-cracking and heat insulated. It is difinitely the first choice of customers. The industrial glass fiber of pure platinum pot mesh glass fiber products is mainly used for pipeline corrosion, insulation flue {flues}, Continental, light panels, murals sandstone, glass, steel products and other gypsum GRC cement components and insulation board composite plate board walls, etc.

- Q: Glass fiber gridding cloth is easy to be broken after being glued.

- The glue matters or the baking process matters.

- Q: What purposes do dry-type transformers epoxy resin mesh have ?

- 1, the product adopts high quality, wax-free, E-glass and electric fiber yarn as the substrate, knitted into a variety of mesh cloth, and is made through heat drying dehydration, and then impregnated with epoxy resin mixture unique formula, dispensing glue under moderate temperature, and heat drying curing. 2, according to the property of the impregnated resin, the products can be divided into solvent and solvent-free mesh mesh. The main differences between the two mesh are as follows: 2.1, impregnated resin is different: Solvent Mesh contains acetone, solvent-free mesh is pure resin. 2.2, different procedures of impregnation: Solvent mesh is impregnated at normal temperature air, and it is opaque; while solvent-free mesh is impregnated under the medium-temperature vacuum pressure, and the mesh is transparent. 2.3, containing different amounts of plastic: The proportion of resin contained in solvent-free mesh is much larger than a solvent mesh, about twice of the solvent mesh. 2.4 application is different: Solvent-free mesh is suitable as an insulating layer between the coils with no partial discharge at very high field intensity the use of solvent-free mesh can reduce the thickness of the interlayer insulation.

- Q: As for the latitudinal tension and longitudinal tension of alkali resistant glass fiber gridding cloth, which is larger?

- The latitudinal yarn strength is larger than longitudinal yarn strength. (The latitudinal refers to the width of gridding cloth.)

- Q: Is it necessary to add 2 times of alkali resistant fiberglass mesh on the first floor?

- Alkali resistant glass fiber mesh cloth, external wall external insulation layer of reinforced materials, the main role is to: improve the mechanical strength of the surface layer, in order to ensure the continuity of the surface resistance of the surface layer of the dispersed shrinkage of the pressure and stress of insulation, to avoid stress concentration caused by the surface properties and anti crack. The changes of temperature and humidity, unexpected effects. Play an important function and role in the system of the alkali resistant glass fiber mesh insulation, an important part of the selection of the glass fiber net exterior insulation system is also a very good quality.

- Q: The thermal insulation hardware cloth and the Mesh, which is better?

- The external wall insulation is an insulation layer for indoor's insulation requirements. The raw material of the the insulation layer of the wall coverings insulation has a good performance of alkali resistance and an appropriate price, so it is a common choice of the mass. It can only play a certain alkali building insulation effect on the overall robustness of the building and do not have much effect. The walls of the high floor are usually the steel mesh through the welding process. It is made of the materials of iron wire, galvanized wire, mild steel wire and the surface process of mopping, galvanizing(heating and colding plate) to achieve the capacities of anti-errosion and anti-alkali.

- Q: Powder modified asphalt polyester blanket is a lower quality waterproofing material made of powder instead of polymer. Glass fiber gridding cloth reinforced waterproof coiled material uses waterproof coiled material as base

- Glass fiber gridding cloth reinforced waterproof coiled material Waterproof coiled material Difference: the quality of polyester reinforcement is higher than fiberglass reinforcement.

Send your message to us

Fiberglass Mesh Tape for Ducts - Glass Fiber Mesh for Marble/Mosaic Slabs Reinforcement, 75gr

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords