Fiberglass Mat Tissue - Glass Wool Insulation Blanket CNBM Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

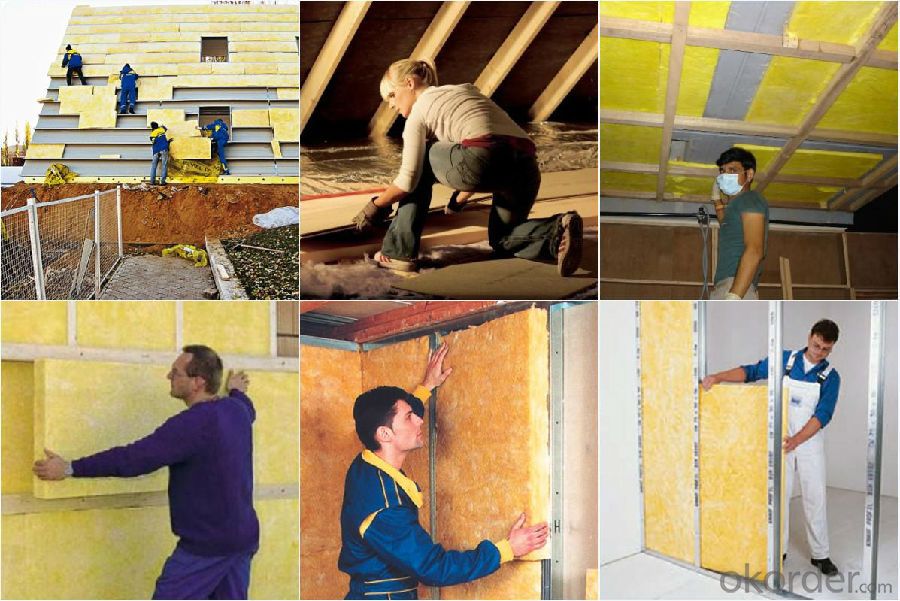

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is fiberglass mat tissue suitable for outdoor applications?

- Yes, fiberglass mat tissue is suitable for outdoor applications. Fiberglass mat tissue is made from woven fiberglass strands that are held together with a binder. This material is highly resistant to water, weather, and UV radiation, making it ideal for use in outdoor environments. It can be used in various outdoor applications such as roofing, insulation, and construction. The waterproof and weatherproof properties of fiberglass mat tissue ensure its durability and longevity when exposed to the elements. Additionally, it is lightweight and easy to handle, making it a versatile choice for outdoor projects.

- Q: Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Indeed, insulation in refrigeration systems can be accomplished by employing fiberglass mat tissue. Fiberglass, renowned for its remarkable thermal characteristics and moisture resistance, is a prevalent choice for insulation purposes. Specifically engineered to provide insulation, fiberglass mat tissue finds frequent application in the construction of refrigeration systems. Its purpose is to reduce heat transfer and uphold the desired temperature within the system. Moreover, fiberglass possesses the advantages of being lightweight, long-lasting, and easily installable, rendering it a favored option for refrigeration system insulation.

- Q: Can fiberglass mat tissue be used for HVAC insulation?

- No, fiberglass mat tissue is not typically used for HVAC insulation. HVAC insulation usually requires materials that are specifically designed to have high thermal resistance and to prevent the transfer of heat or cold air. Fiberglass mat tissue is commonly used as a reinforcement material in the fabrication of composite materials, such as fiberglass panels or structures, rather than as insulation. Insulation materials for HVAC systems are typically made from materials like fiberglass insulation boards, foam insulation, or mineral wool, which have better thermal resistance properties and are specifically designed for HVAC applications.

- Q: Can fiberglass mat tissue be used for waterproofing?

- Yes, fiberglass mat tissue can be used for waterproofing. It is commonly used as a reinforcement material in waterproofing systems, such as for roofs, walls, and foundations. The fiberglass mat tissue is impervious to water and helps to provide an additional layer of protection against moisture intrusion.

- Q: Can fiberglass mat tissue be used for corrosion-resistant coatings?

- Corrosion-resistant coatings can utilize fiberglass mat tissue, a non-woven fabric composed of fine fiberglass strands bonded together using a binder. Due to its exceptional strength and corrosion resistance qualities, fiberglass mat tissue is commonly employed as a reinforcement material in composite applications. When integrated into corrosion-resistant coatings, fiberglass mat tissue acts as a protective barrier against the corrosive surroundings, safeguarding the underlying surface from deterioration caused by chemicals, moisture, and other corrosive substances. Moreover, fiberglass mat tissue can be impregnated with diverse resin systems that enhance its capacity to resist corrosion. These resin systems offer supplementary safeguard against specific corrosive agents or environments, consequently heightening the effectiveness of the coating. Furthermore, the flexibility and moldability of fiberglass mat tissue enable it to conform effortlessly to intricate shapes and surfaces, guaranteeing comprehensive coverage and protection against corrosion. In conclusion, fiberglass mat tissue is a dependable and efficient material for corrosion-resistant coatings. Its impressive strength, corrosion resistance, and compatibility with various resin systems make it a suitable choice for shielding surfaces in corrosive environments.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- Yes, fiberglass mat tissue is suitable for insulation in high-rise buildings. It is commonly used as an insulating material due to its excellent thermal and sound insulation properties. Fiberglass mat tissue is lightweight, fire-resistant, and has a high melting point, making it a safe and effective choice for insulating high-rise buildings. Additionally, it is easy to install and offers good resistance against moisture and mold, ensuring long-term performance and energy efficiency.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- No, fiberglass mat tissue is not suitable for insulation in pharmaceutical storage areas. This material may release particles or fibers that can contaminate the pharmaceutical products, which could compromise their quality and safety. It's essential to use insulation materials that are specifically designed and approved for pharmaceutical storage areas to ensure optimal conditions and adherence to regulatory standards.

- Q: What is the delamination strength of fiberglass mat tissue?

- The delamination strength of fiberglass mat tissue refers to its ability to resist the separation or detachment of layers within the material. This strength is dependent on various factors such as the quality of the resin used, the thickness and density of the mat, and the manufacturing process. Fiberglass mat tissue is typically designed to have a high delamination strength to ensure its durability and structural integrity. The mat is composed of multiple layers of glass fibers held together by a binder or resin. The bonding between these layers is crucial in preventing delamination. The delamination strength of fiberglass mat tissue can be determined through various testing methods, such as the peel test, where the force required to separate the layers is measured. This test provides valuable information about the adhesive strength between the layers and helps in assessing the overall quality of the material. The delamination strength can vary depending on the specific application and requirements. For example, fiberglass mat tissue used in construction or automotive industries may have different delamination strength specifications compared to those used in marine or aerospace applications. Manufacturers typically provide technical data or specifications indicating the delamination strength of their fiberglass mat tissue products. It is important to note that the delamination strength of fiberglass mat tissue can be influenced by external factors such as exposure to extreme temperatures, moisture, or chemical substances. Therefore, proper installation, maintenance, and adherence to recommended usage guidelines are essential to maintaining the desired delamination strength and overall performance of the material.

- Q: Can fiberglass mat tissue be used for repairing fiberglass surfboards?

- Yes, fiberglass mat tissue can be used for repairing fiberglass surfboards. Fiberglass mat tissue is a commonly used material for repairing and reinforcing fiberglass structures, including surfboards. It is lightweight, flexible, and easy to work with, making it ideal for patching up cracks or holes in the surfboard's fiberglass shell. The mat tissue is typically applied with epoxy resin, which bonds the tissue to the surfboard's surface, creating a strong and durable repair. However, it is important to note that the success of the repair depends on the skill and technique of the person performing it. It is recommended to seek professional help or guidance if you are not experienced in surfboard repairs.

- Q: What is the expected lifespan of fiberglass mat tissue in cryogenic applications?

- The expected lifespan of fiberglass mat tissue in cryogenic applications can vary depending on various factors such as the specific temperature, exposure time, and the quality of the material. However, in general, fiberglass mat tissue is known for its durability and resistance to extreme temperatures, making it suitable for long-term use in cryogenic applications. With proper installation and maintenance, it can potentially last for several years or even decades in such environments.

Send your message to us

Fiberglass Mat Tissue - Glass Wool Insulation Blanket CNBM Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords