Fiberglass Mat Tissue Woven Roving Combo Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

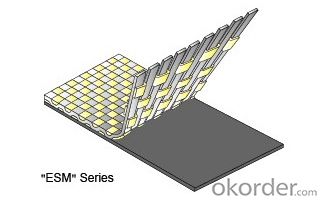

E-Glass Woven Roving Combo Mat is a complex mat made by stitching together woven roving and a layer of distributed chopped strand. Its main specification is woven roving (300g/m2~900g/m2) with chopped strands (50g/m2~500g/m2)。 The product has a maximum width of 110 inches. This product can be used for boat manufacturing.

2.Product Structure

3.Product Specifications

Product No | Overall Density | Woven Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | |

ESM1808 | 896.14 | 612 | 274.64 | 9.5 |

ESM1810 | 926.65 | 612 | 305.15 | 9.5 |

ESM1815 | 1080.44 | 612 | 457.73 | 10.71 |

ESM2408 | 1132.35 | 847 | 274.64 | 10.71 |

ESM2410 | 1162.86 | 847 | 305.15 | 10.71 |

ESM2415 | 1315.44 | 847 | 457.73 | 10.71 |

EMC2430 | 1762.71 | 847 | 900 | 15.71 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is quite high due to its inherent properties and construction. Fiberglass mat tissue is composed of fine glass fibers that are randomly arranged and bonded together with a binder material. This arrangement creates a strong and flexible mat that can withstand impacts and external forces. The random orientation of the glass fibers allows for the distribution of stress and energy across the entire mat tissue. When an impact is applied, the fibers absorb and disperse the force, preventing it from being concentrated in one area. This property helps to minimize the risk of cracks, fractures, or failures in the material. Additionally, the binder material used in fiberglass mat tissue provides further reinforcement and cohesion to the structure. It acts as a bonding agent, keeping the glass fibers in place and enhancing their overall strength. This bonding ensures that the mat tissue remains intact and resilient even under high impact loads. Due to its excellent impact resistance, fiberglass mat tissue is commonly used in various applications where durability and strength are essential. It is often utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics (FRP), to enhance their impact resistance and structural integrity. It is also frequently employed in the construction industry for applications like roofing, wall insulation, and soundproofing, where it provides protection against impacts and external forces. Overall, the impact resistance of fiberglass mat tissue is a key characteristic that contributes to its widespread use in numerous industries. Its ability to withstand impacts and distribute forces makes it a reliable material for applications that require strength, durability, and protection against external forces.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Due to its unique properties and versatility, fiberglass mat tissue is commonly utilized in the manufacturing of composite panels. Its role as a reinforcement material contributes to the enhancement of strength, durability, and overall performance of these panels. In the production process, a sandwich structure is typically formed by incorporating fiberglass mat tissue between layers of resin. This tissue serves as a reinforcing layer, providing added strength and stability to the panels. It effectively distributes applied stress evenly across the panel, thereby reducing the likelihood of cracks or fractures. One notable advantage of fiberglass mat tissue is its ability to enhance the impact resistance of composite panels. By absorbing and dispersing energy when subjected to external forces, it diminishes the risk of damage or breakage. This characteristic makes it a highly suitable choice for applications that necessitate high impact resistance, such as automotive parts, boat hulls, or aircraft components. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion, making it appropriate for usage in environments with high humidity or exposure to chemicals. It acts as a protective barrier, shielding the composite panels from moisture and corrosive substances. As a result, the panels enjoy an extended lifespan and sustained performance. Moreover, fiberglass mat tissue possesses exceptional moldability, which facilitates the creation of intricate shapes and designs. It can be effortlessly molded into various forms, thus offering flexibility in the production process and enabling the fabrication of customized composite panels tailored for specific applications. In summary, fiberglass mat tissue is a vital component in the manufacturing of composite panels. It reinforces the structure, enhances impact resistance, improves corrosion resistance, and enables design flexibility. Its unique properties have made it a favored choice in industries such as construction, transportation, aerospace, and marine, where the demand for high-performance and long-lasting composite panels is prevalent.

- Q: What is the expected lifespan of fiberglass mat tissue in underground applications?

- The expected lifespan of fiberglass mat tissue in underground applications can vary depending on various factors such as the specific conditions of the underground environment, the quality and thickness of the fiberglass mat tissue, and the level of maintenance and care provided. However, on average, fiberglass mat tissue is known for its durability and longevity, making it suitable for underground applications. In general, fiberglass mat tissue is designed to be highly resistant to corrosion, moisture, and other environmental elements commonly found in underground settings. This makes it a reliable choice for applications such as underground pipes, tanks, and other infrastructure where protection against deterioration is crucial. With proper installation and regular maintenance, fiberglass mat tissue can have an expected lifespan of 50 years or more in underground applications. However, it is essential to note that this estimate can vary depending on the specific conditions and usage of the fiberglass mat tissue. To ensure the maximum lifespan of fiberglass mat tissue in underground applications, it is recommended to follow industry best practices, such as proper installation techniques, regular inspections, and addressing any issues, such as cracks or damage promptly. By doing so, the lifespan of fiberglass mat tissue can be extended, providing long-term reliability and durability in underground settings.

- Q: Is fiberglass mat tissue suitable for chemical storage tanks?

- Fiberglass mat tissue is generally considered suitable for chemical storage tanks. Fiberglass itself is known for its excellent chemical resistance properties, making it a popular choice for storing a wide range of chemicals. Additionally, fiberglass mat tissue is typically used as a reinforcement layer in the construction of fiberglass tanks, providing added strength and durability. However, it is important to note that the specific chemical being stored must be taken into consideration. Some highly corrosive or reactive chemicals may require more specialized materials or additional protective coatings to ensure the integrity of the storage tank. Therefore, it is always recommended to consult with a professional engineer or manufacturer to determine the most suitable materials for a specific chemical storage application.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not typically used for making furniture. Fiberglass mat tissue is a lightweight material that is commonly used in industries such as construction, automotive, and aerospace for its strength and durability. It is often used as a reinforcement material in the production of composite materials, such as fiberglass-reinforced plastic (FRP) or fiberglass-reinforced polymers (FRPs). While fiberglass may offer some advantages in terms of strength and resistance to moisture, it is not a commonly used material in furniture manufacturing. Furniture typically requires materials that are aesthetically pleasing, comfortable, and easy to work with. Fiberglass can be difficult to shape, may not provide the desired texture or visual appeal, and can be uncomfortable to sit or lie on. Instead, furniture manufacturers typically utilize materials such as wood, metal, plastic, upholstery fabrics, and foam for creating furniture pieces. These materials offer a wider range of options in terms of design, comfort, and customization, making them more suitable for furniture production.

- Q: Can fiberglass mat tissue be used for insulating ductwork?

- Yes, fiberglass mat tissue can be used for insulating ductwork.

- Q: Can fiberglass mat tissue be used for making surfboards?

- Yes, fiberglass mat tissue can be used for making surfboards. It is a common material used in the construction of surfboards due to its strength, durability, and ability to provide the necessary stiffness and flexibility required for optimal performance in the water.

- Q: Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable. Fiberglass is made from a combination of glass fibers and a binder material, usually resin. When the material is no longer needed or has reached the end of its life cycle, it can be recycled by separating the glass fibers from the binder material. The glass fibers can then be melted down and used to create new fiberglass products, while the binder material can be treated and reused in other applications. Recycling fiberglass mat tissue helps to reduce waste and conserve natural resources, making it an environmentally friendly option.

- Q: How does fiberglass mat tissue perform in terms of dimensional stability?

- Fiberglass mat tissue performs exceptionally well in terms of dimensional stability. Its unique composition of fine fibers and binders helps it maintain its shape and structure even under significant stress or changes in temperature and humidity. This makes it ideal for applications where dimensional stability is crucial, such as in the construction of composite materials, automotive parts, and insulation products.

- Q: Can fiberglass mat tissue be used for insulating metal roofs?

- Indeed, insulating metal roofs is possible with the utilization of fiberglass mat tissue. The thermal properties and durability of fiberglass make it a favored selection for roof insulation. By obstructing heat transfer, it aids in maintaining a cooler interior during scorching weather and a warmer one during chilly weather. Moreover, fiberglass is lightweight and straightforward to install, rendering it a pragmatic choice for metal roofs. Generally, the fiberglass mat tissue is positioned between the metal roof panels and the building's interior, furnishing an efficient insulation layer.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords