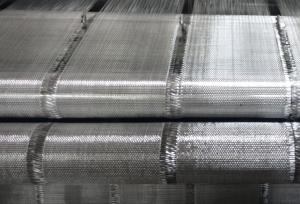

Fiberglass Mat Tissue Woven Roving Combo Fabric for Vehicle Bodies

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

| |||||||||||||||||||||||||||||||||||||||

E-Glass Woven Roving Combo Mat is a complex mat made by stitching together woven roving and a layer of distributed chopped strand. Its main specification is woven roving (300g/m2~900g/m2) with chopped strands (50g/m2~500g/m2)。 The product has a maximum width of 110 inches. This product can be used for boat manufacturing. This mat is a combination of woven roving and chopped glass fiber. The layer of chopped strand is stitched together with woven roving by polyester thread. It is mainly applied in the processes of molding compressing, pultrusion, RTM, filament winding etc..This fabric is compatible with UP Resin, Vinyl ester resin, epoxy resin system etc. It is widely used in vehicle bodies and panels, marine (boat hulls and decks), pipeline, lamination and structural profiles etc. | |||||||||||||||||||||||||||||||||||||||

2.Product Features

| |||||||||||||||||||||||||||||||||||||||

Increase strength, reduce product weight and better surface finish.

| |||||||||||||||||||||||||||||||||||||||

3.Technical Specifications | |||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||

4.FAQ

Packing: | |||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

Storage: | |||||||||||||||||||||||||||||||||||||||

- Q: Can fiberglass mat tissue be used for architectural sculptures?

- Certainly! Fiberglass mat tissue is an ideal choice for architectural sculptures. This versatile material finds extensive use across various applications, including the creation of architectural sculptures. Renowned for its lightweight nature, flexibility, and exceptional strength and durability properties, it proves itself as an excellent option for crafting intricate and detailed sculptures. The beauty of fiberglass mat tissue lies in its ability to be molded and shaped into various forms, enabling artists and sculptors to transform their creative visions into reality. Regardless of the sculpture's size or shape, this material allows for utmost creativity, whether it be a small decorative piece or a large-scale installation. Moreover, fiberglass mat tissue boasts resistance against adverse weather conditions and environmental elements, rendering it suitable for outdoor sculptures. Its capacity to withstand extreme temperature fluctuations, UV radiation, and moisture ensures the sculptures' integrity and aesthetic appeal remain unscathed for an extended period. To further enhance the desired aesthetic appearance, fiberglass mat tissue can be effortlessly painted and finished. The material readily accepts various paints, varnishes, or finishes, providing artists with the means to elevate the visual appeal and safeguard the sculpture's surface against potential damage. All in all, fiberglass mat tissue serves as a reliable and versatile medium for artists and sculptors alike to create architectural sculptures. Its robustness, durability, and adaptability make it an exceptional choice for translating artistic visions into tangible masterpieces within the realm of architecture.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. Fiberglass mat tissue is a lightweight material that has excellent sound absorption properties. It can effectively absorb and dampen sound waves, reducing noise and improving the acoustic environment. Fiberglass mat tissue is commonly used in the construction industry for insulating walls, ceilings, and floors to reduce noise transmission. It is also used in automotive applications and other industries where sound insulation is required. Its high porosity and fibrous structure make it an ideal material for absorbing and attenuating sound waves, making it suitable for acoustic insulation.

- Q: Is fiberglass mat tissue resistant to UV degradation?

- The level of UV resistance in fiberglass mat tissue may vary depending on the specific type and quality. Generally, it is resistant to UV degradation to some extent. UV degradation occurs when materials are exposed to prolonged UV radiation from the sun, causing discoloration, brittleness, and reduced strength. Manufacturers often add additives and coatings to fiberglass mat tissue to provide some level of UV resistance. These additives and coatings protect the fibers from the harmful effects of UV radiation. However, it is important to note that the level of UV resistance can differ between manufacturers and products. To ensure the highest level of UV resistance, it is recommended to select fiberglass mat tissue specifically designed for outdoor applications and tested for UV stability. Additionally, regular maintenance and inspections can help identify any signs of UV degradation and allow for timely repairs or replacements if needed.

- Q: Can fiberglass mat tissue be used for repairing fiberglass kayaks?

- Indeed, the utilization of fiberglass mat tissue is possible for the reparation of fiberglass kayaks. As a lightweight substance, fiberglass mat tissue is frequently employed in the reinforcement and fixing of various fiberglass items, such as kayaks. Its purpose is to readily conform to the contours of the affected region, as it is effortlessly moldable. Through the application of epoxy resin, the fiberglass mat tissue effectively fortifies and adheres to the damaged sections of a fiberglass kayak, thus reviving its sturdiness and endurance. It is imperative to ensure proper preparation of the damaged area and correct application of the fiberglass mat tissue in order to achieve a robust and long-lasting restoration.

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a versatile reinforcement material that offers several advantages over other types of reinforcement materials. Firstly, it has excellent strength and stiffness properties, providing superior load-bearing capabilities compared to other materials. Secondly, fiberglass mat tissue is lightweight, making it easier to handle and install. Additionally, it is highly resistant to corrosion, chemicals, and moisture, ensuring long-term durability. Lastly, fiberglass mat tissue has excellent dimensional stability and is not prone to warping or shrinking, making it a reliable choice for various applications. Overall, its combination of strength, lightweight nature, durability, and dimensional stability sets fiberglass mat tissue apart from other reinforcement materials.

- Q: Can fiberglass mat tissue be used for repairing fiberglass bathtubs?

- Fiberglass bathtubs can be repaired using fiberglass mat tissue. This tissue is a flexible and thin material used to strengthen and reinforce fiberglass surfaces. It is commonly employed in the restoration and repair of various fiberglass products, bathtubs included. To create a durable and sturdy repair, the damaged area is covered with the mat tissue and a layer of resin. This procedure helps fortify weakened or damaged sections of the bathtub, restoring its integrity and preventing further harm. Nevertheless, the success of the repair hinges on the extent of the damage and the expertise of the individual conducting the repair. To achieve optimal results, it is advisable to seek professional advice or adhere to the manufacturer's instructions.

- Q: What is the flexural strength of fiberglass mat tissue?

- The flexural strength of fiberglass mat tissue refers to its ability to resist bending or flexing without breaking. It is typically high due to the reinforcing properties of the fiberglass material, making it suitable for applications requiring structural integrity and resistance to deformation.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. Fiberglass mat tissue is a thin and lightweight material that is typically made from randomly oriented fiberglass strands bonded together with a binder. It is commonly used as a reinforcement material in composite manufacturing processes. When used in composite panel manufacturing, fiberglass mat tissue is typically combined with other materials such as resin and a core material to create a strong and durable panel. The mat tissue provides reinforcement and strength to the panel, helping to distribute loads and prevent cracking or delamination. Fiberglass mat tissue is known for its excellent tensile strength, dimensional stability, and resistance to chemicals, making it well-suited for use in composite panel manufacturing. It can be used in a variety of applications, including construction, transportation, marine, and aerospace industries. Overall, fiberglass mat tissue is a versatile and effective material that can be successfully used in the manufacturing of composite panels. Its properties and characteristics make it a reliable choice for creating strong and durable panels for various applications.

- Q: What is the abrasion resistance of fiberglass mat tissue?

- Fiberglass mat tissue exhibits a relatively high level of abrasion resistance due to its composition. Comprised of finely woven or pressed glass fibers, this material possesses exceptional strength and durability, rendering it highly resistant to abrasion. Consequently, fiberglass mat tissue demonstrates remarkable resilience when exposed to friction or contact with other surfaces, as it remains resistant to wear, tear, or damage. It maintains its structural integrity even under harsh scraping, scratching, or rubbing conditions. As a result, fiberglass mat tissue finds widespread use in various industries, particularly in construction for reinforcing concrete and in composite material manufacturing, where the need for abrasion resistance is paramount.

- Q: Is fiberglass mat tissue suitable for insulation in HVAC ducts?

- Yes, fiberglass mat tissue is suitable for insulation in HVAC ducts. Fiberglass is a commonly used material for insulation due to its excellent thermal and acoustic properties. It is capable of withstanding high temperatures and is resistant to moisture, making it ideal for ductwork applications. Fiberglass mat tissue provides effective insulation by reducing heat transfer and preventing condensation buildup within the ducts. Additionally, it is lightweight, easy to install, and has a long lifespan, making it a cost-effective choice for HVAC insulation. Overall, fiberglass mat tissue is a suitable and reliable option for insulation in HVAC ducts.

Send your message to us

Fiberglass Mat Tissue Woven Roving Combo Fabric for Vehicle Bodies

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords