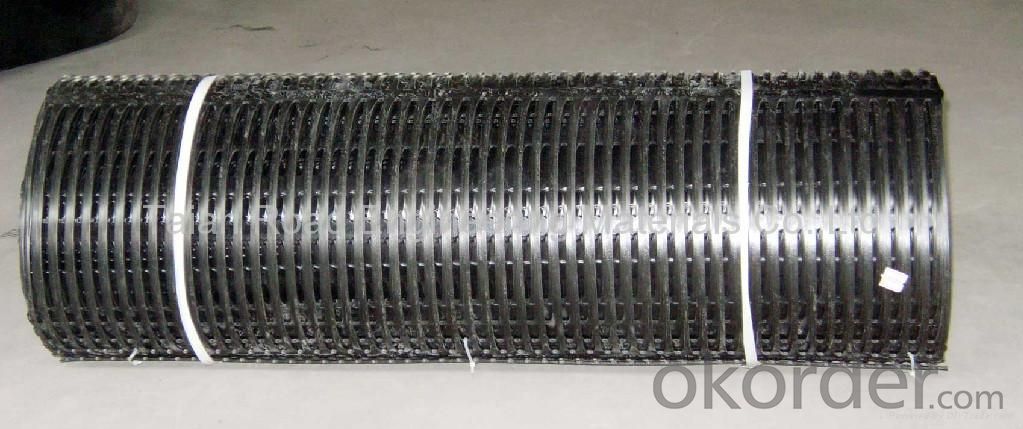

Fiberglass Fabrics from Malaysia Supplier - Fiberglass Geogrid for Airport Road Protection - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

4.FAQ

3 No long-term creep : as a reinforcing material , with the ability to resist deformation under the load in the long-term creep resistance is extremely important, the glass fiber will not creep , to ensure that the products can long-term performance .

- Q: Can fiberglass fabric be used for insulation in pharmaceutical facilities?

- Yes, fiberglass fabric can be used for insulation in pharmaceutical facilities. It is a commonly used material due to its excellent thermal insulation properties, fire resistance, and ability to withstand high temperatures. Additionally, it is lightweight, durable, and cost-effective, making it suitable for various applications in pharmaceutical facilities.

- Q: How is fiberglass fabric repaired?

- Fiberglass fabric can be repaired by using a patching technique. The damaged area is typically cleaned and sanded, and then a suitable adhesive or epoxy resin is applied to attach a fiberglass patch onto the damaged section. The patch is then smoothed out and allowed to cure, ensuring a strong and seamless repair.

- Q: What are the different surface textures available in fiberglass fabric?

- Fiberglass fabric possesses a wide variety of surface textures, each with its own unique properties and advantages. Some examples of these textures include: 1. Plain Weave: This texture is the simplest and most commonly used, featuring a basic over-and-under pattern of fibers. It offers both strength and stability while providing a smooth surface finish. 2. Twill Weave: Twill weave consists of a diagonal pattern created by interlacing fibers. It offers enhanced drapability, better conformability, and increased strength compared to plain weave. Twill weave also provides a distinct appearance. 3. Satin Weave: Satin weave involves floating yarns over multiple warp or weft yarns, resulting in a smooth and lustrous surface. It offers exceptional flexibility, durability, and a high-quality finish. Satin weave is often employed in applications requiring a high level of aesthetics. 4. Leno Weave: Leno weave is characterized by a pair of warp yarns twisting around weft yarns, creating an open mesh structure. This texture improves breathability, facilitates resin saturation, and offers good drapability. Leno weave is commonly used in applications where air circulation or filtration is crucial. 5. Jacquard Weave: Jacquard weave involves intricate patterns created by individually controlling each warp yarn. It allows for the weaving of elaborate designs and textures into the fabric. Jacquard weave is frequently used for decorative purposes or when specific patterns are required. Each surface texture in fiberglass fabric is tailored to meet the specific requirements of various applications, including aerospace, automotive, marine, construction, and industrial sectors. The choice of texture depends on factors such as the desired strength, flexibility, aesthetics, and functionality needed for a particular application.

- Q: What is the best waterproof material for swimming pool?

- Hard waterproof: the whole swimming pool is made of waterproof concrete;

- Q: Can fiberglass fabric be used for reinforcement in marine applications?

- Yes, fiberglass fabric can be used for reinforcement in marine applications. Fiberglass fabric is a popular choice for reinforcing and strengthening various parts of boats and other marine structures. It is known for its high strength-to-weight ratio, making it an ideal material for improving the structural integrity of marine components. Fiberglass fabric is commonly used to reinforce hulls, decks, bulkheads, and other parts of boats. It is also used in the construction of sailboats, powerboats, yachts, and other watercraft. The fabric can be applied in multiple layers, providing additional strength and durability. One of the key advantages of fiberglass fabric in marine applications is its resistance to water and corrosion. It does not absorb water, making it highly suitable for marine environments where exposure to moisture, saltwater, and other harsh conditions is common. Fiberglass fabric is also resistant to UV radiation, which is crucial for maintaining the structural integrity and appearance of marine components. Furthermore, fiberglass fabric offers excellent dimensional stability, meaning it can retain its shape and strength over time. This is especially important in marine applications where boats and structures are subjected to constant movement, vibrations, and varying loads. In summary, fiberglass fabric is a versatile and reliable material for reinforcing marine applications. Its high strength-to-weight ratio, resistance to water and corrosion, and excellent dimensional stability make it a popular choice among boat builders and marine engineers.

- Q: How does fiberglass fabric handle repeated flexing and stretching?

- Fiberglass fabric is known for its exceptional durability and ability to withstand repeated flexing and stretching. Due to its inherent flexibility and high tensile strength, fiberglass fabric can handle these mechanical stresses without significant damage or loss of performance. The interwoven fiberglass strands provide the fabric with excellent resistance to compression, bending, and stretching, making it highly suitable for applications that require repetitive motion or dynamic loads. Additionally, the unique properties of fiberglass, such as its low coefficient of thermal expansion and high resistance to chemicals and moisture, further contribute to its ability to handle repeated flexing and stretching. Overall, fiberglass fabric is a reliable and robust material that can withstand the demands of various industries and applications.

- Q: Is fiberglass fabric resistant to chemicals in chemical processing plants?

- Fiberglass fabric, in general, exhibits resistance to chemicals commonly found in chemical processing plants. Its chemical resistance properties are well-known, making it a popular choice in various industrial settings, including chemical processing plants. Fiberglass demonstrates high resistance to a diverse range of chemicals, such as acids, alkalis, solvents, and other corrosive substances prevalent in chemical plants. This exceptional resistance contributes to the reliability and durability of fiberglass fabric as a construction material for equipment, piping, tanks, and other components in chemical processing plants. However, it is crucial to take into account the specific type and concentration of chemicals being handled when selecting the appropriate fiberglass fabric to ensure optimal chemical resistance.

- Q: Is fiberglass fabric resistant to chemicals used in agriculture?

- In agriculture, fiberglass fabric is typically resistant to the chemicals commonly used. Fiberglass is renowned for its outstanding resistance to chemicals, making it a suitable material for diverse agricultural applications. It can endure exposure to a broad spectrum of chemicals, including fertilizers, pesticides, herbicides, and other agrochemicals. This resistance to chemicals guarantees the fabric's durability and shields it from the corrosive nature of these substances. Moreover, fiberglass fabric is also impervious to moisture, UV radiation, and extreme temperatures, rendering it a dependable option for agricultural purposes in environments with harsh conditions.

- Q: Can fiberglass fabric be used for tents and awnings?

- Certainly, tents and awnings can be made using fiberglass fabric. This material is widely preferred for outdoor use because of its resilience, robustness, and ability to withstand extreme weather conditions. Despite being lightweight, it is remarkably sturdy, making it an optimal choice for constructing tents and awnings. Furthermore, fiberglass fabric possesses fire-resistant qualities and offers exceptional UV protection, ensuring a secure and pleasant outdoor experience. It also boasts excellent insulation properties, which help maintain a comfortable temperature inside the tent or beneath the awning. All in all, fiberglass fabric is a dependable and versatile option for tents and awnings, delivering both protection and endurance in diverse outdoor environments.

- Q: Can fiberglass fabric be used for gaskets?

- Yes, fiberglass fabric can be used for gaskets. It is a versatile material that offers good resistance to high temperatures, chemicals, and mechanical stress. Additionally, fiberglass fabric can provide excellent sealing properties, making it suitable for various gasket applications.

Send your message to us

Fiberglass Fabrics from Malaysia Supplier - Fiberglass Geogrid for Airport Road Protection - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords