Glass Wool Insulation Blanket With Aluminum Foil Facing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

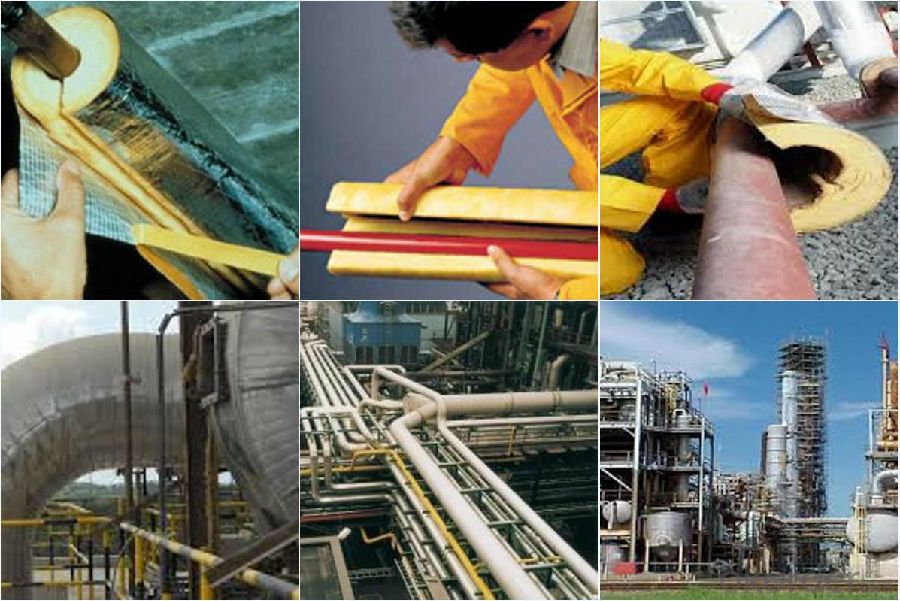

Glass Wool Blanket complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

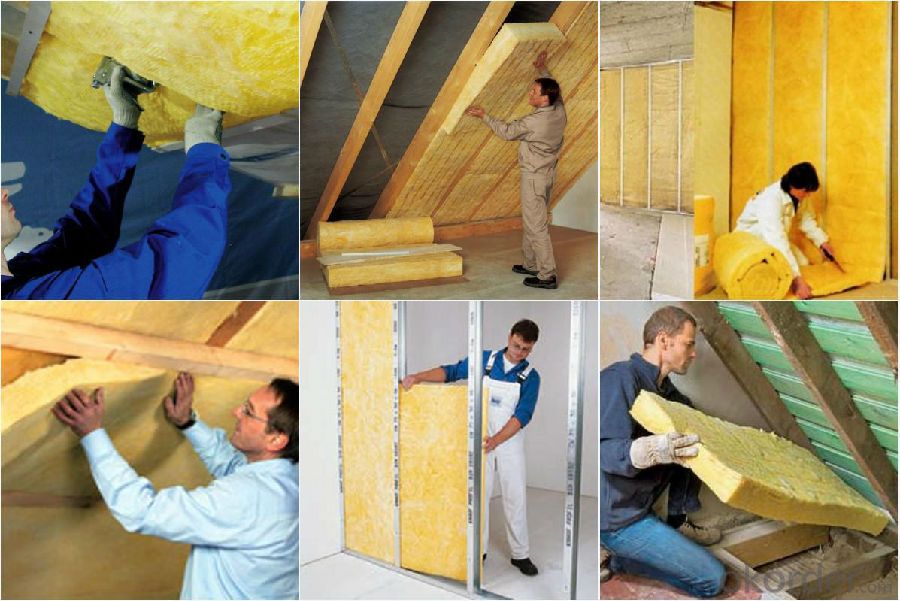

1.Excellent thermal, acoustical properties

2.Light weight and easy to fabricate on job site

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally has good UV resistance. UV resistance refers to the ability of a material to withstand the harmful effects of ultraviolet radiation from the sun without degrading or deteriorating. Fiberglass mat tissue is usually manufactured using a combination of fiberglass and a binder material, which provides strength and integrity to the tissue. The fiberglass component in the mat tissue provides inherent UV resistance. Fiberglass is known for its durability and ability to resist degradation from UV exposure. It is a non-porous material that does not absorb UV radiation, making it less susceptible to damage caused by the sun's rays. Additionally, some manufacturers may apply a UV-resistant coating or treatment to the fiberglass mat tissue to enhance its UV resistance. This coating or treatment can further protect the tissue from the damaging effects of prolonged exposure to UV radiation. Overall, fiberglass mat tissue performs well in terms of UV resistance. It is a durable material that can withstand the harmful effects of UV radiation, making it suitable for applications where prolonged exposure to sunlight is expected. However, it is important to note that the specific UV resistance of fiberglass mat tissue may vary depending on the manufacturing process, quality of materials used, and any additional coatings or treatments applied.

- Q: How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue generally exhibits excellent chemical resistance properties. The material is typically made from glass fibers that are held together by a binder, and this composition allows for resistance to a wide range of chemicals. Fiberglass mat tissue is commonly used as a reinforcement in composite materials, such as fiberglass-reinforced plastics (FRP), due to its ability to withstand exposure to various chemicals without degrading or deteriorating. The chemical resistance of fiberglass mat tissue can vary depending on the specific type and quality of the material, as well as the specific chemical being encountered. However, in general, it is highly resistant to most acids, alkalis, solvents, and other corrosive substances. This resistance makes it a suitable choice for applications where the material may come into contact with aggressive chemicals, such as in chemical processing plants, water treatment facilities, or storage tanks. It is important to note that while fiberglass mat tissue is generally chemically resistant, it may not be completely impervious to all chemicals. Some highly concentrated or specialized chemicals may still have the potential to cause damage or deterioration over time. Therefore, it is always advisable to consult the manufacturer's specifications and recommendations for specific chemical resistance information before using fiberglass mat tissue in a particular application. Overall, fiberglass mat tissue is known for its strong chemical resistance properties, making it a reliable choice for applications where exposure to chemicals is expected.

- Q: Can fiberglass mat tissue be used for insulation in cold environments?

- Indeed, fiberglass mat tissue is a viable option for insulation purposes in frigid settings. Fiberglass, renowned for its remarkable thermal characteristics, is frequently employed as an insulating material. Its capacity to hinder heat transfer is owed to its low thermal conductivity, effectively ensuring insulation in cold environments. Tailored specifically for thermal insulation, fiberglass mat tissue is commonly utilized in various applications such as walls, roofs, and floors to thwart heat dissipation and maintain a cozy indoor temperature. Moreover, fiberglass boasts resistance to moisture and exhibits durability, rendering it impervious to degradation and loss of insulating properties in cold and damp conditions. Consequently, fiberglass emerges as an apt choice for insulation in cold environments.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q: Is fiberglass mat tissue suitable for chemical storage tanks?

- Yes, fiberglass mat tissue is suitable for chemical storage tanks. It is highly resistant to corrosion caused by various chemicals and provides excellent strength and durability to withstand the harsh conditions of chemical storage. Additionally, it helps in preventing leakage and ensures the long-term integrity of the tanks.

- Q: How does fiberglass mat tissue compare to polystyrene insulation?

- Fiberglass mat tissue and polystyrene insulation are two different materials with distinct properties and uses. Fiberglass mat tissue is a woven or non-woven fabric made from glass fibers. It is commonly used as a reinforcement material in various applications such as roofing, pipes, and automotive parts. Fiberglass mat tissue provides excellent strength, durability, and resistance to moisture and chemicals. On the other hand, polystyrene insulation refers to rigid foam boards or expanded polystyrene (EPS) beads used for thermal insulation purposes. Polystyrene insulation offers high thermal resistance, making it an effective material for insulating buildings and reducing energy consumption. Comparing the two, fiberglass mat tissue is primarily used for reinforcement and structural purposes, whereas polystyrene insulation is specifically designed for thermal insulation. The choice between them depends on the specific requirements of the application, such as the need for structural strength or thermal efficiency.

- Q: How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a type of reinforcement material that is commonly used in various industries such as construction, automotive, and marine. When comparing fiberglass mat tissue to other types of reinforcement materials, several factors come into play. Firstly, fiberglass mat tissue offers excellent strength and durability. It has high tensile strength, meaning it can withstand considerable pulling or stretching forces without deforming or breaking. This strength is comparable, if not superior, to other reinforcement materials like carbon fiber or aramid fibers. Additionally, fiberglass mat tissue has good resistance to chemical, moisture, and UV degradation, making it suitable for long-term use in various environments. Another advantage of fiberglass mat tissue is its cost-effectiveness. Compared to other reinforcement materials, fiberglass is relatively inexpensive, making it a popular choice for manufacturers and builders who require a cost-efficient solution without compromising on quality. Its affordability makes it accessible to a wider range of applications and industries. Furthermore, fiberglass mat tissue is known for its versatility. It can be molded into various shapes and sizes, allowing for customization and flexibility in design. This adaptability makes fiberglass mat tissue suitable for a wide range of applications, from simple repairs to complex structural reinforcements. However, it is worth noting that fiberglass mat tissue may have some limitations compared to other reinforcement materials. For instance, it may not have the same level of stiffness or strength as carbon fiber, which is often preferred in high-performance applications. Additionally, fiberglass mat tissue may have lower resistance to impact or fatigue compared to materials like aramid fibers. In conclusion, fiberglass mat tissue offers a combination of strength, durability, cost-effectiveness, and versatility that makes it a favorable choice for many applications. While it may have some limitations compared to other reinforcement materials, its overall performance and affordability make it a widely used and reliable option in various industries.

- Q: Is fiberglass mat tissue suitable for sound absorption?

- Yes, fiberglass mat tissue is suitable for sound absorption. Fiberglass has excellent acoustic properties, making it an effective material for reducing noise levels and improving sound quality in various applications. The fibrous structure of the mat tissue provides a high surface area to absorb sound waves, converting them into heat energy. This makes it an ideal material for soundproofing walls, ceilings, and floors in buildings, as well as for use in automotive, industrial, and marine applications. Additionally, fiberglass mat tissue is lightweight, easy to install, and has good durability and fire resistance, further enhancing its suitability for sound absorption purposes.

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- Various manufacturing processes exist for fiberglass mat tissue, each aiming to create a distinct mat type with unique characteristics. One prevalent method is the wet-laid process. Initially, glass fibers are chopped into small fragments and dispersed in a water-based slurry. This slurry is then spread onto a moving screen or belt, allowing the water to drain off and generating a mat composed of randomly oriented fibers. Subsequently, the mat is dried and further treated to achieve the desired thickness and density. Another technique is the dry-laid process. Here, glass fibers are first transformed into a loose, fluffy mat using either air or mechanical means. Subsequently, the loose fibers are bound together using a binder material, such as resin or latex, which is sprayed onto the fibers. The binder solidifies, resulting in a cohesive mat with controlled thickness and density. A third process is the stitch-bonded process. In this procedure, individual glass fibers are mechanically stitched together using a series of needles. These needles pierce the fibers and interlock them, producing a bonded fabric. This approach enables the production of mats with high strength and dimensional stability. Lastly, the spunbond process involves extruding molten glass through fine spinnerets to create continuous filaments. These filaments are then accumulated onto a moving belt or screen, where they are bonded together using either heat or a binder. This method generates mats with uniform fiber distribution and high strength. In summary, the selection of a manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, including strength, thickness, density, and dimensional stability. Each process possesses its own advantages and disadvantages, and manufacturers will choose the most suitable method based on their specific requirements.

- Q: How does the fiber orientation of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is heavily influenced by the orientation of its fibers. Fiberglass mat tissue is a composite material consisting of glass fibers that are randomly distributed and held together by a binder material. When the fibers are randomly oriented, the material exhibits isotropic strength properties. This means that it has similar mechanical properties, such as tensile strength and stiffness, in all directions. Random fiber orientation provides an even distribution of load-bearing capability throughout the material, making it resistant to both tensile and compressive forces from any direction. Alternatively, when the fibers are oriented in a specific direction, the material becomes anisotropic. This means that it has directional strength properties. In this case, the material is stronger and stiffer along the direction of the fibers, while its strength decreases in other directions perpendicular to the fiber orientation. This anisotropic behavior is due to the fact that the fibers primarily bear the load, while the binder material provides support and cohesion between the fibers. By manipulating the fiber orientation during manufacturing, it is possible to customize the strength and performance characteristics of fiberglass mat tissue for specific applications. For example, in the construction industry, where strength is required in a particular direction for reinforcing concrete, or in the aerospace industry, where structural components need maximum strength along a specific load path, the fibers can be aligned accordingly. In conclusion, the fiber orientation of fiberglass mat tissue directly impacts its strength. Random fiber orientation results in isotropic strength properties, providing balanced strength in all directions. Alternatively, specific fiber alignment creates anisotropic strength properties, allowing for enhanced strength along the direction of the fibers. This ability to control fiber orientation enables the customization of fiberglass mat tissue to meet the specific strength requirements of different industries and applications.

Send your message to us

Glass Wool Insulation Blanket With Aluminum Foil Facing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords