Fiberglass Geogrid with High Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

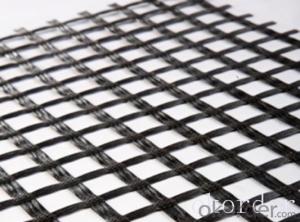

The outlook of the biaxial geogrid is net work structure like a square. It uses polyester as its raw material and is made of high molecular polymer through extrusion, formed and punched before longitudinally and laterally stretched. This kind of material has a high tensile longitudinally and horizontally, which can be used to reinforce the basement.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geogrids be used in reinforced concrete structures?

- Yes, geogrids can be used in reinforced concrete structures. Geogrids are commonly used as a reinforcing material in concrete structures to enhance their load-bearing capacity and reduce cracking. They provide additional tensile strength and help distribute the applied loads more efficiently, improving the overall structural performance.

- Q:How to read geogrid grilleBe careful not to copy the dictionary. I want to know why he read it hereI look at the dictionary said: the gate of zhBlock made of bamboo, iron bars, etc.. barsIs it because geogrid can also be seen as a strip of things, so read Zha

- Geogrid, a kind of geosynthetic material used for reinforcement, which is formed by a regular mesh tension band

- Q:What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are two different types of geosynthetics used in various civil engineering and environmental applications. Geogrids are typically made of high-strength polymer materials, such as polypropylene or polyester, and are designed to provide reinforcement and stabilization to soil structures. They have a grid-like structure with open apertures, allowing soil particles to interlock within the grid, improving load distribution and preventing soil erosion. Geogrids are commonly used in slope stabilization, retaining walls, and road construction. On the other hand, geosynthetic clay liners (GCLs) are composite materials consisting of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is highly absorbent and expands upon contact with water, creating a low permeability barrier. GCLs are primarily used as hydraulic barriers for containment applications, such as landfill liners, pond liners, and wastewater treatment facilities. They provide excellent resistance to liquid flow and act as a barrier to prevent the migration of contaminants. In summary, the main differences between geogrids and geosynthetic clay liners lie in their composition, purpose, and applications. Geogrids focus on soil reinforcement and stabilization, while GCLs are primarily used as barriers to control liquid flow and prevent the migration of contaminants.

- Q:What is the typical thickness of a geogrid?

- The typical thickness of a geogrid can vary depending on the specific application and manufacturer. However, most geogrids range in thickness from 0.5 to 3 millimeters.

- Q:How do geogrids reduce the amount of fill required for construction?

- Geogrids reduce the amount of fill required for construction by providing soil reinforcement and improving the stability of the earthwork. They distribute the load more evenly across the soil, thereby allowing for the use of less fill material while still maintaining the necessary structural integrity.

- Q:Do geogrids reduce the amount of fill material required?

- Yes, geogrids can reduce the amount of fill material required. Geogrids are designed to improve soil stability and reinforce the fill material. By distributing the load more efficiently, geogrids allow for the use of thinner layers of fill material, thus reducing the overall amount needed. This can result in cost savings and more sustainable construction practices.

- Q:What are the design considerations for geogrids in mechanically stabilized earth walls?

- The design considerations for geogrids in mechanically stabilized earth walls include factors such as the required strength and stiffness of the geogrid material, the appropriate selection of geogrid type (uniaxial or biaxial), the spacing and orientation of the geogrid layers, and the connection and anchoring methods between the geogrid and the wall facing. Other considerations may include the soil characteristics, slope stability, and potential loads or forces acting on the wall. Overall, the design aims to maximize the geogrid's reinforcement effect and ensure the stability and durability of the mechanically stabilized earth wall.

- Q:Who has the "highway geosynthetics geogrid" specification

- JT/T925.1 2017 highway engineering geosynthetics

- Q:How do geogrids help in reducing settlement of foundations?

- Geogrids help in reducing settlement of foundations by providing reinforcement and stability to the soil. They distribute the load more evenly, preventing differential settlement and soil consolidation. Additionally, geogrids increase the tensile strength of the soil, minimizing deformation and settlement over time.

- Q:How do geogrids enhance the stability of steep slopes?

- Geogrids enhance the stability of steep slopes by providing reinforcement and increasing the tensile strength of the soil. They act as a barrier, distributing the load and preventing soil erosion. This reinforcement helps to prevent slope failure and ensures the long-term stability of the slope.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with High Strength Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords