Fiberglass Mesh for Parging - 4x4 Mesh Roll Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Mesh Roll Reinforcement 4*4

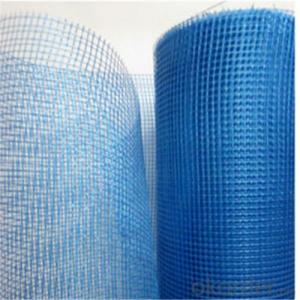

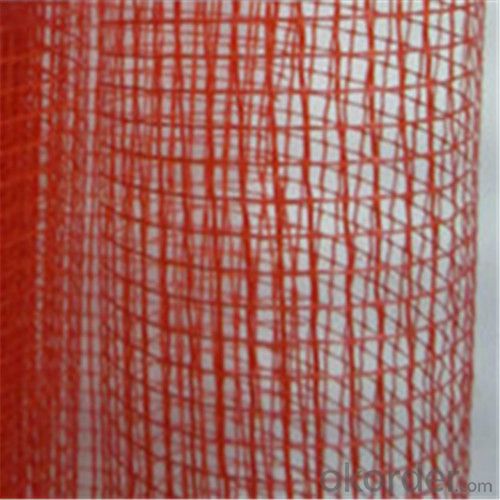

Fiberglass Mesh Roll Reinforcement 4*4 is mainly alkali-resistant fiberglass fabric, use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

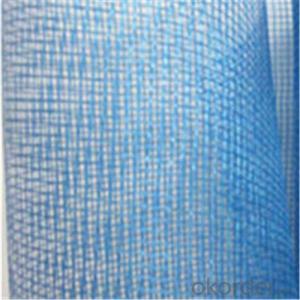

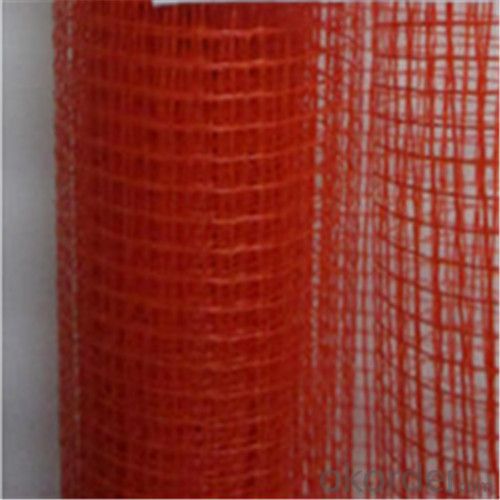

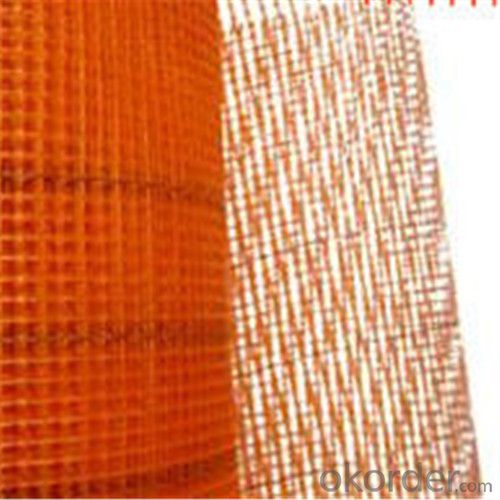

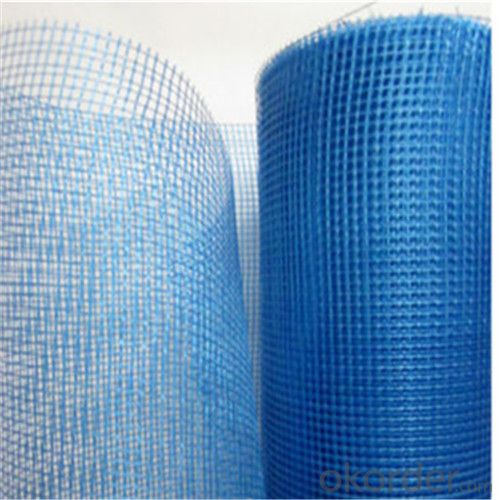

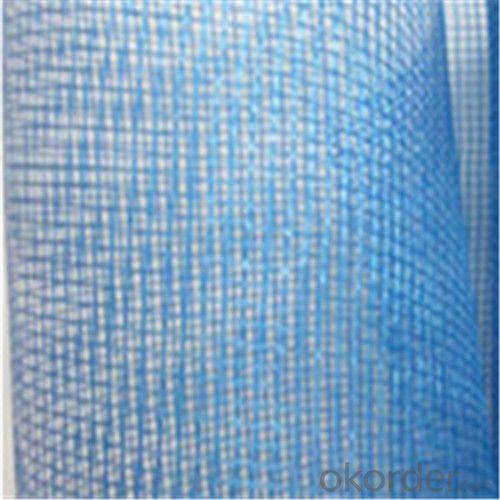

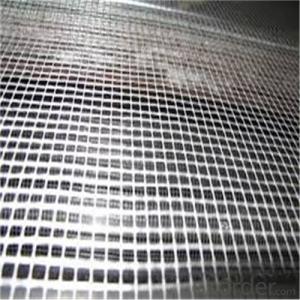

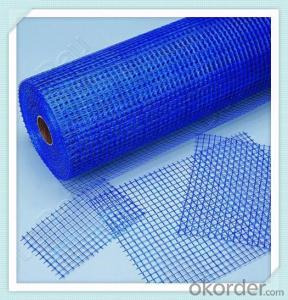

Image of Fiberglass Mesh Roll Reinforcement 4*4

Quick Detail of Fiberglass Mesh Roll Reinforcement 4*4

FOB Price of Fiberglass Mesh Roll Reinforcement 4*4: US $0.21 – 0.32 / Square Meter

MOQ of Fiberglass Mesh Roll Reinforcement 4*4: 5000 Square Meters

Supply Ability of Fiberglass Mesh Roll Reinforcement 4*4: 2000000 Square Meters per Month

Loading Port of Fiberglass Mesh Roll Reinforcement 4*4: CHINA MAIN PORT

Payment Terms of Fiberglass Mesh Roll Reinforcement 4*4: L/C, T/T

Specifications of Fiberglass Mesh Roll Reinforcement 4*4

Fiberglass Mesh Roll Reinforcement 4*4 Place of Origin: China (Mainland)

Fiberglass Mesh Roll Reinforcement 4*4 Brand Name: CMAX

Fiberglass Mesh Roll Reinforcement 4*4 Application: Wall Material, Marble Slab Reinforcement

Fiberglass Mesh Roll Reinforcement 4*4 Width: 1M-2M

Fiberglass Mesh Roll Reinforcement 4*4 Size: 5*5/ INCH, 4*4/ INCH, 4*5/ INCH

Fiberglass Mesh Roll Reinforcement 4*4 Weight: 40gsm to 200gsm

Fiberglass Mesh Roll Reinforcement 4*4 Length/ roll: 50m-100m, Special spec can be customized

Fiberglass Mesh Roll Reinforcement 4*4 Weave Type: Leno, Plain Woven

Fiberglass Mesh Roll Reinforcement 4*4 Yarn Type: C-Glass, E-Glass

Fiberglass Mesh Roll Reinforcement 4*4 Alkali Content: Medium Alkali

Fiberglass Mesh Roll Reinforcement 4*4 Standing Temperature: 500℃

Packing and Delivery of Fiberglass Mesh Roll Reinforcement 4*4

Package: Each Fiberglass Mesh Roll Reinforcement 4*4 roll is wrapped in a shrink bag, then put into containers

Packing Volumes: : 45000-50000m2/ 20FCL, 110000m2/ 40HQ, etc..

Delivery: About 15 days after confirming the order of Fiberglass Mesh Roll Reinforcement 4*4

Application/Usage of Fiberglass Mesh Roll Reinforcement 4*4

A. Wall reinforced material:

Fiberglass wall mesh, GRC wall panels,

EPS insulation with the wall board,

Gypsum board, Bitumen etc

B. Reinforced cement products.

C. Used for Granite, mosaic, marble back mesh etc.

D. Fabric waterproof membrane, asphalt roofing.

E. Framework material for reinforced plastics, rubber products,.

F. Fire board.

G. Grinding wheel base fabric.

H. Road surface geogrid.

I. Construction caulking tape etc.

FAQ of Fiberglass Mesh Roll Reinforcement 4*4

Q: What is Fiberglass Mesh?

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the main application of Fiberglass Mesh Roll Reinforcement 4*4?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh Roll Reinforcement 4*4?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh Roll Reinforcement 4*4?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh Roll Reinforcement 4*4?

A. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

B. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

C. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

D. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

E. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

F. Good impact resistance and not easy to be teared

- Q: What standard of CE certification should be done for fiberglass mesh fabric?

- Fiberglass mesh exports to the EU must provide CE certification, generally carried out in accordance with the CPR directive.

- Q: Is the wall plastering glass fiber net and hanging steel wire net the same function? Is it possible to choose one of them?

- Then, the external wall is covered with steel wire net insulation, so that both internal and external walls are used, for construction, the two are essential, not only a kind of

- Q: Interior mesh is same to the exterior?

- The price is not same. Interior wall is generally 0.58 yuan per meter; the aperture is 0.6; external wall is 120 g; 0.77 yuan per meter; 130 grams 0.82 yuan; 140 g 0.87; 160 grams 1.12 yuan per meter

- Q: Mesh and fiberglass cloth, which is better?

- It chiefly depends on your purpose because they are different.

- Q: External thermal insulation is using alkali-resistant mesh: does the fracture stress is the same with breaking elongation

- confirming the node has the potentiation to the tensile breaking strength of mesh, analyzing the influence factor to the alkali resistant breaking strength; measuring and testing the node strength of the mesh. from the test result we know that the alkali resistant coating has a certain reinforcement to the mesh tensile breaking strength. through the comparison of the the alkali resistant coating mesh soaking in the alkali resistant mesh alkali liquor, and the alalysis of the SEM atlas and the test of the tensile breaking strength, the friction force of the fibers and the quality of alkali resistant coating surface. the mesh alkali resistant tensile breaking strength is mainly determined by the glass fiber tensile breaking strength.

- Q: What is the construction method of external wall thermal insulation mesh

- I. Construction conditions: 1, the base wall is qualified by check and acception. Door and window frames, various family sevice line on the walls, downspouts bracket and built-in fitting are installed in the design. 2, the flatness of shear walls is checke by 2m guiding rule, when the maximum deviation is greater than 4, it should be leveled up by 20 thickness of 1: 3 cement mortar; when the maximum deviation is less than 4, it should be repaired and leveled up by 1: 3 cement mortar at the uneven place. 3, masonry walls should be leveled up by 20 thickness with 1: 3 cement mortar. 4, and the base wall and screed-coat should be dry. 5, the construction site ambient temperature and the wall surface temperature within 24 hours after the construction are not less than 5 ℃, the wind is not more than five class.

- Q: modified asphalt polyester and glass?fiber mesh strengthening waterproof roll is made of the good performance composite tyre.

- modified asphalt polyester is one kind of low quality waterproof roll which using the gelatine powder to take the place of high polymer. glass?fiber mesh reinforced waterproof roll is distinguished by the waterproof roll texture of the tyre

- Q: The costs of posting mesh are reasonable?

- It is mentioned to stick mesh in the construction technology which is included in the unit price. But in the process of construction, the foreman insisted on separate charge for the cost of the mesh, this is reasonable? T The process content in the Contract is as follows : 1: cleaning brush metope beauty solid nest wall again, 2: the nest bottom paint plaster leveling, 3: brush the nest wall fixed grid cloth, 4: the nest easily shave - 400, 2-3 times, 200 - watt bulb light and grinding smooth, brush primers, 5: Excluding special wall treatment, such as required gray sand leveling, the cost of another 15 yuan per square meter. 6: This offer provides paint, roller, brush wool and other disposable utensils from Party A. 7: To paint additive color is no more than two colors, one color for each additional should plus $ 150.

- Q: Why glass curtain cloth is used in super high-rise stone curtain wall?

- Many stone due to the existence of natural fracture, the cutting plate is easy to crack damage, formation of waste. Glue adhesive from the crack can be used to make the stone is a way of using stone penetration glue, but for the largest production with artificial watering penetration glue is much lower efficiency

- Q: Fiberglass mesh is poor in sizing and softness. The generally used glue is acrylic?acid emulsion. For better sizing, what auxiliary material should be added? Soft

- Acrylic emulsion is inappropriate, so you can choose a right emulsion.

Send your message to us

Fiberglass Mesh for Parging - 4x4 Mesh Roll Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords