High Strength Fiberglass Geogrids from Thailand Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

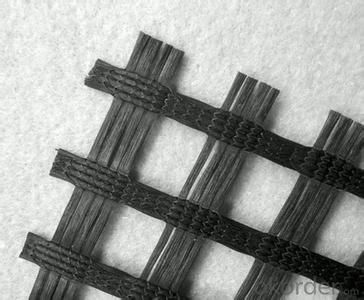

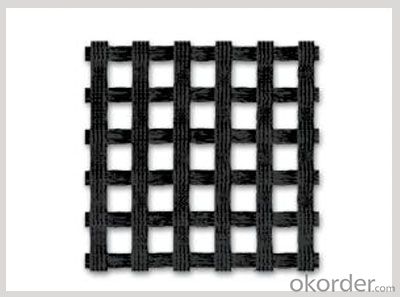

CMAX fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

Performance:

High strength, high modulus and low temperatures resistance

Applications:

Reinforcement for road pavement

Reinforcement for railway basement

Reinforcement for Tunnel

Reinforcement for slope

Reinforcement for embankment.

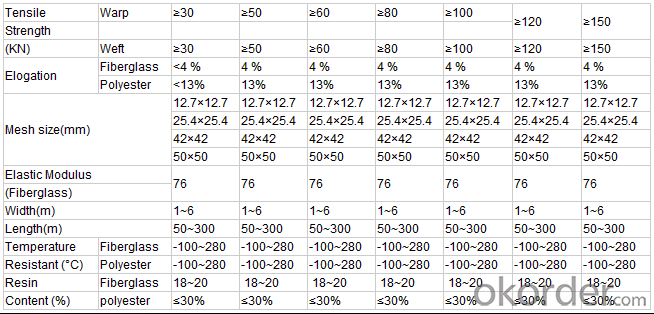

Specifications:

Packing

FAQ

●How long have you been in international trade and geosynthetics industry?

10-year experience in international trade.

20-year experience in geosynthetics field.

●Which payment do you accept?

For you convinience,our payment can be L/C,TT,Westunion,paypal

●Can I know the width you can produce?

Of course we can,our width can be 1 to 6m

●How will you pack the products?

Usually we pack our products by woven bags,also we can do as your requirements

●We want to make sure quality,is free sample available?

We can supply free samples if you need.

- Q: Can geogrids be used in environmental containment systems?

- Yes, geogrids can be used in environmental containment systems. Geogrids are often used as reinforcement in these systems to prevent soil erosion and maintain the stability of containment structures, such as landfills or retention ponds. They enhance the overall strength and performance of the containment system, making them an effective solution for environmental protection.

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, project requirements, and installation method. It is essential to consult with geotechnical engineers or geosynthetic specialists who can analyze the specific project needs and recommend the most suitable geogrid aperture shape, which can range from square to rectangular or triangular.

- Q: How do geogrids improve the performance of retaining walls?

- Geogrids improve the performance of retaining walls by providing reinforcement and stability. They are typically made of high-strength materials and are installed within the soil mass behind the wall. These grids distribute the loads exerted on the wall more evenly, reducing the pressure on the wall itself. This reinforcement prevents excessive movement, soil erosion, and potential wall failure. Additionally, geogrids enhance the overall strength and durability of the retaining structure, allowing for the construction of taller and more efficient walls.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement and stability to the soil structure. They restrain the lateral movement and spread the load more evenly, preventing excessive settlement.

- Q: Who can say the geogrid, fiberglass mesh and geotextile what is the difference, from the material function, the use of all aspects of speaking, if the answer is good, I add the score

- Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention, protection, light weight, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance. Common non-woven fabric, consider the use of water inside the polyethylene polypropylene fiber waterproof is also used

- Q: What are the factors that affect the installation quality of geogrids?

- There are several factors that can affect the installation quality of geogrids. Some of the key factors include the proper selection and preparation of the subgrade, accurate placement and alignment of the geogrid, appropriate tensioning and anchoring of the geogrid, and the overall construction practices followed during installation. Additionally, factors such as weather conditions, soil type, and site-specific requirements can also impact the installation quality of geogrids.

- Q: Are geogrids suitable for use in mechanically stabilized bridge abutments?

- Yes, geogrids are suitable for use in mechanically stabilized bridge abutments. Geogrids provide reinforcement and stability to the soil, allowing for increased load-bearing capacity and reduced settlement. They are commonly used in bridge abutments to improve the overall performance and longevity of the structure.

- Q: How do geogrids enhance the performance of geosynthetic clay liner drainage systems?

- Geogrids enhance the performance of geosynthetic clay liner drainage systems by providing additional reinforcement and stability. By placing geogrids between layers of clay liner, it helps to distribute the load evenly and prevent the liner from shifting or slipping. This enhances the overall strength and integrity of the drainage system, ensuring efficient water flow and preventing soil erosion.

- Q: What are the long-term durability characteristics of geogrids?

- Geogrids have excellent long-term durability characteristics. They are designed to withstand harsh environmental conditions, including high temperatures, moisture, and chemical exposure. Geogrids are made from high-strength materials, such as polyester or polypropylene, which provide resistance against degradation and maintain their structural integrity over time. They have a long service life and can effectively retain soil, stabilize slopes, and reinforce paved surfaces for many years without significant deterioration.

- Q: Can geogrids be used in coastal protection?

- Yes, geogrids can be used in coastal protection. Geogrids are commonly used in various coastal protection measures such as shoreline stabilization, erosion control, and sea defense structures. They provide reinforcement and stability to coastal soil and structures while allowing for proper drainage and vegetation growth. Geogrids help to prevent erosion and mitigate the impacts of waves, tides, and storm surges, making them an effective solution for coastal protection.

Send your message to us

High Strength Fiberglass Geogrids from Thailand Supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 150000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords